YANHAO Your Reliable China Flange Manufacturer, Factory & Supplier

YANHAO, with 25 years of expertise, crafts top-tier flanges right here in China. Our premium products guarantee leak-free pipelines, all at unbeatable prices. Choose YANHAO for excellence.

Welcome to YANHAO

Made in China, high-quality flanges, pipes, and fittings at competitive prices.

Welcome to YANHAO, China’s largest and most professional pipeline production base. We specialize in manufacturing high-quality carbon steel flanges, stainless steel flanges, and various pipe fittings. With advanced production equipment and years of experience, we are committed to providing you with the best products and services.

Contact us now for a free sample and quotation!

Our Product Range

At YANHAO, we understand the importance of choosing the right flange for your project. Therefore, we provide a full range of flange products, like weld neck flanges, slip-on flanges, and blind flanges. Our goal is to offer you the highest-quality products to ensure the safety, reliability, and efficiency of your piping systems.

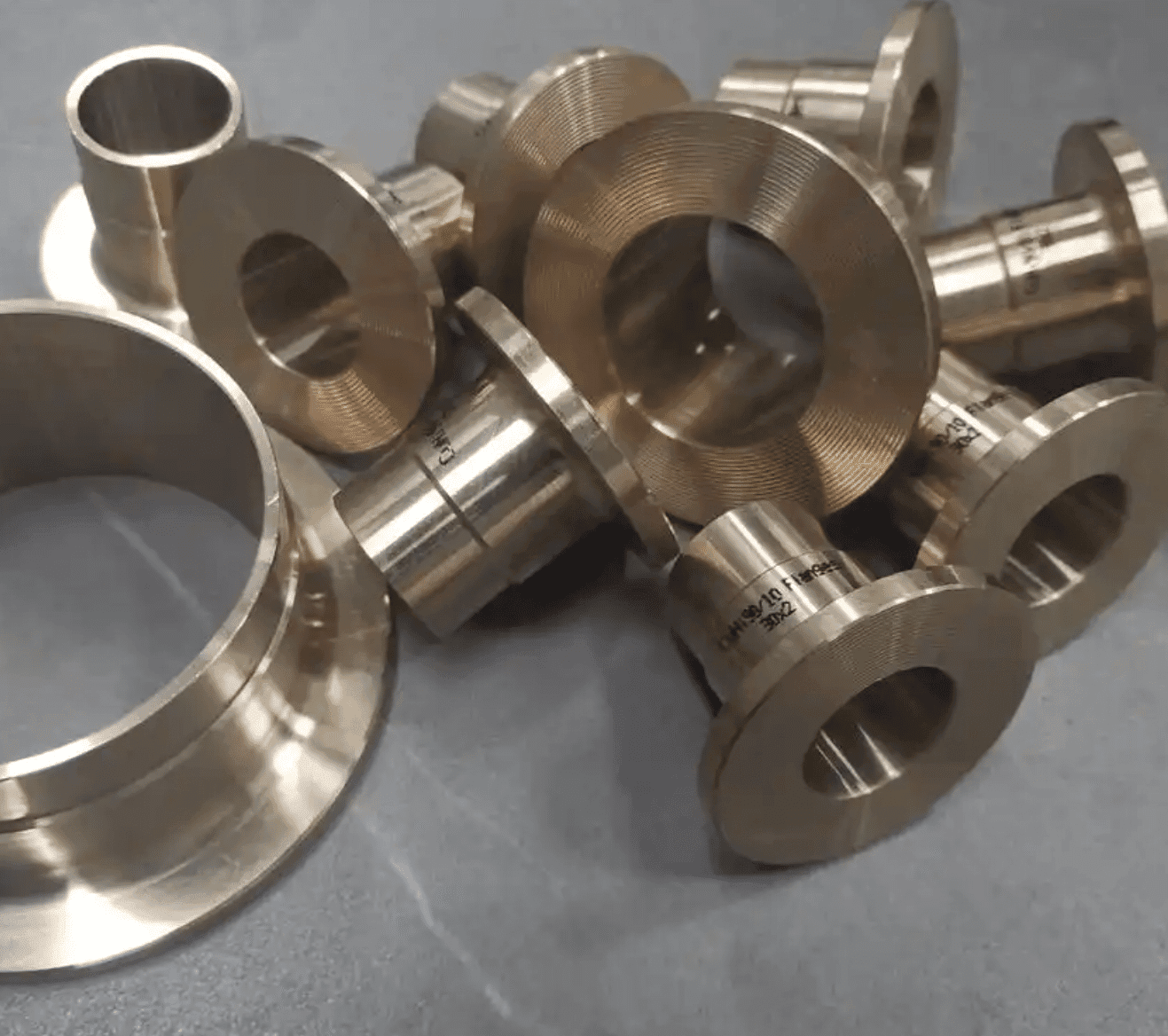

Weld Neck Flanges (WN)

WN flange, also known as a trapped hub flange or high-hub flange, is a high-stress-containing flange. Its circular fitting component, the rim, is fitted around the circumference.

China welding neck flange products >>

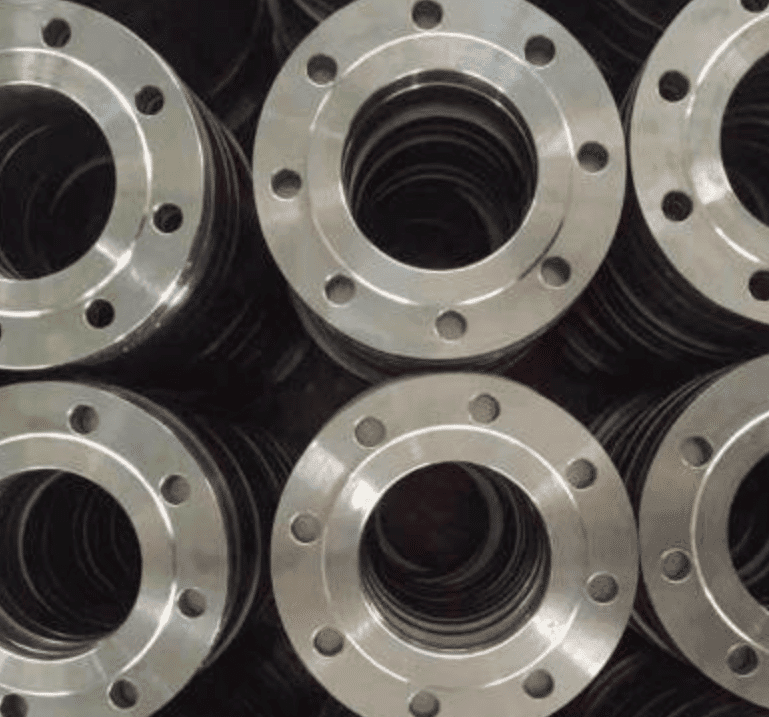

Slip-on Flanges (SO)

Slip-on flanges, as the name shows, can be easily slipped onto the end of a pipe or fitting and then welded in place. It usually has a flat face and a protruding face.

China slip-on flange products >>

Socket Weld Flanges (SW)

Socket Weld Flanges (SW) are similar to Slip-on Flanges (SO). The difference is that there is an extra piece in the middle.

China socket weld flange products >>

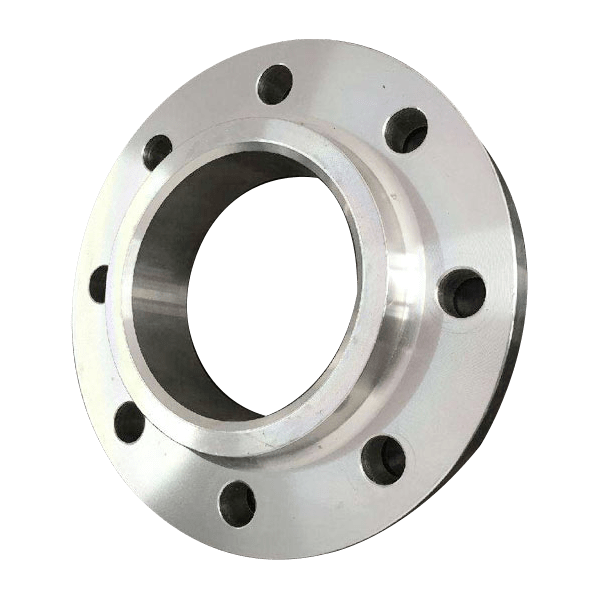

Blind Flanges (BF)

Blind flange is also called flange cover. It is a flat, circular plate used to cover the ends of pipes, valves, or joints.

China blind flange products >>

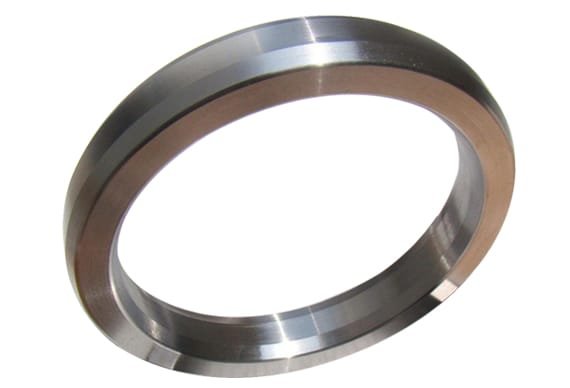

Lap joint flange (LJ)

Consisting of two components: a stub end and a lap joint ring flange. The respective stub end is slid into the flange’s bore, and the stub end is joined to the pipe through butt welding.

China lap joint flange products >>

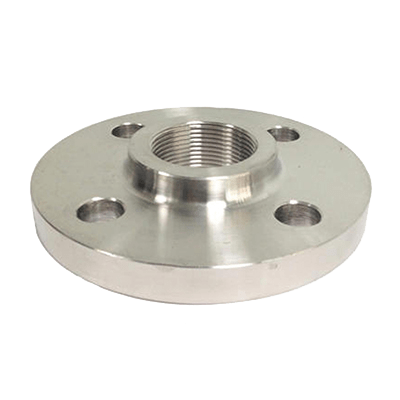

Threaded Flanges (TF)

Threaded flanges are pipe flanges with internal threading to match external threads on a pipe. The installation does not involve welding

China threaded flange products >>

At YANHAO, we understand the importance of choosing the right flange for your project. Therefore, we provide various materials of flanges, such as carbon steel, alloy steel, stainless steel, etc.

Why Choose YANHAO?

Unbeatable price, quality, innovation, and customer satisfaction.

With over 25 years of industry experience, we bring unparalleled expertise to every project. Our state-of-the-art manufacturing facilities and rigorous quality control processes ensure that each flange we produce meets the highest international standards.

We offer competitive pricing without compromising on quality, making YANHAO not just a reliable but also a cost-effective solution for all your flange needs. Choose YANHAO for a partnership built on quality, innovation, and customer satisfaction.

Price Advantage

China is the production place of flange raw materials, and YANHAO is a professional flange factory. Trusting YANHAO can help you save a lot of costs. Our unbeatable prices ensure you get the best value for your investment.

Production Capacity

As China’s leading flange manufacturer, we have advanced production equipment and many years of actual manufacturing experience. Our strong production capacity allows us to meet large orders and tight deadlines with ease.

Sales Service

Timely delivery within the specified time frame, dedicated docking service available 24/7, and one-year quality assurance. We prioritize customer satisfaction and are always here to support you.

Custom Flange Solutions

Let YANHAO be your partner in creating the perfect flange for your unique needs.

At YANHAO, we understand that your projects may require unique flange solutions.

That’s why we offer custom flange manufacturing services. Whether you need a specific size, material, or design, our team of experts will work closely with you to bring your vision to life.

From initial design to final delivery, we ensure that your custom flanges meet your exact specifications and requirements.

requirements

Confirmation

Communicate in detail to determine the requirements for flange size, material, pressure, connection method, etc.

Design drawings

Our professional engineers will design flange drawings for you. The drawings will specify the size, shape, thickness, etc., of the flange in detail.

Choose materials

Select suitable flange materials according to the requirements of the engineering project.

Customer confirmation

Send detailed information, such as the designed drawings and materials, to the customer for confirmation.

Processing sample

To ensure accuracy, first produce a sample according to the drawings and selected materials and send it to the customer for trial confirmation.

Production of bulk goods

After confirming the accuracy of the samples, proceed with mass production.

Our Business Partners and Clients

Trusted by our partners and clients for over 25 years

Sonya Martin

Norcross, GA

“The Chinese flange is good, very good, and I will buy from you next time.”

Алексей

Russia

“Still delivered in time for exceptional circumstances and didn’t delay my project!”

Ariana

Iran

“I am custom-made flanges, exactly as we expected, thank you.”

Industry knowledge

Here to share with you all sorts of relevant knowledge and information about pipe flanges.