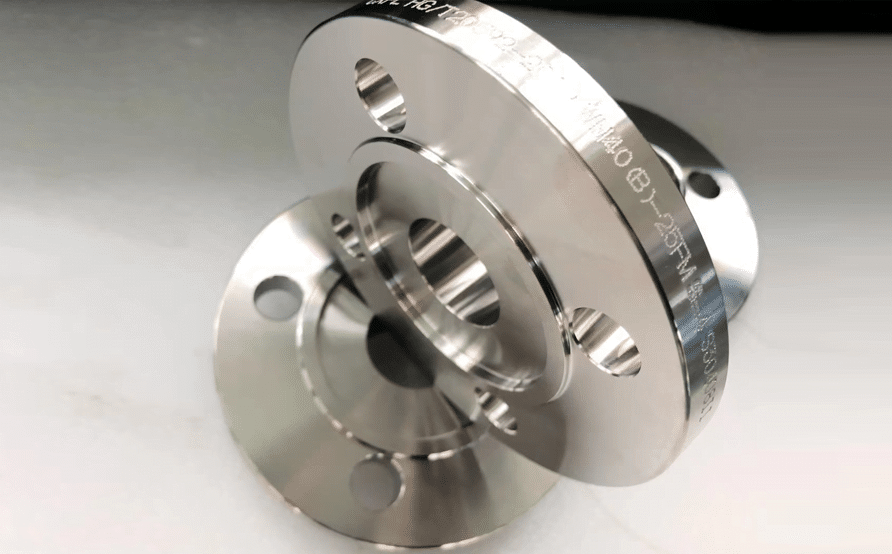

ASME/ANSI B16.5 Flanges

Our company provides ASME/ANSI B16.5 Flanges.

ASME B16.5 standard covers Steel Pipe Flanges and Flanged Fittings from NPS 1/2 through NPS 24 Metric/Inch in pressure class 150 to class 2500.

lewis Liu

sales Manager

ASME/ANSI B16.5 Flanges

ASME/ANSI B16.5 is a standard jointly developed by the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) for the design, sizing, manufacturing, and testing requirements of flanges and flange connections in piping systems. NPS covering pressure levels 150 to 2500 ½” To NPS 24 “steel pipe flanges and flange fittings. This includes pressure rating, dimensions, tolerances, materials, markings, and testing. It is also known as ASME B16.5 or ANSI B16.5.

Here is a table outlining the specifications and characteristics of ASME/ANSI B16.5 Flanges:

| Specification/Feature | Description |

|---|---|

| Standard | ASME/ANSI B16.5 Flanges. |

| Types | Weld Neck Flange, Slip-On Flange, Threaded Flange, Socket Weld Flange, Blind Flange, and Lap Joint Flange. |

| Pressure Ratings | Class150, Class300, Class600, Class900, Class1500, Class2500, etc. |

| Size Range | From 1/2 inches to 48 inches or larger |

| Materials | carbon steel, stainless steel, alloy steel, and more, chosen based on application requirements. |

| Facing Types | Raised Face (RF), Flat Face (FF), Ring-Type Joint (RTJ), and Male and Female (M&F) facings. |

| Bolt Hole Quantity and Diameter | The number and diameter of bolt holes vary with flange size and pressure rating. |

| Connection Method | typically connected using bolts and nuts |

| Seal Types | commonly employ gaskets or O-rings for sealing |

| Accessories and Attachments | flange gaskets, bolts, nuts, flange covers, or flange cover gaskets. |

| Inspection and Testing | Dimensional inspection, surface quality inspection, chemical composition analysis, mechanical performance testing, leakage testing, corrosion resistance testing, coating inspection, ultrasonic testing, magnetic particle testing, etc. |

| Marking and Certification | The flange will be marked with the ASME/ANSI B16.5 standard number, as well as size, material, pressure rating, and manufacturer identification. There are also some certification marks such as ASME certification and API certification. |

| Application Areas | These flanges are widely used in industries such as oil and gas, petrochemical, water treatment, and more for connecting pipes, valves, pumps, and equipment. |

This table provides a comprehensive overview of ASME/ANSI B16.5 Flanges, covering key specifications, characteristics, and additional considerations. Specific details and requirements may vary based on the chosen flange type, size, pressure rating, and material.

Installation of ASME/ANSI B16.5 flanges

- Preparation work:

- Prepare the flanges, accessories, and installation tools that need to be connected. Before installation, inspect the flanges to ensure that the model and size are correct and undamaged, and ensure clean performance.

- Installing flanges

- -Fix the flange and pipeline positions in preparation for installation.

- -Correct installation and matching of gasket material and size with flange.

- -Ensure that the connection surface is aligned with the bolt holes, use bolts that are sturdy and not too tight, leaving some room for adjustment.

- -After checking to ensure that the connection is correct, tighten the bolts one by one to ensure that the required tightening force is achieved, to ensure that there is no leakage.

- Check flange connections

- After the flange connection is completed, the pipeline and flange should be checked for alignment, all bolts should be firm, and the pipeline and flange should be checked for alignment and compliance with construction requirements.

- Leakage testing

- Conduct corresponding gas or liquid leakage tests according to project requirements.

- Clean up the site

- Organize the installation tools for future use, and clean up the on-site garbage to ensure a clean and tidy environment.

- Record Information

- Make detailed records of the installed flanges for later inspection and maintenance.

Routine maintenance and upkeep of ASME/ANSI B16.5 flanges

- Regular inspections

- Regular inspections should ensure that the surface of the flange connection is clean and free of debris, especially corrosive substances. If necessary, it should be cleaned in a timely manner.

- At the same time, it is necessary to regularly inspect the flange surface, connections, and around bolt holes for signs of corrosion, damage, or leakage. If there are any, they must be repaired or replaced in a timely manner.

- Regularly conduct ultrasonic testing, magnetic particle testing, etc. on the flange connection parts, and promptly repair or replace any problems found.

- Regular maintenance

- Regular tightening checks should be carried out on the flange connection parts, especially the bolts. If any looseness is found, it should be tightened or replaced immediately. At the same time, lubricant should be applied regularly to avoid rusting of the bolts

- The flange gasket should also be regularly inspected for damage and replaced regularly according to the specified time to ensure a good seal without leakage.

- Anti-corrosion treatment

- For flanges in corrosive environments, it is necessary to regularly apply anti-corrosion paint and use anti-corrosion gaskets to prevent leakage caused by corrosion.

- Record maintenance information

- To use the maintenance registration form to record maintenance information for smooth subsequent work.