I. Introduction to Pipe Size and Flange Size

A. Definition and Importance

Piping systems play a crucial role in various industries, such as oil and gas, chemical, and manufacturing. Within these systems, pipe size and flange size are two essential elements that significantly impact their performance and effectiveness.

Pipe size refers to the measurement of the diameter of a pipe, typically expressed in inches or millimeters. It determines the volume capacity and the flow rate of fluids within the piping system. Accurate pipe sizing ensures optimal fluid flow, minimizing pressure loss, and promoting efficient operations.

On the other hand, flange size refers to the dimensions of the flange, which is a flat or raised circular rim attached to the end of a pipe. Flanges serve as connection points between two pipes or valves, allowing for easy installation, maintenance, and control of the system. Proper flange sizing ensures a secure and leak-free connection while accommodating the required pressure and load-bearing capacity.

B. Overview of their Role in Piping Systems

Within a piping system, the pipe size and flange size must harmonize to facilitate proper fluid transportation and system functionality. The correct pipe size ensures that the desired flow rate can be achieved without excessive pressure loss or turbulence. Additionally, pipe size directly influences the selection of compatible fittings, valves, and other components.

Flange size is equally crucial, as it determines the type and size of flanges required for connecting various sections of the pipeline. Selecting the appropriate flange size ensures a tight and secure seal, preventing leakage, and maintaining system integrity. It also influences the overall structural stability of the pipeline, especially in high-pressure and high-temperature applications.

Understanding and optimizing both pipe size and flange size is essential for achieving efficient fluid flow, minimizing downtime, and ensuring the safety and reliability of the entire piping system. As industry demands continue to evolve, relying on the expertise of companies like YANHAO can provide valuable insights and superior solutions in pipe and flange sizing for optimal system performance.

II. Understanding Pipe Size

A. Measurement Standards and Terminology

Pipe sizing involves the accurate measurement and specification of the diameter of a pipe. There are several measurement standards used worldwide, including the American National Standards Institute (ANSI), the International Organization for Standardization (ISO), and the British Standard Pipe (BSP). These standards provide guidelines for pipe dimensions, tolerances, and labeling.

Terminology commonly used in pipe sizing includes “Nominal Pipe Size” (NPS) and “Outside Diameter” (OD). NPS refers to a non-dimensional size designation that represents the approximate inside diameter (ID) of the pipe. OD refers to the actual outer diameter of the pipe, which includes the thickness of the pipe wall.

B. Importance in Fluid Flow and System Design

Accurate pipe sizing is critical for optimizing fluid flow within a piping system. The diameter of the pipe directly impacts the system’s capacity to transport fluids efficiently. A smaller pipe size can lead to increased friction and pressure drop, reducing the flow rate. Conversely, an oversized pipe results in lower fluid velocity, potentially causing sedimentation and solid deposition.

Proper pipe sizing is crucial during system design to meet the desired flow rate, velocity, and pressure requirements. It ensures that the selected pipe can deliver the necessary volume of fluid without excessive pressure loss, thereby preventing energy inefficiencies and operational challenges.

C. Impact on Material Selection and Manufacturability

Pipe size influences the selection of suitable materials for construction. Smaller pipe sizes often use materials such as PVC or copper, which are cost-effective and easy to work with. In contrast, larger pipe sizes typically require materials with higher strength, corrosion resistance, and temperature tolerance, such as stainless steel or carbon steel.

Furthermore, pipe size affects the manufacturability and installation process. Smaller pipes are generally more flexible and easier to maneuver, allowing for simpler connections and layout design. Larger pipes may require specialized machinery and techniques for cutting, welding, and assembly.

YANHAO, as a specialized pipe and flange manufacturer, possesses the expertise and product range to cater to various pipe sizing requirements. With a deep understanding of measurement standards, fluid dynamics, and material properties, YANHAO offers comprehensive solutions for optimizing pipe size selection, ensuring efficient fluid flow and system performance.

III. Exploring Flange Size

A. Measurement Standards and Terminology

Flange size refers to the dimensions of the flange, which is a crucial component in piping systems for connecting and sealing pipes or valves. Flange sizes are typically designated using measurement standards such as ANSI, ISO, and DIN. These standards provide guidelines for flange dimensions, bolt-hole patterns, and face types.

Terminology commonly used in flange sizing includes “Nominal Pipe Size” (NPS), which corresponds to the pipe size, and “Flange Outside Diameter” (FOD), which refers to the outer diameter of the flange. The FOD is often larger than the pipe’s outside diameter to provide sufficient overlap for sealing and bolting.

B. Functional Variances in Flange Types

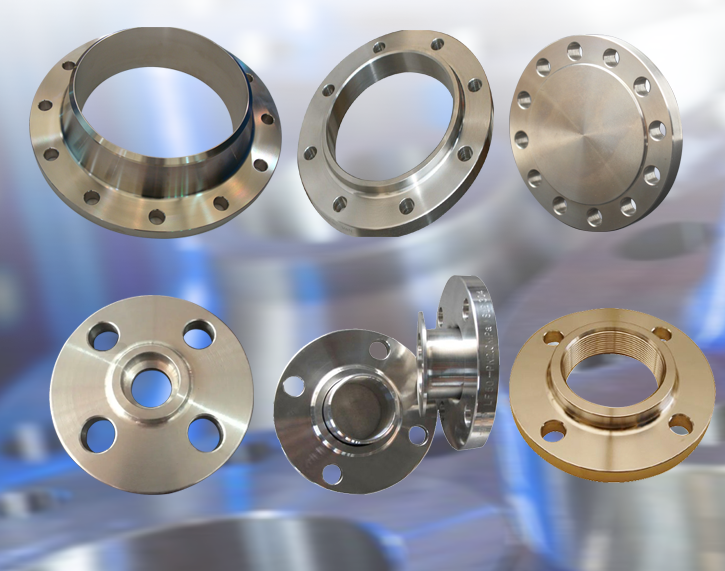

Flanges come in various types, each serving specific functions in a piping system. Some common types include slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, and blind flanges.

The size and design of flanges vary according to their intended use. For example, slip-on flanges have a lower hub height and a larger bore diameter to slide over the pipe and facilitate smooth alignment during installation. Weld neck flanges, on the other hand, have a longer neck to provide additional strength and support for high-pressure applications.

C. Considerations for Flange Installation

Installing flanges properly is essential for ensuring a secure and leak-free connection. When determining the flange size for installation, several factors need to be considered.

Firstly, the pressure and temperature requirements of the piping system must be taken into account. Flanges must be rated to withstand the pressure and temperature conditions to maintain system integrity.

Secondly, the choice of flange-facing type is important. Common face types include raised face (RF), flat face (FF), and ring-type joint (RTJ). Each facing type is designed for specific sealing requirements, and the flange size must be selected accordingly.

Additionally, bolt and gasket sizes should be considered when determining the flange size. The length and diameter of bolts and the thickness and outer diameter of gaskets will impact the overall flange size selection.

YANHAO understands the criticality of proper flange sizing and installation. With expertise in various flange types, facing options, and installation considerations, YANHAO provides comprehensive solutions for selecting and installing the right-sized flanges, ensuring secure connections and leak-free operations in piping systems.

IV. The Key Differences between Pipe Size and Flange Size

A. Understanding the Variances in Measurements

Pipe size and flange size are two distinct measurements within a piping system. Pipe size refers to the diameter of the pipe, while flange size refers to the dimensions of the flange used to connect and seal pipes.

Pipe size is typically indicated using nominal pipe size (NPS), which represents the approximate inside diameter (ID) of the pipe. Flange size, on the other hand, is specified based on the flange’s outside diameter (OD).

It’s important to note that the pipe’s outside diameter (OD) and the flange’s outside diameter (OD) are different measurements. The OD of the pipe includes the thickness of the pipe wall, while the OD of the flange does not include the pipe’s OD.

B. Significance on Piping System Integrity and Performance

The differences between pipe size and flange size have implications for the integrity and performance of a piping system.

Proper pipe sizing is crucial for maintaining fluid flow and pressure within the system. A mismatch between the pipe size and the required flow rate can lead to inefficiencies, such as increased pressure drop or reduced fluid velocity. This can affect the system’s overall performance and may require additional measures, such as pump upgrades or pipe redesign.

Flange size, on the other hand, impacts the connection and sealing of pipes. If the flange size does not match the pipe size, it can result in leaks, poor sealing, and compromised system integrity. The flange size must be chosen correctly to ensure a secure and leak-free connection between pipes.

C. Impact on Compatibility and Interchangeability

Pipe size and flange size compatibility is essential for the interchangeability of components within a piping system. The flange’s size must be selected to match the corresponding pipe size to ensure a proper fit.

However, it’s important to note that flanges of the same size may have different pressure ratings or facing types, which impacts their specific functions and usage. It is crucial to consider not only the size but also the specifications of the flanges to ensure compatibility with the piping system.

In cases where pipe size and flange size are not identical, transitions or adapters may be required to connect pipes and flanges of different sizes. These transitions should be properly designed and implemented to maintain system integrity and performance.

YANHAO understands the differences between pipe size and flange size and their respective impact on piping system design and functionality. With expertise in pipe and flange manufacturing, YANHAO ensures the compatibility and interchangeability of components, providing reliable and efficient solutions for a wide range of piping needs.

V. YANHAO’s Expertise and Solutions in Pipe and Flange Industry

A. Overview of YANHAO’s Experience and Specializations

YANHAO has extensive experience and specializations in the pipe and flange industry. With a strong commitment to quality, innovation, and customer satisfaction, YANHAO has established itself as a leading provider of pipe and flange solutions.

YANHAO’s expertise includes manufacturing a wide range of pipes and flanges in various materials, sizes, and specifications. The company has a diverse portfolio that caters to different industries, such as oil and gas, petrochemicals, power generation, and water treatment.

YANHAO’s team of highly skilled engineers and technicians work closely with clients to understand their specific requirements and provide tailored solutions. The company’s manufacturing facilities are equipped with advanced technologies and state-of-the-art machinery, ensuring precision, efficiency, and consistent quality in every product.

B. Innovative Approaches to Pipe and Flange Sizing and Selection

YANHAO employs innovative approaches to pipe and flange sizing and selection, considering factors such as pressure, temperature, fluid characteristics, and system requirements.

For pipe sizing, YANHAO utilizes advanced hydraulic analysis and computational fluid dynamics (CFD) techniques to optimize flow rates, minimize pressure losses, and ensure efficient system performance. The company considers factors such as fluid properties, pipe material, and desired flow velocities to recommend the most suitable pipe size.

When it comes to flange sizing and selection, YANHAO takes a comprehensive approach. The company considers flange standards, such as ANSI, ISO, and DIN, as well as facing types and flange materials, to ensure compatibility, proper sealing, and system integrity. YANHAO also factors in bolt and gasket sizes, taking a holistic approach to flange design and sizing.

C. Case Studies Demonstrating YANHAO’s Professionalism and Success

YANHAO has a proven track record of professionalism and success in delivering pipe and flange solutions across various industries.

In one case study, YANHAO collaborated with a petrochemical company to design and supply a piping system for their new plant. YANHAO’s team conducted detailed analysis, considering factors such as fluid properties, pressure drop, and system requirements. The company provided a comprehensive solution that included the sizing and selection of pipes, flanges, valves, and fittings, ensuring optimal performance and efficiency.

Another case study involved a power generation project, where YANHAO was responsible for supplying and installing large-diameter pipes and flanges. YANHAO’s expertise in handling complex projects and its commitment to quality and safety were instrumental in the successful completion of the project, meeting stringent requirements and timelines.

These case studies highlight YANHAO’s professionalism, technical proficiency, and ability to deliver tailored pipe and flange solutions that meet the unique needs of each client.

With its expertise, innovative approaches, and a proven track record of success, YANHAO stands as a reliable partner for all pipe and flange requirements, providing comprehensive solutions that ensure efficiency, reliability, and performance in piping systems.

VI. Conclusion

At YANHAO, we understand the crucial role of accurate pipe and flange sizing in optimizing the performance, efficiency, and safety of piping systems. Our team is well-versed in the key differences and impacts of proper sizing.

We know that undersized pipes can lead to excessive pressure drops, restricted flow rates, and reduced system efficiency. On the other hand, oversized pipes can result in inefficient operation, increased capital costs, and unnecessary energy consumption. That’s why accurate pipe sizing is essential in achieving the optimal balance between flow rates, pressure drops, and system requirements.

When it comes to flange sizing, we recognize the criticality of proper sealing, system integrity, and compatibility. Inadequate flange sizing can result in leaks, blowouts, and potential safety hazards. That’s why we pay close attention to factors such as facing types, materials, and bolt and gasket sizes. We ensure secure connections, reliable sealing, and efficient operation of the entire piping system.

At YANHAO, we take pride in our expertise in pipe and flange sizing, which allows us to optimize piping systems efficiently. Our advanced analytical techniques, computational fluid dynamics, and close collaboration with clients enable us to deliver accurate and customized sizing solutions.

We understand the importance of considering factors such as pressure, temperature, fluid characteristics, and specific system requirements. By taking these into account, we can recommend the most efficient and reliable pipe and flange sizes for our clients’ unique needs.

Leaning on our expertise, our clients can enjoy enhanced system performance, minimized pressure losses, reduced energy consumption, and increased operational efficiency. Our dedication to quality, innovation, and customer satisfaction ensures that our solutions meet the highest standards and provide long-term value to our clients.

In conclusion, accurate pipe and flange sizing is crucial, and at YANHAO, we excel in providing optimized solutions. With our comprehensive expertise, we deliver efficient operations, cost savings, and improved system reliability for our clients.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.