ASME/ANSI B16.47 Flanges

Our company provides ASME/ANSI B16.47 Flanges.

Manufacturing all kinds of Flanges to standards ASME/ANSI. Size from 26” – 60”, Many years of production history, high quality, and factory price.

ASME B16.47 standard covers in rating Classes 75, 150, 300, 400, 600, and 900.

lewis Liu

sales Manager

ASME/ANSI B16.47 Flanges

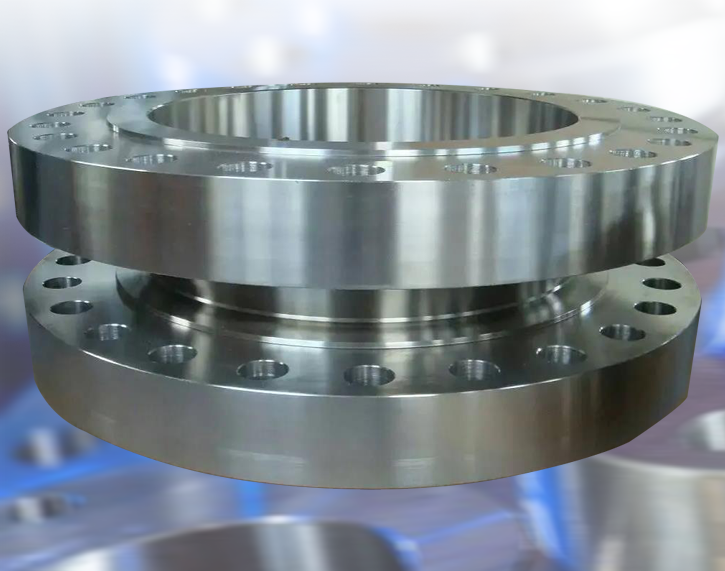

ASME/ANSI B16.47 is a standard for American flanges that specifies the appearance design, dimensions, pressure, manufacturing standards, and testing requirements for large steel butt welded and blind flanges ranging from 26 inches to 60 inches. The main purpose is to improve the versatility of flanges and ensure that flanges manufactured by different flange manufacturers can be used interchangeably in pipelines.

The ASME/ANSI B16.47 flange standard is further divided into two series: ASME/ANSI B16.47 Series A and ASME/ANSI B16.47 Series B.

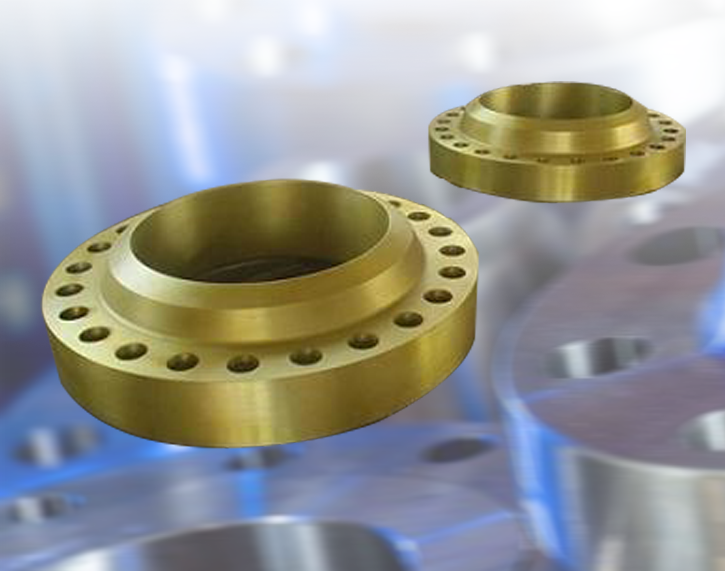

ASME/ANSI B16.47 Series A is mainly used in high-pressure environments such as oil and gas, while compared to ASME/ANSI B16.47 Series B, it is commonly used in low-pressure environments such as water treatment.

| Specification/Feature | Description |

|---|---|

| Standard | ASME/ANSI B16.47 Flanges, including both Series A and Series B sub-standards. |

| Type | Weld Neck Flanges, Blind flanges. |

| Pressure Rating | Class 75, Class 150, Class 300, Class 600, Class 900. |

| Size Range | 26″-60″ |

| Material | carbon steel, stainless steel, alloy steel, etc. |

| Facing Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), Tongue and Groove (T&G), Male and Female (M&F) |

| Seal Type | ASME/ANSI B16.47 Flanges commonly use gaskets or O-rings for sealing. |

| Performance Characteristics | Known for excellent pressure-bearing capacity and sealing performance, suitable for high-pressure, high-temperature, critical applications, etc. |

| Classification | ASME/ANSI B16.47 Series A, ASME/ANSI B16.47 Series B |

| Application Areas | ASME/ANSI B16.47 Flanges find widespread use in industries such as petroleum, natural gas, chemical, nuclear, maritime, etc. |