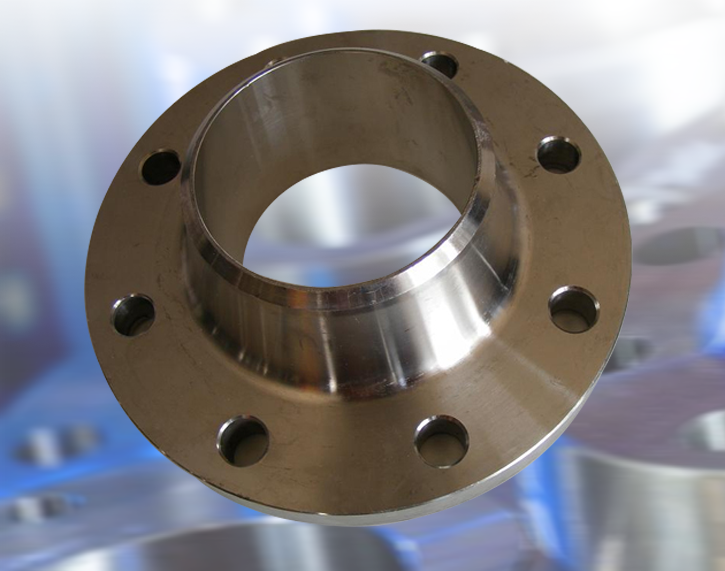

Weld Neck Flanges

Our company provides Weld Neck Flanges.

We provide flange products of various standards such as American standards, European standards, German standards, and Japanese standards. The list of common standards is as follows:

lewis Liu

sales Manager

Weld Neck Flanges

Weld neck flange has a long neck in the middle for butt welding with pipes. So it is also called high neck flange or long neck flange. Often used in high temperature and high pressure and pipe diameter is relatively large pipeline.

Weld neck flange is commonly standardized as ASME B16.5 and ASME B16.47, with sizes ranging from 1/2-inch to 60-inch, and sealing surface types including raised face (RF), flat face (FF), dimpled face (MFM), tongue and groove (TG), ring joint (RJ), and so on. Applicable pressure classes include Class150, 300, 400, 600, 900, 1500, 2500 and other 7 classes. Common materials include stainless steel F304/304L, F316/316L, F321, F347, F904L, F51, F53, F55 and so on.

Here is a table outlining the specifications and characteristics of Weld Neck Flanges:

| Specification/Feature | Description |

|---|---|

| Appearance | Weld Neck Flange is disk-shaped, in which there is a raised neck called flange neck, flange neck around a number of bolt holes. |

| Pressure Ratings | class15(PN16), class300(PN25),class600(PN50), class900(PN64), class1500(PN260), class2500(PN420). |

| Size Range | Typically available in sizes ranging from 1/2 inches to 48 inches or larger, suitable for various pipe and equipment sizes. |

| Materials | Weld Neck Flanges can be manufactured from materials like carbon steel, stainless steel, alloy steel, and more, chosen based on application requirements. |

| Facing Types | Common facing types include Raised Face (RF), Flat Face (FF), Ring-Type Joint (RTJ), and Male and Female (M&F) facings, impacting sealing methods. |

| Bolt Hole Quantity and Diameter | The number and diameter of bolt holes vary with flange size and pressure rating, facilitating flange connection. |

| Connection Method | Weld Neck Flanges are butt-welded to the pipe, providing a strong and leak-resistant connection. |

| Application Areas | Weld Neck Flanges are widely used in industries such as oil and gas, petrochemical, power generation, and more for connecting high-pressure piping systems. |

| Standards and Codes | Weld Neck Flanges adhere to standards set by the American National Standards Institute (ANSI) and nominal pipe size (NPS) standards, such as ANSI B16.5. |

| Seal Types | Weld Neck Flanges commonly use gaskets or O-rings for sealing, with the choice of seal type depending on the application and pressure rating. |

| Accessories and Attachments | Some applications may require additional components such as flange gaskets, bolts, nuts, flange covers, or flange cover gaskets. |

| Inspection and Testing | Weld Neck Flanges typically undergo a series of inspections and tests to ensure they meet quality and performance requirements, in compliance with standards. |

| Marking and Certification | Weld Neck Flanges should be marked with the manufacturer’s identification, size, class, material, and other relevant information. Some flanges may require specific certifications such as PED or ASME. |

| Installation and Maintenance | Proper installation and regular maintenance of Weld Neck Flanges, including weld integrity, bolt torque, flange face cleaning, and seal replacement, are crucial for system integrity and performance. |

| Application Standards | In specific industries and applications, there may be industry-specific Weld Neck Flange application standards that need to be adhered to for safety and performance. |

This table provides a comprehensive overview of Weld Neck Flanges, covering key specifications, characteristics, and additional considerations. Specific details and requirements may vary based on the chosen flange size, pressure rating, and material.