Flange

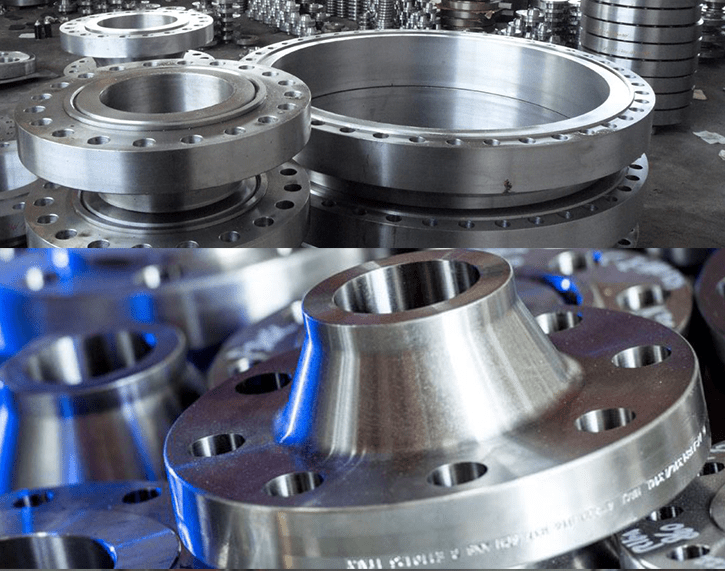

We are a Chinese flange manufacturer, capable of producing a wide variety of flange types.

We have international advanced flange production equipment, can be manufactured into superior quality flange, while the flange raw materials are used in China well-known steel producers supply of high-quality steel, these are effective in guaranteeing the quality of our flanges, but because of our Hebei, China, plant is cheap workers’ wages are also cheap, and at the same time the advantages of the industrial belt, so that we can provide you with cheaper flange prices, so choose YANHAO, will allow you to get a better product at a lower cost!

lewis Liu

sales Manager

Flanges

A flange is used to connect the two pipeline accessories, common for the round piece mounted, there is a hole in the center, surrounded by a circle of bolt holes, easy to install, and is fastened with bolts.

The use of flanges can be quickly connected to the pipeline while sealing, is not easy to leak, convenient after its maintenance and overhaul, while the flange is cheap, low cost, is a good choice in pipeline engineering.

To ensure that the flanges made by different manufacturers can be common and interchangeable, and improve circulation, there is a flange standard, which stipulates the appearance of the flange, bearing pressure, thickness, internal and external diameter size, connection mode, and bolt hole size distance.

Common flange standards include ANSI (American National Standards Institute), ASME (American Society of Mechanical Engineers), DIN (German Industrial Standards), JIS (Japanese Industrial Standards), and others.

Flange Standard

A flange standard lays down the dimensions, surface finish, facing type, marking, material, and technical specifications for flanges.

Flange Type

Flanges come in various types, each designed for specific purposes. Here are common classifications:

- Weld Neck Flange:

- Weld Neck Flange has a raised neck in the middle, which is mainly used for butt-welding connection with pipeline, and the sealing surface has various types such as raised face (RF), concave face (FM), convex face (M), tongue and groove (T), groove face (G) and full-flat surface (FF), etc., which has better sealing and can withstand greater pressure, and the common standards are ANSI, ASME, DIN, JIS, HG, GB, etc. It is mainly used in pipelines with pressure greater than 2.5MPa.

- Blind Flange:

- A blind Flange is a kind of flange without a hole in the middle, mainly used at the end of the pipeline, through the use of gaskets and then adding bolts to achieve the effect of sealing, generally, Blind Flange should use the same material and pressure with the pipeline to ensure the sealing effect, but also can be used for the temporary cut-off, inspection, maintenance, testing and other occasions.

- Socket Weld Flange:

- Socket Weld Flange has a socket in the flange bore, mainly used for welding connections with the pipeline, it is more convenient to connect, mostly used for the inconvenient use of bolts, and is also often disassembled in the low-pressure small-diameter pipelines.

- Slip-On Flange:

- Slip-On Flange has no protruding neck, the part connected with the pipe is flat, it is mainly connected by bolts, and then the gasket to achieve the sealing effect, it is inexpensive and easy to install, and it is mostly used in the medium and low-pressure pipelines which do not have high requirements on pressure and temperature.

- Threaded Flange:

- Threaded Flange inner diameter threaded, mainly used for threaded connections with pipelines, it requires that the end of the pipe needs to be processed into the corresponding threads can be used, as long as the rotary flange can be connected to the pipe, no welding, installation is extremely convenient, suitable for places where it is not convenient to weld, mostly used for low and medium-pressure and small-diameter pipeline connections.

Flange Type

Flanges come in various types, such as Weld Neck, Blind, Socket Weld, Slip-On, Threaded, Plate, and Ring Type Joint, each designed for specific applications and connecting purposes in industrial systems.

Flange Materials

Here are some commonly used flange materials:

- Carbon Steel Flange:

- ASTM A105, 20#, Q235, 16Mn, Q345b, ASTM A350 LF1,LF2 CL1/CL2,LF3 CL1/CL2, ASTM A694 F42,F46,F48,F50,F52,F56,F60,F65,F70.

- Stainless Steel Flange:

- ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8.

- Alloy Steel Flange:

- ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/Ⅲ.

Flange Material

Flange materials, including Carbon Steel, Stainless Steel, Alloy Steel, Cast Iron, Brass, Plastic, and Composite Materials, are selected based on their unique properties to ensure optimal performance in diverse industrial applications.

We are a China flange manufacturer from Asia, we have a lot of experience in flange production and are located in the “hometown of China flange” – Hebei, where there are high-quality steel suppliers, superb technology, first-class equipment, cheap labor plant costs, to ensure that we produce high-quality and low-cost flanges.

We can provide flanges of various standards such as ANSI, ASME, DIN, JIS, etc. If you need, we can also customize flanges for you according to your project.

Our flanges can be supplied with material certificates, pressure rating certificates, non-destructive testing certificates, ISO9001 certificates product qualification certificates, and third-party testing certificates to ensure that you receive high-quality flanges.

If you have any flange needs and specific project questions you can contact us via EMAIL, we will give a reply the first time.