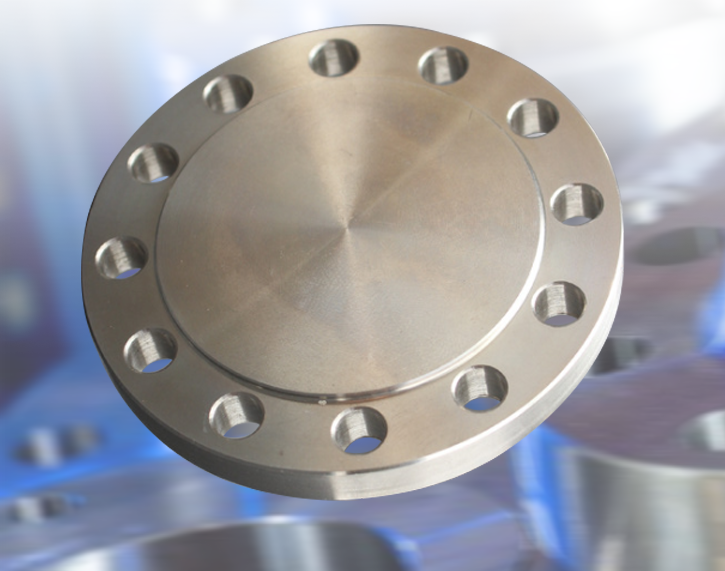

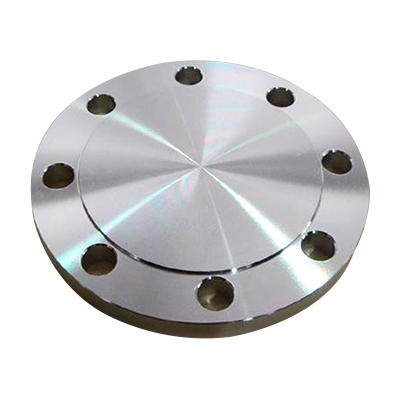

Blind Flanges

Our company provides Blind Flanges.

The blind flange is a flange used at the end of the pipeline and mainly plays a closed role, it is also called a flange cover or plug.

Blind Flanges

The blind flange is also known as the flange cover, the reason is that it is different from other flanges, the center is closed, like a cover, to seal the pipeline, so it is also known as a plug, mainly used for the pipeline ending, or needs to temporarily close the place of maintenance.

Here is a table outlining the specifications and characteristics of Blind Flanges:

| Specification/Feature | Description |

|---|---|

| Pressure Ratings | class150, class300, class600, class900, class1500, class2500 |

| Size Range | 1/2″-60″ |

| Materials | carbon steel, stainless steel, alloy steel |

| Facing Types | Raised Face (RF), Flat Face (FF), Ring-Type Joint (RTJ), and Male and Female (M&F) |

| Bolt Hole Quantity and Diameter | The number and diameter of bolt holes vary with flange size and pressure rating |

| Connection Method | Blind flanges can be connected by bolting, welding, flanging, quick clamping, or quick swivel connection. |

| Standards and Codes | ASME/ANSI B16.5,ASME/ANSI16.47 |

| Seal Types | O-rings are usually used for sealing, as well as flat seals, seals with flanges and grooves that fit into each other, seals with packing or sealant between threads, and seals by welding. |

| Accessories and Attachments | Common fittings and accessories are seals, sealing gaskets, bolts and nuts. |

| Inspection and Testing | Common fittings and accessories are seals, sealing gaskets, bolts, and nuts. |

| Marking | It mainly includes size inspection, appearance inspection, material inspection, sealing performance test, pressure resistance test, connection strength test, wear and tear test, and so on. |

| Certification | Common certifications include ISO, ASME, API, etc. Certification indicates that the flange meets the requirements of standard specifications. |