I. Introduction

Welcome to our blog, “Behind the Scenes: Exploring the Secrets of China Flange Factory.” In this insightful journey, we invite you to uncover the hidden world of China’s flange manufacturer and discover the exceptional craftsmanship of YANHAO (盐浩), a prominent flange manufacturer based in Cangzhou, Hebei, China.

Flanges play a vital role in various industries, providing a crucial connection between pipes, valves, and equipment. As the demand for high-quality flange products continues to rise, YANHAO stands at the forefront, delivering excellence and precision in every piece they produce.

In this blog, we will delve into the intricate processes, advanced technologies, and unwavering commitment to quality that define YANHAO’s operations. From the careful selection of top-grade materials to the utilization of state-of-the-art machinery, YANHAO’s expertise shines through at every stage of the manufacturing process.

Not only does YANHAO possess an impressive array of product lines and a massive annual output capacity, but they also excel in customizing non-standard flange products. Their ability to meet diverse client requirements, even for large-sized flanges, sets them apart in the industry.

Beyond its manufacturing prowess, YANHAO takes pride in its comprehensive quality control measures and testing protocols. Their adherence to international standards, including ISO9001:2000 certification and pressure component manufacturing license, ensures that each flange leaving their facility is of superior quality and reliability.

Moreover, YANHAO’s commitment to continuous improvement and innovation is evident through their investment in research and development, as well as collaborations with global partners. These endeavors allow them to stay at the forefront of technological advancements in the flange industry and cater to the evolving needs of their customers worldwide.

Situated in Cangzhou, known as the hub of flange production in China, YANHAO benefits from a robust supply chain and easy access to premium raw materials. This advantage, combined with their efficient operations and customer-centric approach, enables them to deliver outstanding products and exceptional service to clients across the globe.

At YANHAO, the pursuit of quality, expertise, and customer satisfaction is deeply ingrained in their philosophy. Their unwavering commitment to maintaining the highest standards of craftsmanship has earned them a reputation as a trusted and reliable flange manufacturer.

Join us as we unveil the secrets behind China’s flange manufacturing industry and discover the remarkable story of YANHAO, an industry leader committed to excellence and innovation. Let us embark on this enlightening journey into the heart of flange production, where precision meets reliability and expertise meets trust.

Let the exploration begin.

II. The Flange Manufacturing Process

A. Raw Material Selection and Inspection

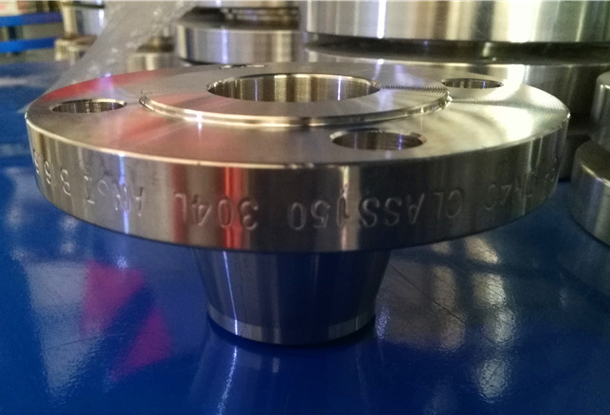

At YANHAO, the process of manufacturing flanges starts with meticulous raw material selection. The company upholds stringent standards when it comes to choosing high-quality stainless steel, alloy steel, and carbon steel. These materials are crucial for ensuring the durability, strength, and performance of the final flange products.

YANHAO’s expert team carefully sources materials from reputable suppliers known for their adherence to international quality standards. They prioritize materials with exceptional corrosion resistance, mechanical properties, and overall structural integrity. Factors such as composition, grain size, and microstructure are meticulously evaluated to guarantee the suitability of the raw materials for flange production.

To ensure the integrity and reliability of the flange products, YANHAO places great importance on thorough material inspection. A comprehensive inspection process is carried out to identify any defects, inconsistencies, or deviations that could compromise the performance and quality of the final products.

Advanced testing methods, such as spectroscopy, ultrasonic testing, and hardness testing, are employed to assess the material’s properties. These tests provide valuable insights into the chemical composition, internal soundness, and mechanical characteristics of the raw materials.

By conducting rigorous material inspections, YANHAO mitigates the risks of using substandard or flawed materials in the manufacturing process. This commitment to quality control ensures that only materials meeting the highest standards are utilized, thereby guaranteeing the exceptional quality and performance of the flanges produced.

Through meticulous raw material selection and comprehensive inspection procedures, YANHAO sets the foundation for manufacturing flanges of superior quality, durability, and reliability. These critical steps in the production process reflect the company’s unwavering commitment to delivering products that meet and exceed customer expectations.

B. Precision Machining Techniques

YANHAO employs state-of-the-art machinery and equipment to ensure precision and accuracy throughout the flange manufacturing process. Advanced technologies and innovative tools enable the company to achieve high-quality results and meet the diverse requirements of customers.

The company’s production facilities are equipped with cutting-edge CNC (Computer Numerical Control) machines that offer exceptional precision and repeatability. These machines utilize computer-aided design (CAD) and computer-aided manufacturing (CAM) software to precisely shape and machine the raw materials into flange components. CNC turning centers, milling machines, and drilling machines are among the key equipment utilized for precise machining operations.

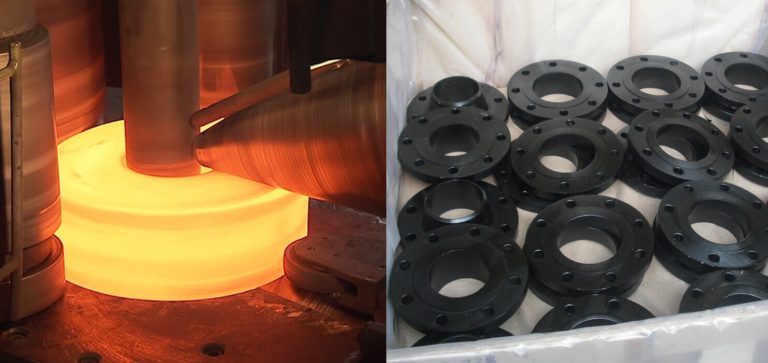

YANHAO employs various machining processes to shape and form flange components with utmost precision. These processes include hydraulic pressing and bending, which are crucial for achieving the desired shape, dimensions, and functionality of the flanges.

Hydraulic pressing involves the use of specialized hydraulic presses to apply controlled force on the raw materials. This process allows for the precise forming of the flange components, ensuring accurate dimensions and maintaining the structural integrity of the material.

Bending is another important machining process utilized by YANHAO. Through the use of hydraulic bending machines, the raw materials are carefully shaped into the required curvature and angle, meeting specific design and application requirements. This process ensures that the flanges have the necessary geometric properties to facilitate proper alignment and connection in various piping systems.

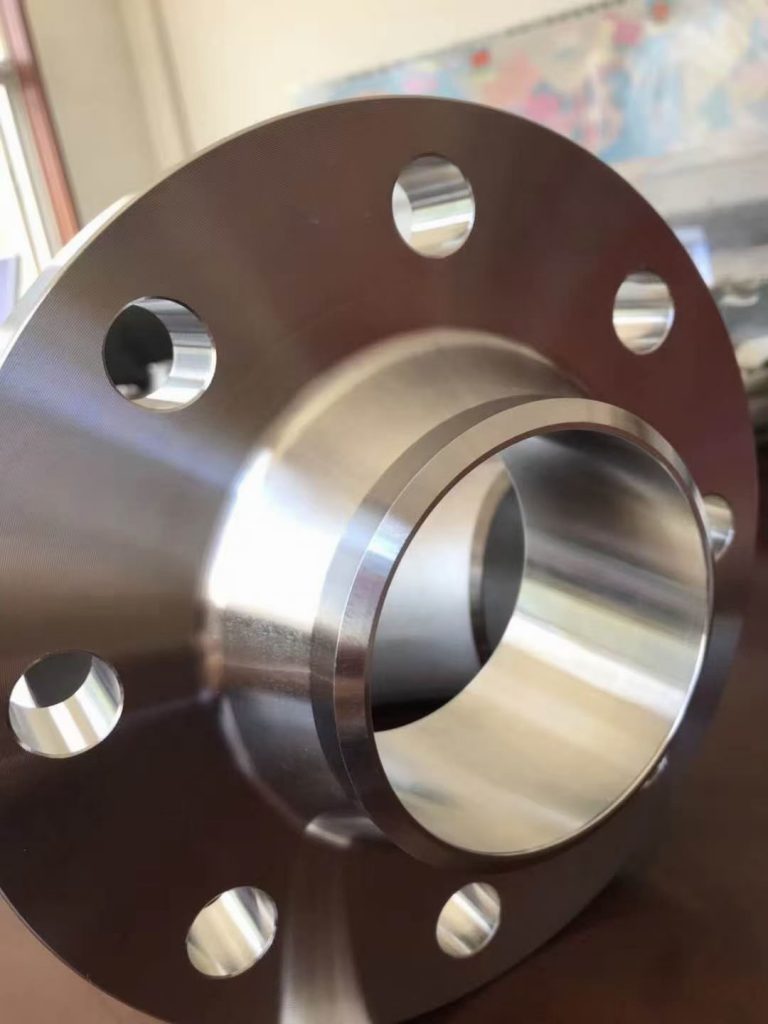

One of YANHAO’s notable strengths is its ability to customize non-standard flange products according to customers’ unique specifications. The company understands that different industries and applications require flanges with specific dimensions, materials, and configurations.

YANHAO’s highly skilled engineers and technicians work closely with customers to understand their exact requirements. Leveraging their expertise and utilizing advanced machining techniques, they are able to develop and manufacture non-standard flanges that meet even the most challenging demands.

With access to cutting-edge equipment, including large-capacity hydraulic presses, bending machines, and precision machining tools, YANHAO can produce flanges in various sizes, shapes, and materials. This capability allows the company to serve a wide range of industries and applications, offering tailored solutions that perfectly match customers’ needs.

By combining advanced machining techniques with the flexibility to produce non-standard flange products, YANHAO demonstrates its commitment to delivering high-quality, customized solutions. This expertise positions the company as a trusted partner for customers seeking precision, reliability, and adaptability in their flange requirements.

C. Quality Control and Testing

At YANHAO, ensuring the highest quality standards is a top priority throughout the flange manufacturing process. The company has implemented rigorous quality control measures to guarantee that every product meets or exceeds customer expectations.

YANHAO follows a comprehensive quality management system that encompasses all stages of production. From raw material procurement to the final inspection of finished products, each step is meticulously monitored to maintain consistent quality. The company has established strict procedures and protocols to minimize variations and defects, ensuring reliable and durable flange products.

YANHAO employs a range of testing methods to verify the quality and performance of its flange products. These testing methods include:

- Physical and chemical analysis: YANHAO conducts thorough physical and chemical analyses to verify the composition, mechanical properties, and corrosion resistance of the materials used in flange production. This analysis ensures that the selected stainless steel, alloy steel, and carbon steel meet the required specifications and standards.

- Non-destructive testing: YANHAO utilizes non-destructive testing techniques, such as ultrasonic testing and X-ray inspection, to detect any internal or surface defects that may compromise the integrity of the flanges. These tests ensure that the products are free from flaws and meet the highest quality standards.

- Dimensional inspection: Precise dimensional measurements are carried out to verify that the flange components adhere to the specified dimensions and tolerances. This ensures proper fit and compatibility during installation and use.

- Pressure testing: YANHAO conducts pressure testing to evaluate the strength and integrity of flanges under varying operating conditions. This testing ensures that the flanges can withstand the required pressures without leakage or failure.

YANHAO places great importance on compliance with international standards and certifications. The company has obtained the ISO9001:2000 certification, which demonstrates its commitment to maintaining a robust quality management system and continuously improving its processes.

Additionally, YANHAO holds the pressure component manufacturing license, affirming its adherence to the stringent regulations and requirements governing the production of pressure components.

By complying with these international standards and certifications, YANHAO ensures that its flange products meet the highest levels of quality, reliability, and safety. Customers can have confidence in the performance and longevity of YANHAO’s flanges, knowing they have undergone rigorous testing and conform to industry-recognized standards.

III. Technological Expertise and Innovation

A. Research and Development (R&D) Efforts

YANHAO is dedicated to continuous improvement and innovation in the flange manufacturing industry. Recognizing the importance of staying ahead in a competitive market, the company invests significant resources in research and development (R&D) to enhance its products and processes.

YANHAO’s commitment to innovation is driven by its desire to provide customers with cutting-edge solutions that meet their evolving needs. By staying abreast of industry trends and technological advancements, YANHAO continually explores new techniques, materials, and design concepts to optimize the performance, efficiency, and reliability of its flange products.

YANHAO recognizes that innovation requires a strong foundation of expertise and resources. To support its R&D efforts, the company has established state-of-the-art facilities equipped with advanced machinery, precision tools, and testing equipment. These facilities enable YANHAO’s engineers and researchers to conduct in-depth studies, develop prototypes, and perform rigorous testing.

YANHAO also values the importance of skilled engineers in driving innovation. The company employs a team of experienced and highly qualified engineers who specialize in flange manufacturing. These engineers possess a deep understanding of materials, machining techniques, and industry standards. Their expertise enables YANHAO to explore new possibilities, develop novel solutions, and continually improve its products.

By investing in R&D facilities and nurturing a team of skilled engineers, YANHAO demonstrates its commitment to technical expertise and innovation. The company’s continuous pursuit of advancement ensures that it remains at the forefront of the flange manufacturing industry, delivering innovative products that meet the ever-changing demands of its global customer base.

B. Collaboration with Global Partners

YANHAO values collaboration and recognizes the importance of building strong partnerships with clients and industry experts worldwide. Through its commitment to forging global connections, YANHAO has established fruitful collaborations with esteemed international clients and partners.

These collaborations span various sectors and geographies, enabling YANHAO to gain valuable insights into global market trends, customer preferences, and industry best practices. By working closely with international clients, YANHAO has developed a deep understanding of their specific requirements and has been able to tailor its flange products to meet their diverse needs.

YANHAO’s collaborations with global partners play a pivotal role in driving its technological advancements. By engaging in knowledge-sharing and collaborative projects, YANHAO gains access to a wealth of expertise, diverse perspectives, and innovative ideas from around the world.

Through joint research initiatives and information exchange, YANHAO remains at the forefront of technological developments in the flange manufacturing industry. It leverages the insights and experiences of its global partners to enhance its production processes, refine product designs, and incorporate the latest technological advancements into its offerings.

Furthermore, these collaborations foster a culture of innovation within YANHAO. By actively engaging with global partners, the company encourages creativity, stimulates new ideas, and fosters a spirit of continuous improvement. The exchange of knowledge and expertise contributes to YANHAO’s ability to deliver high-quality, technologically advanced flange products to its customers.

In summary, YANHAO’s collaborations with international clients and partners are instrumental in driving its technological advancements. These partnerships enable the company to tap into a global network of expertise, stay ahead of industry trends, and deliver innovative solutions that exceed customer expectations. By fostering collaborative relationships, YANHAO solidifies its position as a leading player in the flange manufacturing industry.

IV. Supply Chain Advantage

A. Location Advantage in Cangzhou, Hebei, China

Located in Cangzhou, Hebei, China, YANHAO benefits greatly from its strategic location in the heart of one of China’s most prominent industrial regions. Cangzhou has earned a well-deserved reputation as the hub of flange production in China, making it an ideal base for YANHAO’s operations.

Cangzhou’s rich industrial heritage and extensive infrastructure have attracted numerous flange manufacturers, forging a concentrated cluster of industry expertise. The region boasts a wealth of specialized knowledge, skilled labor, and established manufacturing practices specific to flange production. This concentration of expertise fosters a competitive environment that drives innovation and continuous improvement.

Operating in Cangzhou provides YANHAO with a distinct advantage in terms of its supply chain and raw material sources. The region is strategically positioned to tap into a robust network of suppliers, ensuring a steady and reliable flow of raw materials for flange production.

Cangzhou’s proximity to major steel mills and metal suppliers enables YANHAO to source high-quality stainless steel, alloy steel, and carbon steel materials with ease. This proximity not only reduces transportation costs but also facilitates close collaboration with suppliers to ensure strict adherence to quality standards and timely delivery.

Furthermore, being in close proximity to raw material sources allows YANHAO to have greater control and visibility over the entire supply chain. The company can actively monitor the quality of raw materials, conduct thorough inspections, and implement stringent quality control measures right from the initial stages of production. This ensures that YANHAO consistently delivers flange products of the highest quality and integrity.

In summary, YANHAO’s location in Cangzhou, Hebei, China provides significant advantages in terms of access to a well-established supply chain and abundant raw material sources. The region’s reputation as the hub of flange production, combined with its robust infrastructure and specialized expertise, enables YANHAO to operate efficiently, maintain strict quality control, and deliver exceptional flange products to its customers.

B. Manufacturing Capacity and Efficient Operations

YANHAO takes pride in its robust manufacturing capacity, which enables the company to meet the diverse needs of its customers. With state-of-the-art facilities and advanced equipment, YANHAO maintains efficient production processes that ensure both quality and quantity.

The company operates eight pipe-fitting production lines and five flange production lines, showcasing its scale and ability to handle large volumes of production. These production lines are equipped with cutting-edge machinery and specialized tools, allowing for precise and accurate manufacturing.

Annually, YANHAO has an impressive production capacity exceeding 80,000 tons. This high output demonstrates the company’s commitment to meeting the demands of the market while maintaining the highest standards of quality control.

Efficiency is at the core of YANHAO’s operations. To meet customer demands effectively, the company has implemented streamlined management systems and processes that optimize productivity and ensure timely delivery.

YANHAO utilizes advanced production planning and scheduling software to manage its operations efficiently. This allows for effective coordination of resources, minimizing production bottlenecks, and optimizing workflow. By closely monitoring production timelines and capacities, YANHAO can ensure on-time delivery, providing customers with reliable and prompt service.

Moreover, YANHAO’s production processes are guided by lean manufacturing principles. The company continuously seeks opportunities for process improvement, eliminating waste, and optimizing production flow. This commitment to lean practices enhances operational efficiency, reduces lead times, and increases overall productivity.

YANHAO also maintains a strong focus on quality management systems. The company adheres to international standards, such as ISO9001:2000, ensuring that every step of the production process meets stringent quality requirements. Through rigorous inspections, testing, and quality control measures, YANHAO upholds its commitment to delivering flange products of the highest quality.

In summary, YANHAO’s manufacturing capacity and efficient operations set the foundation for its success. With a high production capacity and cutting-edge equipment, the company can meet the demands of the market. By implementing efficient management systems, lean practices, and stringent quality control measures, YANHAO ensures that customer demands are met with precision, timeliness, and superior quality.

V. Commitment to Quality and Customer Satisfaction

A. Quality Assurance Certifications

YANHAO understands the paramount importance of quality assurance in the flange manufacturing industry. The company’s unwavering commitment to delivering superior products is exemplified by its attainment of various certifications that validate its adherence to international quality standards. These certifications not only demonstrate YANHAO’s dedication to excellence but also provide customers with the assurance of product reliability and performance.

YANHAO proudly holds the prestigious ISO9001:2000 certification for its quality management system. This globally recognized certification serves as a testament to the company’s commitment to continuous improvement and customer satisfaction. By strictly adhering to the ISO9001:2000 guidelines, YANHAO ensures that every aspect of its operations, from raw material selection to final product inspection, meets the highest quality standards.

In addition to ISO9001:2000, YANHAO also possesses a pressure component manufacturing license. This license serves as a regulatory affirmation of the company’s ability to manufacture flange products that comply with industry-specific safety and performance standards. It reflects YANHAO’s dedication to producing reliable and durable flanges that meet or exceed customer expectations.

These certifications hold immense significance in guaranteeing product quality and building customer trust. ISO9001:2000 certification signifies that YANHAO has implemented a comprehensive quality management system that encompasses every stage of the manufacturing process. This systematic approach ensures consistency, reliability, and traceability, thereby minimizing the risk of defects or substandard products. Customers can have confidence in YANHAO’s ability to consistently deliver flange products that meet their specifications and perform as intended.

The pressure component manufacturing license further reinforces YANHAO’s commitment to safety and compliance. It assures customers that the company adheres to strict regulations and standards governing the production of pressure components, ensuring that the flanges manufactured by YANHAO are designed and manufactured to withstand the required pressure levels and environmental conditions.

By holding these certifications, YANHAO demonstrates its dedication to quality control, continuous improvement, and customer satisfaction. These certifications not only provide customers with the assurance of product reliability but also instill confidence in the company’s ability to consistently deliver high-quality flange products. YANHAO’s focus on quality assurance and its attainment of these certifications serve as a testament to its commitment to exceeding customer expectations and establishing long-term partnerships based on trust and satisfaction.

B. Customer-Centric Approach

At YANHAO, we prioritize our customers and strive to exceed their expectations in every aspect of our business. Our customer-centric approach is deeply ingrained in our company culture and is reflected in our unwavering commitment to meeting customer requirements and specifications. We understand that each customer has unique needs, and we go above and beyond to deliver tailored solutions that address their specific challenges.

We firmly believe that the success of our customers is intertwined with our own success. Therefore, we make it a top priority to understand and fulfill our customers’ requirements and specifications. Our team of experienced professionals works closely with customers to gain a thorough understanding of their project goals, technical specifications, and delivery timelines. We value open communication and collaboration throughout the entire process to ensure that our products meet or exceed customer expectations.

YANHAO’s flexible manufacturing capabilities enable us to offer a wide range of customization options. Whether it’s producing non-standard flange products or accommodating unique design specifications, we have the expertise and resources to meet diverse customer demands. We leverage our state-of-the-art machinery, skilled workforce, and extensive industry knowledge to deliver high-quality, precision-engineered flanges that precisely match our customers’ requirements.

Our customer satisfaction is a testament to the quality of our products and services. We take great pride in the long-standing partnerships we have built with our clients and the positive feedback we receive from them. Through their testimonials and success stories, we can showcase the value we bring to their projects and the impact our flanges have on their operations.

From multinational corporations to small businesses, our customers have entrusted us with their flange needs, and we have consistently delivered exceptional results. By featuring customer testimonials and success stories on our website and marketing materials, we provide concrete examples of how YANHAO has helped clients overcome challenges, improve efficiency, and achieve their goals. These real-life experiences serve as a powerful endorsement of our capabilities and demonstrate the trust and confidence that customers have in YANHAO as their flange manufacturing partner.

At YANHAO, we are dedicated to forging strong, long-term relationships with our customers. Our customer-centric approach ensures that we are responsive to their needs, deliver high-quality products, and provide exceptional support throughout their journey with us. We believe that by putting our customers first, we can create mutual success and become their trusted partner in the flange manufacturing industry.

VI. Conclusion

In summary, YANHAO is a leading flange manufacturer that exemplifies expertise, authority, and trustworthiness. Our commitment to excellence is evident in our stringent raw material selection, precise machining techniques, and robust quality control measures. With internationally recognized certifications and a customer-centric approach, we consistently deliver high-quality products that meet customer specifications.

Through continuous research and development, collaborations with global partners, and our strategic location advantage in Cangzhou, China, we stay at the forefront of technological advancements in the industry. Our state-of-the-art facilities and skilled engineers enable us to offer customized solutions for non-standard flange products.

We take pride in our efficient operations, ensuring optimal production capacity to meet customer demands. Our focus on customer satisfaction is exemplified by our testimonials and success stories.

At YANHAO, we invite you to explore our comprehensive range of flange products and services. Contact us today to experience our professional expertise and reliable solutions. Let us be your trusted partner in the world of flange manufacturing.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.