Introduction

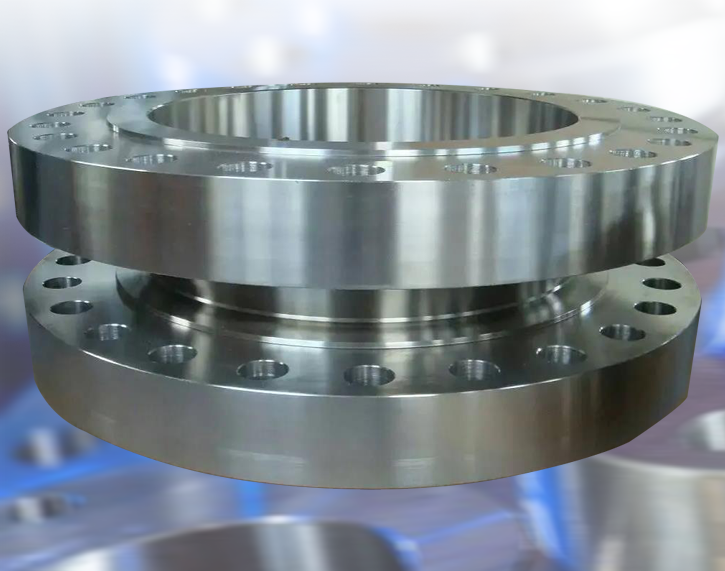

Flange fittings play a crucial role in the efficient and reliable operation of piping systems. They serve as connectors, joining different sections of pipes or tubes, and allow for easy assembly, disassembly, and maintenance. Flanges provide a secure and leak-proof connection, ensuring the smooth flow of fluids or gases within a system.

Understanding the differences between ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers) flanges is essential for professionals involved in the design, construction, and maintenance of piping systems. ANSI and ASME flanges have distinct characteristics and specifications that determine their compatibility with specific applications.

Proper selection and application of flanges are paramount to ensuring the integrity and safety of a piping system. By understanding the differences between ANSI and ASME flanges, engineers and technicians can make informed decisions, considering factors such as design standards, dimensions, pressure ratings, and materials. This comprehensive guide will delve into the nuances of ANSI and ASME flanges, empowering readers to select the most suitable flange fittings for their specific requirements.

What are ANSI Flanges?

ANSI flanges, also known as American National Standards Institute flanges, are widely used in various industries for connecting pipes and equipment in a piping system. ANSI is an organization that develops and publishes standards for a wide range of industries in the United States. ANSI flanges conform to specific standards and specifications set by ANSI, ensuring compatibility and interchangeability.

Standards and Classifications of ANSI Flanges:

- ANSI B16.5: This standard covers flanges with nominal sizes ranging from 1/2 inch to 24 inches. ANSI B16.5 flanges are commonly used in applications involving low to moderate pressure and temperature. They are available in various face types, such as raised face (RF), flat face (FF), and ring-type joint (RTJ).

- ANSI B16.47: This standard is divided into two parts: ANSI B16.47 Series A and ANSI B16.47 Series B. Series A flanges are larger and have higher pressure ratings, typically used in high-pressure and high-temperature applications. Series B flanges have smaller sizes and lower pressure ratings, suitable for lower-pressure applications. Both Series A and Series B flanges are available in RF and RTJ-facing types.

- ANSI B16.36: This standard specifies orifice flanges, which are used in applications where the flow of fluids or gases needs to be measured or controlled. Orifice flanges have a smaller bore diameter and include a removable orifice plate.

- ANSI B16.48: This standard covers flanges used for connecting pipes or equipment with different nominal sizes and ratings. These flanges, known as spectacle blinds or paddle blinds, provide a positive shutoff by rotating the blind to block or allow flow.

- ANSI B16.1: This standard addresses cast iron pipe flanges and flanged fittings. Cast iron flanges are commonly used in low-pressure applications and offer excellent corrosion resistance and durability.

The classifications of ANSI flanges are typically based on pressure ratings, facing types, and dimensions. Pressure ratings range from class 150 to class 2500, indicating the maximum pressure the flanges can withstand. Facing types include RF, FF, and RTJ, each suited for different sealing requirements. Dimensions, such as flange diameter, bolt circle diameter, and number of bolt holes, vary depending on the flange size and class.

Understanding the standards and classifications of ANSI flanges is crucial for selecting the appropriate flanges that meet specific application requirements and ensure compatibility within a piping system.

To know more please check: The Complete Guide to ANSI Flanges: Types, Standards, Sizes, Materials, and Applications

What are ASME Flanges?

ASME flanges, also known as the American Society of Mechanical Engineers flanges, are widely recognized and used in various industries globally. ASME is a professional organization that develops and publishes codes and standards for mechanical engineering practices, including piping systems. ASME flanges adhere to specific standards and guidelines set by the ASME, ensuring their reliability, safety, and performance in critical applications.

Standards and Classifications of ASME Flanges:

- ASME B16.5: This standard covers flanges with nominal sizes ranging from 1/2 inch to 24 inches. ASME B16.5 flanges are commonly used in applications involving moderate pressure and temperature. They are available in various face types, such as raised face (RF), flat face (FF), and ring-type joint (RTJ).

- ASME B16.47: This standard is divided into two parts: ASME B16.47 Series A and ASME B16.47 Series B. Series A flanges are larger and have higher pressure ratings, typically used in high-pressure and high-temperature applications. Series B flanges have smaller sizes and lower pressure ratings, suitable for lower-pressure applications. Both Series A and Series B flanges are available in RF and RTJ-facing types.

- ASME B16.36: This standard specifies orifice flanges, which are used in applications where the flow of fluids or gases needs to be measured or controlled. Orifice flanges have a smaller bore diameter and include a removable orifice plate.

- ASME B16.48: This standard covers flanges used for connecting pipes or equipment with different nominal sizes and ratings. These flanges, known as spectacle blinds or paddle blinds, provide a positive shutoff by rotating the blind to block or allow flow.

- ASME B16.1: This standard addresses cast iron pipe flanges and flanged fittings. Cast iron flanges are commonly used in low-pressure applications and offer excellent corrosion resistance and durability.

The classifications of ASME flanges are typically based on pressure ratings, facing types, and dimensions. Pressure ratings range from class 150 to class 2500, indicating the maximum pressure the flanges can withstand. Facing types include RF, FF, and RTJ, each suited for different sealing requirements. Dimensions, such as flange diameter, bolt circle diameter, and number of bolt holes, vary depending on the flange size and class.

Understanding the standards and classifications of ASME flanges is vital for selecting the appropriate flanges that meet specific application requirements and comply with the recognized industry standards established by the ASME.

To know more please check: AMSE Flanges: A Comprehensive Guide to Selection and Application

Differences Between ANSI and ASME Flanges

The difference between ANSI flanges and ASME flanges is mainly in the following aspects:

- Design Standards:

- ANSI Flanges: ANSI flanges follow the standards and specifications set by the American National Standards Institute (ANSI). These standards are widely recognized in the United States and certain regions.

- ASME Flanges: ASME flanges adhere to the codes and standards established by the American Society of Mechanical Engineers (ASME). These standards have global recognition and are widely adopted in various industries worldwide.

- Dimensions:

- ANSI Flanges: ANSI flanges are available in a wide range of sizes, with nominal sizes ranging from 1/2 inch to 24 inches. They have specific dimensions and bolt-hole patterns based on the flange size and class.

- ASME Flanges: ASME flanges also come in various sizes, following the same nominal size range as ANSI flanges. The dimensions, including flange diameter, bolt circle diameter, and the number of bolt holes, are specified based on the flange size and class.

- Pressure Ratings:

- ANSI Flanges: ANSI flanges have pressure ratings ranging from class 150 to class 2500. The pressure rating indicates the maximum pressure the flange can withstand under specific operating conditions.

- ASME Flanges: ASME flanges also have pressure ratings ranging from class 150 to class 2500, similar to ANSI flanges. The pressure ratings determine the maximum pressure the flange can handle within defined parameters.

- Material Standards:

- ANSI Flanges: ANSI flanges are designed to accommodate various materials such as carbon steel, stainless steel, and alloy steel. The material standards may vary based on specific project requirements.

- ASME Flanges: ASME flanges also support a wide range of materials, including carbon steel, stainless steel, and alloy steel. The material standards comply with the specifications defined by the ASME.

- Global Recognition:

- ANSI Flanges: ANSI flanges are primarily recognized and commonly used within the United States and certain regions where ANSI standards are adopted.

- ASME Flanges: ASME flanges enjoy global recognition and acceptance due to the widespread use of ASME codes and standards in numerous industries worldwide.

It is important to note that while there are differences between ANSI and ASME flanges in terms of design standards, dimensions, pressure ratings, and global recognition, both types of flanges serve the purpose of connecting pipes and equipment in piping systems. The selection of the appropriate flange type depends on the specific application requirements and adherence to relevant standards and specifications.

Applications and Selection Guidelines

Selecting the correct flange is crucial for ensuring the integrity, safety, and efficiency of a piping system. Here are some important factors to consider and recommendations to help readers choose the appropriate flange based on specific application scenarios:

- Operating Conditions:

- Consider the temperature, pressure, and medium (fluid or gas) involved in the application. Higher pressure and temperature requirements may necessitate the use of flanges with higher pressure ratings and materials capable of withstanding specific conditions.

- Compatibility:

- Ensure compatibility between the flange and the pipe or equipment being connected. Consider factors such as pipe size, material, and facing type to ensure a proper fit and sealing capability.

- Standards and Regulations:

- Adhere to relevant industry standards and regulations applicable to the specific application. ANSI and ASME flanges comply with recognized standards, but regional or project-specific requirements may influence the choice of flange type.

- Material Selection:

- Evaluate the chemical compatibility of the flange material with the medium being transported. Consider factors such as corrosion resistance, temperature limitations, and mechanical properties to select a suitable material (e.g., carbon steel, stainless steel, or alloy steel).

- Design Considerations:

- Assess the design requirements of the piping system, including the need for flexibility, stress distribution, and accessibility for maintenance and inspection. Special flange types, such as orifice flanges or spectacle blinds, may be necessary for specific applications.

- Sealing Requirements:

- Determine the sealing requirements based on the operating conditions and the medium being transported. Raised face (RF) flanges are commonly used for general-purpose applications, while ring-type joint (RTJ) flanges provide enhanced sealing capabilities for high-pressure or corrosive environments.

- Industry Expertise:

- Consult with industry experts, engineers, or reputable flange manufacturers to gain insights and recommendations specific to the application requirements. Their expertise can help in selecting the most suitable flange type and ensuring compliance with applicable standards.

By considering these factors and recommendations, readers can make informed decisions when selecting the appropriate ANSI or ASME flange for their specific requirements. It is essential to prioritize safety, reliability, and long-term performance while taking into account the specific demands of the application.

To know more please check: Which Flange Type is Right for Your Application: ANSI or ASME?

Manufacturing Process of Flange Fittings

The manufacturing process of flange fittings involves several steps, including material selection, machining, and testing. Each stage is crucial to ensuring the quality, reliability, and performance of the final product. Here is an overview of the manufacturing process:

- Material Selection:

- The process begins with selecting the appropriate material for the flange fittings. Common materials include carbon steel, stainless steel, and alloy steel, chosen based on the application requirements, including temperature, pressure, and corrosion resistance.

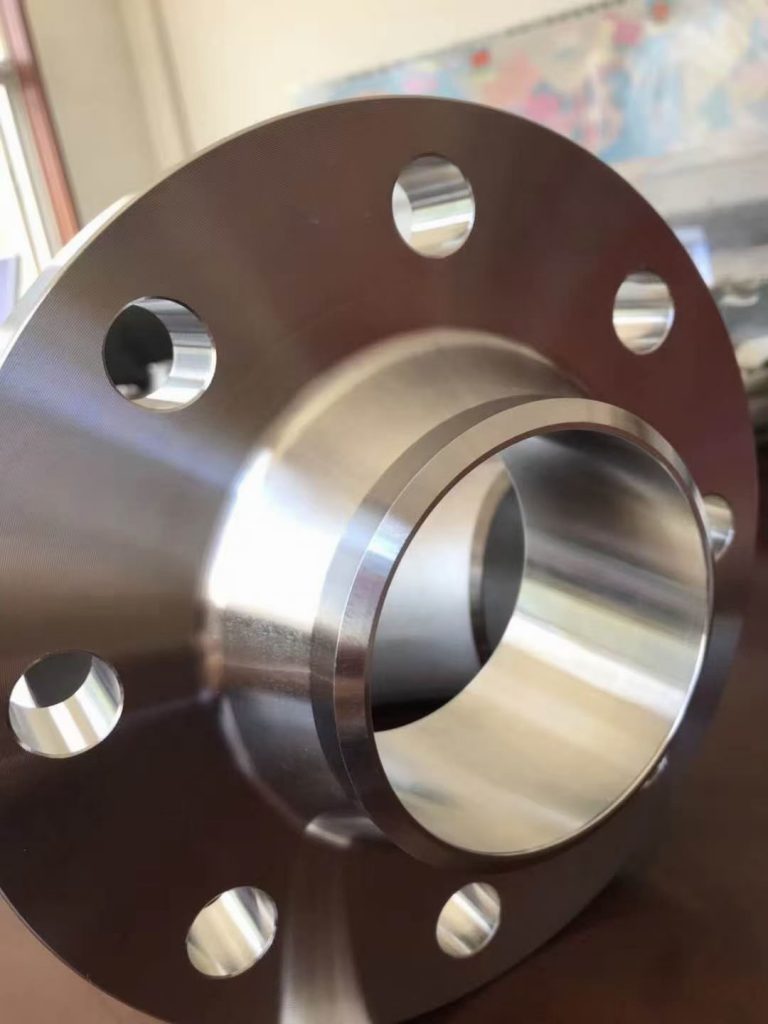

- Machining:

- Machining involves shaping the raw materials into the desired flange fittings. The specific machining processes may vary but generally include the following steps: a. Cutting: Raw materials are cut into appropriate sizes using techniques such as shearing, sawing, or laser cutting. b. Forming: The flange blanks are formed through methods like forging, casting or rolling to achieve the required shape and dimensions. c. Machining: Various machining operations, such as turning, milling, drilling, and threading, is performed to refine the flange dimensions, bolt-hole patterns, and facing surfaces.

- Heat Treatment:

- Depending on the material and specific application requirements, heat treatment processes like annealing, normalizing, or quenching and tempering may be employed to enhance the mechanical properties and structural integrity of the flange fittings.

- Surface Treatment:

- Surface treatment methods, such as shot blasting, grinding, or polishing, are employed to improve the surface finish, remove any imperfections, and enhance the overall aesthetics of the flange fittings.

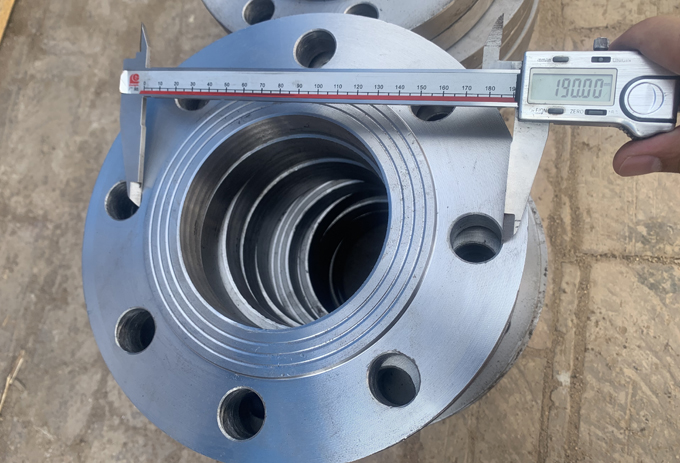

- Quality Control and Testing:

- Quality control is a critical aspect of the manufacturing process. Flange fittings undergo rigorous testing and inspection to ensure they meet the required standards and specifications. Some common tests include a. Dimensional Inspection: Verifying the flange dimensions, bolt-hole patterns, and facing surfaces. b. Non-Destructive Testing (NDT): Techniques like ultrasonic testing, liquid penetrant testing, or magnetic particle inspection are used to detect any defects or discontinuities in the flange fittings. c. Pressure Testing: Flange fittings undergo hydrostatic or pneumatic pressure testing to assess their ability to withstand the specified pressure levels without leakage. d. Material Analysis: Chemical composition analysis and mechanical property testing ensure the material meets the required standards. e. Certification: Flange fittings that pass all quality tests and inspections are issued certifications, such as ISO 9001, ASME certification, or pressure vessel manufacturing licenses, to attest to their quality and compliance.

Emphasis on Quality Management and Certifications: Quality management is of paramount importance in the manufacturing of flange fittings. Implementing robust quality control measures, adhering to international standards, and obtaining relevant certifications demonstrate a commitment to product excellence and customer satisfaction. Certifications such as ISO 9001, ASME certification, or pressure vessel manufacturing licenses validate the manufacturer’s adherence to strict quality standards, ensuring that the flange fittings meet the required specifications and perform reliably in demanding applications.

Testing and Compliance

Flange fittings undergo various testing methods to ensure their quality, integrity, and compliance with industry standards. Three key testing methods for flange fittings are non-destructive testing, heat treatment, and hydrostatic testing. Additionally, complying with ISO9001:2000 quality management system certification and pressure piping component manufacturing licenses is crucial for demonstrating a commitment to quality and meeting regulatory requirements.

- Non-Destructive Testing (NDT): Non-destructive testing techniques are used to inspect flange fittings without causing damage to the product. Common NDT methods include:

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws, such as cracks or voids, ensuring the integrity of the flange fittings.

- Liquid Penetrant Testing (PT): Involves applying a liquid penetrant that seeps into surface cracks, which is then made visible by applying a developer. This method helps detect surface-level defects.

- Magnetic Particle Inspection (MPI): Uses magnetic fields and iron particles to identify surface or near-surface flaws, such as cracks or discontinuities, in ferromagnetic materials.

- Heat Treatment: Heat treatment is a controlled process used to alter the mechanical and physical properties of flange fittings. It helps improve their strength, hardness, and resistance to wear or corrosion. Common heat treatment methods include:

- Annealing: Heating the flange fittings to a specific temperature and then gradually cooling them to relieve internal stresses and improve machinability.

- Normalizing: Heating the flange fittings above their critical temperature, followed by air cooling, to refine the microstructure and enhance the mechanical properties.

- Quenching and Tempering: Rapidly cooling the flange fittings after heating them and then reheating them to a lower temperature to achieve specific hardness, strength, and toughness.

- Hydrostatic Testing: Hydrostatic testing evaluates the strength and integrity of flange fittings by subjecting them to water or another suitable fluid under high pressure. This test ensures that the flange fittings can withstand the designated pressure without leakage or failure.

Importance of Compliance: Complying with ISO9001:2000 quality management system certification demonstrates a commitment to consistently providing high-quality products and services. This certification establishes effective quality management processes, including documentation control, process control, and customer satisfaction measurement.

Additionally, obtaining pressure piping component manufacturing licenses ensures compliance with regulatory requirements for manufacturing flange fittings used in pressure piping systems. These licenses verify that the manufacturer meets specific quality and safety standards set by relevant authorities or organizations.

By adhering to ISO9001:2000 certification and obtaining pressure piping component manufacturing licenses, manufacturers demonstrate their dedication to producing flange fittings that meet stringent quality standards, regulatory compliance, and customer expectations. These certifications instill confidence in customers, ensuring that the flange fittings they receive are of high quality, reliable, and suitable for their intended applications.

Competitive Advantages of YANHAO Company

YANHAO Company, based in Cangzhou, Hebei, China, is a prominent flange processing manufacturer with several competitive advantages that set it apart in the industry. Here are the key advantages of YANHAO:

- Superior Quality: YANHAO Company places a strong emphasis on delivering high-quality flange products. The company has implemented a comprehensive quality management system, including physical and chemical testing, non-destructive testing, heat treatment, and hydrostatic testing. These measures ensure that the flange fittings meet rigorous quality standards and exhibit excellent performance and durability.

- Competitive Pricing: YANHAO Company offers competitive pricing for its flange products. With its location in China, where manufacturing costs are generally lower, and leveraging the advantages of the local flange industry in Hebei, known as the “Flange Hometown” of China, the company can provide cost-effective solutions without compromising on quality.

- Strong Supply Chain Advantages: Situated in Hebei, YANHAO benefits from a robust and efficient supply chain network. The region is home to renowned steel suppliers like Baosteel Group, Laigang Group, Tianjin Steel Factory, and Qingshan Steel Factory. This strategic location ensures a reliable and timely supply of high-quality raw materials, enabling YANHAO to maintain consistent production and delivery schedules.

- Customization Capabilities: YANHAO excels in meeting customers’ unique requirements by offering extensive custom flange capabilities. The company can produce flange fittings according to non-standard specifications and accommodate large-sized flange fittings. With advanced equipment such as the Φ1020mm large-diameter medium-frequency hydraulic extrusion press, Φ1420mm large-diameter medium-frequency hot-bending machine, and Φ2438 four-thousand-ton large-scale hot mold pressure machine, YANHAO can fulfill diverse customer needs.

- Advanced Equipment: YANHAO is equipped with state-of-the-art machinery and equipment to ensure precise manufacturing and superior product quality. The company’s production lines comprise eight pipe fitting lines and five flange production lines, enabling efficient and large-scale production. Additionally, the company has invested in spectral analysis and a comprehensive physical and chemical testing system, including non-destructive testing, heat treatment, and hydrostatic testing, to ensure the highest standards of product quality and performance.

- Certifications: YANHAO Company holds important certifications, including ISO9001:2000 quality management system certification and pressure piping component manufacturing licenses. These certifications validate the company’s adherence to strict quality standards, manufacturing processes, and regulatory requirements. They serve as a testament to YANHAO’s commitment to delivering reliable and compliant flange products.

With its dedication to quality, competitive pricing, strong supply chain advantages, customization capabilities, advanced equipment, and recognized certifications, YANHAO Company stands as a reputable and reliable flange processing manufacturer in the industry. The company’s commitment to customer satisfaction and its ability to meet diverse customer needs make it a preferred choice for flange solutions on a global scale.

Global Marketing and Market Opportunities

Advantages and Opportunities of Promoting YANHAO’s Products in the Global Market:

- Expertise in Flange Manufacturing: YANHAO Company possesses extensive expertise and experience in flange manufacturing. With eight pipe-fitting production lines and five flange production lines, the company has demonstrated its capability to deliver high-quality flange products that meet international standards. This expertise positions YANHAO as a reliable and knowledgeable provider of flange solutions.

- Authority in the Industry: YANHAO’s location in Hebei, known as the “Flange Hometown” of China, grants the company a strong industry authority. Hebei is recognized as a major flange production base, enabling YANHAO to tap into a wealth of knowledge and resources. This authority enhances the company’s credibility and reputation, making it an attractive choice for global customers seeking reliable and reputable flange manufacturers.

- Trustworthiness and Quality Assurance: YANHAO prioritizes quality management and has established a comprehensive quality control system. The company holds ISO9001:2000 certification, demonstrating its commitment to consistently delivering high-quality products. Additionally, YANHAO’s adherence to pressure piping component manufacturing licenses further ensures compliance with regulatory requirements. This commitment to quality and trustworthiness instills confidence in customers, making YANHAO a trusted partner in the global market.

- Competitive Pricing: YANHAO’s location in China, with its inherent cost advantages in manufacturing, allows the company to offer competitive pricing. The combination of high-quality products and cost-effectiveness enhances YANHAO’s attractiveness in the global market. Customers can expect superior flange solutions without compromising their budget.

- Customization Capabilities: YANHAO’s ability to provide customized flange solutions is a significant advantage in the global market. By offering tailored non-standard flange fittings and accommodating large-sized flange requirements, the company can cater to the specific needs of diverse industries and projects. This flexibility positions YANHAO as a preferred choice for customers seeking customized flange solutions.

- Market Opportunities: The global demand for flange fittings continues to grow with increasing infrastructure development, construction projects, and industrial applications. YANHAO can capitalize on these market opportunities by promoting its high-quality products, competitive pricing, customization capabilities, and expertise in the global market. By targeting industries such as oil and gas, petrochemical, power generation, and construction, YANHAO can expand its customer base and seize new business opportunities.

Overall, YANHAO Company possesses the expertise, authority, and trustworthiness necessary to succeed in the global market. By highlighting its industry knowledge, commitment to quality, competitive pricing, customization capabilities, and capitalizing on market opportunities, YANHAO can establish itself as a reliable and preferred provider of flange solutions worldwide.

Conclusion

In conclusion, ANSI and ASME flanges are two commonly used types of flange fittings with distinct differences and application areas. ANSI flanges adhere to the standards set by the American National Standards Institute and are widely used in the United States, while ASME flanges conform to the specifications established by the American Society of Mechanical Engineers and are recognized globally.

ANSI flanges are primarily used in low-pressure and non-critical applications, such as plumbing systems, general industrial piping, and residential projects. They come in various classes and face types to accommodate different pressure ratings and sealing requirements.

On the other hand, ASME flanges are designed for high-pressure and high-temperature applications in industries such as oil and gas, petrochemical, power generation, and process industries. They are available in specific pressure classes, and their dimensions and tolerances are more precisely defined to ensure robustness and reliability under extreme conditions.

As a flange processing manufacturer, YANHAO has several competitive advantages that reinforce its position in the market. The company’s commitment to superior quality, competitive pricing, and extensive customization capabilities set it apart. YANHAO leverages its strategic location in Hebei, China, the heart of the flange industry, benefiting from a strong supply chain and access to high-quality raw materials. The company’s advanced equipment and certifications, such as ISO9001:2000 and pressure piping component manufacturing licenses, further validate its expertise, authority, and commitment to delivering reliable and compliant flange products.

With its comprehensive range of flange solutions, including ANSI and ASME flanges, YANHAO is well-positioned to serve a wide range of industries and applications globally. Whether it is for low-pressure plumbing systems or high-pressure industrial projects, customers can rely on YANHAO for high-quality flange fittings that meet their specific requirements. The company’s dedication to customer satisfaction, continuous improvement, and its ability to adapt to market demands further strengthen its position as a trusted and preferred flange processing manufacturer.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.