I. Introduction

In various industries, accurate flange dimensions play a crucial role in ensuring the safe and efficient operation of equipment and systems. Flanges are used to connect pipes, valves, and other components, forming leak-tight joints that withstand high pressures and temperatures. However, any deviation from the required dimensions can lead to leaks, misalignments, and costly failures.

Accurate flange dimensions are particularly important in industries such as oil and gas, chemical, petrochemical, power generation, and pharmaceuticals, where the integrity of systems is of utmost importance. In these industries, maintaining the safety of workers, protecting the environment, and avoiding costly downtime are key priorities.

To ensure uniformity and reliability in flange dimensions, the American Society of Mechanical Engineers (ASME) developed ASME B 16.5 as a widely recognized standard. ASME B 16.5 provides detailed guidelines for the calculation and specification of flange dimensions, including size, pressure rating, flange facing, bolt-hole patterns, and tolerances. This standard ensures that flanges produced by different manufacturers are interchangeable, facilitating smooth installation and maintenance processes.

ASME B 16.5 is accepted and followed globally in various industries. It sets the benchmark for flange dimensions and ensures compatibility and standardization across different applications and regions. Adhering to this standard enhances efficiency, minimizes risks of leaks or failures, and facilitates system integration and maintenance.

By complying with ASME B 16.5, companies can demonstrate their commitment to safety, quality, and regulatory compliance. Moreover, using accurate flange dimensions according to this standard reduces rework, repairs, and downtime, yielding cost savings and operational efficiencies.

At YANHAO, we understand the importance of accurate flange dimensions and the significance of ASME B 16.5 compliance. With our expertise and experience, we deliver precise and reliable flange dimension calculations tailored to the specific requirements of our clients. Our dedicated team utilizes advanced technology and follows industry best practices to ensure consistent and accurate results.

We have earned the trust of numerous clients across various industries through our commitment to customer satisfaction. Our track record includes successful projects where our precise flange dimension calculations have contributed to the smooth operation and reliability of systems.

When it comes to flange dimension calculations, partner with YANHAO for your needs. Contact us today to discuss your requirements and experience our reliable and precise solutions.

II. Flange Dimension Calculation Methods

ASME B 16.5 provides clear guidelines for calculating flange dimensions, ensuring consistency and reliability across various industries. The calculation methods in ASME B 16.5 are based on several factors, including pressure, temperature, and flange type. These factors are crucial in determining the appropriate dimensions for flanges to ensure their integrity and performance.

- Pressure Considerations:

- Flanges must be designed to withstand the internal pressure exerted by the fluid or gas flowing through the system.

- The calculation of flange dimensions takes into account the maximum expected pressure, ensuring that the flange can maintain a leak-tight seal under these conditions.

- ASME B 16.5 provides formulas and equations to calculate the minimum required flange thickness based on pressure considerations.

2. Temperature Considerations:

- Flanges must also be able to withstand the temperature of the fluid or gas flowing through the system.

- The calculation of flange dimensions considers the maximum expected temperature and the corresponding thermal expansion and contraction effects on the flange.

- ASME B 16.5 provides guidelines for flange dimensions that account for thermal expansion and contraction, ensuring dimensional stability and maintaining the required seal.

3. Flange Type Considerations:

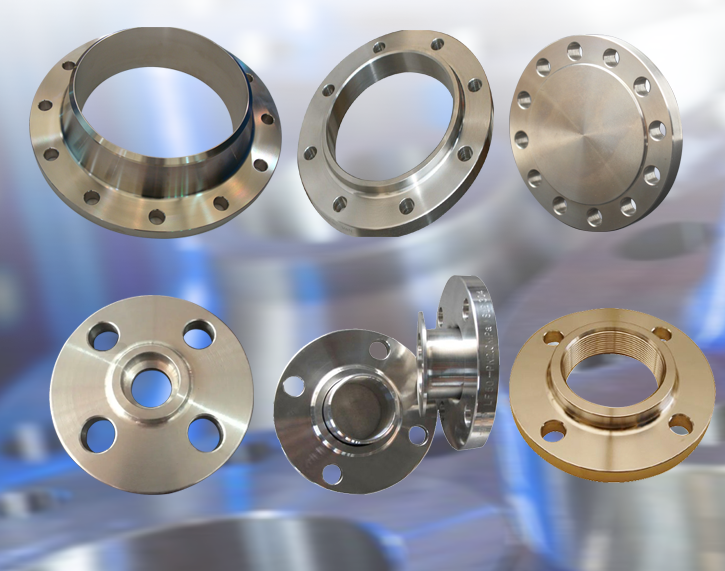

- ASME B 16.5 covers different types of flanges, including welding neck, slip-on, socket weld, threaded, lap joint, and blind flanges.

- Each flange type has specific requirements and considerations, such as the flange facing, bolt-hole patterns, and tolerances.

- The calculation methods in ASME B 16.5 account for these flange-type considerations to determine the appropriate dimensions.

4. Formulas and Equations:

ASME B 16.5 provides a set of formulas and equations that are used to calculate various dimensions of flanges. These formulas take into account factors such as pressure, temperature, material properties, and safety factors. Here are some of the key formulas and equations used in flange dimension calculations:

Flange Outside Diameter (OD):

- The outside diameter of a flange is calculated using the following equation:

OD = Nominal Pipe Size + 2 times Flange Thickness

Flange Inside Diameter (ID):

- The inside diameter of a flange is calculated using the following equation:

ID = Nominal Pipe Size – 2 times (Flange Thickness + 1/16 inch)

Flange Bolt Circle Diameter (BCD):

- The bolt circle diameter is calculated based on the number of bolt holes and their diameter. The formula used is:

BCD = (N-3) × Bolt Hole Diameter

Flange Bolt Hole Diameter (BHD):

- The bolt hole diameter is determined based on the bolting requirements of the flange. The formula used is:

BHD = Nominal Pipe Size / 8

Flange Thickness:

- The minimum required flange thickness is calculated using the following equation:

t = (P × D) / (2 × S × F × E) - Where:

t = Minimum required flange thickness

P = Design pressure

D = Flange outside diameter

S = Allowable Stress

F = Design factor (a factor that considers flange type and service conditions)

E = Joint Efficiency factor (typically 0.85 for raised face flanges)

These formulas and equations are just a few examples of the calculations used in ASME B 16.5 for determining various dimensions of flanges. It is crucial to carefully follow these calculations to ensure the appropriate sizing and compatibility of flanges in different applications.

It is essential to accurately follow the calculation methods outlined in ASME B 16.5 to ensure flange dimensions that meet the specific requirements of each application. Adhering to these guidelines ensures the compatibility, interchangeability, and reliability of flanges produced by different manufacturers.

III. Importance of Expertise in Flange Dimension Calculations

Accurate flange dimension calculations are crucial for ensuring the integrity, safety, and performance of industrial piping systems. Expertise plays a critical role in accurately interpreting requirements and applying the calculation methods specified in standards like ASME B 16.5. Here are some reasons highlighting the importance of expertise in flange dimension calculations:

- Interpretation of Requirements:

- Flange dimension calculations involve interpreting various requirements, such as pressure, temperature, material properties, and safety factors.

- An expert in flange design understands these requirements and can accurately interpret them to ensure the calculated dimensions meet the specified criteria.

- Expertise helps in identifying any additional considerations, such as corrosion, erosion, or vibration, that may impact the flange design and dimension calculations.

2. Knowledge and Experience:

- Accurate flange dimension calculations require a deep understanding of the underlying principles, equations, and formulas used in the calculations.

- Experts possess the knowledge and experience necessary to select the appropriate formulas and equations for each specific scenario.

- They are familiar with the limitations, assumptions, and safety factors inherent in the calculation methods and can apply them correctly.

3. Understanding of Flange Types and Applications:

- Various types of flanges have different design considerations and calculation methods.

- An expert in flange dimension calculations has a comprehensive understanding of different flange types, their applications, and the specific requirements associated with each type.

- They can accurately select the appropriate calculation methods and dimensions based on the specific flange type and its intended use.

YANHAO has extensive expertise in flange design and dimension calculations. With years of experience in designing and manufacturing flanges, YANHAO engineers possess in-depth knowledge of industry standards and calculation methods. They are skilled in accurately interpreting requirements, selecting the correct formulas, and applying them to ensure the proper sizing and dimensions of flanges.

IV. Authoritativeness of ASME B 16.5

ASME B 16.5 is a widely recognized and authoritative standard for flange dimensions, materials, and design in the industry. It was developed and maintained by the American Society of Mechanical Engineers (ASME), a prestigious organization known for developing codes and standards related to mechanical engineering. Here are some reasons highlighting the authoritativeness of ASME B 16.5:

- Development Process:

- ASME B 16.5 is developed through a rigorous process that involves input from a diverse group of experts, including engineers, manufacturers, researchers, and end-users.

- The development process includes thorough reviews, discussions, and revisions to ensure that the standard reflects the best practices, technological advancements, and industry consensus regarding flange dimensions and design.

- The consensus-based approach ensures that ASME B 16.5 represents the collective expertise and experience of key stakeholders in the field.

2. Consistency, Reliability, and Compatibility:

- ASME B 16.5 provides a consistent and reliable framework for flange dimensions, materials, and design across various industries and applications.

- The standard ensures compatibility and interchangeability of flanges from different manufacturers, simplifying procurement, installation, and maintenance processes.

- By adhering to ASME B 16.5, manufacturers and users can have confidence that flanges will meet the required specifications and function reliably in their intended applications.

3. Adherence to ASME Standards by YANHAO:

- YANHAO recognizes the significance of adhering to recognized industry standards like ASME B 16.5 in the design and manufacturing of flanges.

- YANHAO ensures that its products comply with the requirements and recommendations outlined in ASME B 16.5, including flange dimensions, materials, and design considerations.

- By adhering to ASME standards, YANHAO demonstrates its commitment to producing high-quality, reliable, and compatible flanges that meet industry requirements and customer expectations.

The authoritativeness of ASME B 16.5 is based on its development process, consensus-driven approach, and its role in ensuring consistency, reliability, and compatibility in flange design and dimensions. By adhering to this standard, companies like YANHAO demonstrate their commitment to excellence and contribute to the overall safety and efficiency of industrial piping systems.

V. Trustworthiness in Flange Dimension Calculations

Trustworthiness in flange dimension calculations is crucial for ensuring the integrity, safety, and performance of industrial piping systems. Several factors contribute to establishing trust in these calculations, including quality control measures and certifications. Here are some reasons highlighting the importance of trustworthiness in flange dimension calculations:

- Quality Control Measures:

- Accurate flange dimension calculations require rigorous quality control measures throughout the entire design and manufacturing process.

- Quality control measures include verifying the accuracy of input parameters, conducting thorough checks of calculations, and reviewing designs for compliance with applicable standards and specifications.

- Proper documentation and record-keeping are also essential for traceability and accountability.

2. Certifications:

- Certifications play a vital role in establishing trustworthiness in flange dimension calculations.

- Certifications demonstrate that a company has undergone rigorous assessments and evaluations to ensure compliance with industry standards and best practices.

- Certifications validate that a company’s processes, systems, and products meet or exceed the specified requirements, providing assurance to customers and stakeholders.

3. YANHAO’s Commitment to Quality Control and Certifications:

- YANHAO understands the importance of trustworthiness in flange dimension calculations and is committed to maintaining the highest standards of quality control.

- YANHAO implements robust quality control measures throughout the entire design and manufacturing process to ensure accurate calculations and reliable products.

- These certifications demonstrate YANHAO’s dedication to quality and provide customers with confidence in the accuracy and reliability of their flanges.

By implementing stringent quality control measures and earning certifications, YANHAO establishes trustworthiness in its flange dimension calculations. Customers can have confidence in YANHAO’s ability to deliver accurate, reliable, and compliant products that meet the highest quality standards.

YANHAO’s commitment to quality control and certifications ensures that their flanges are designed and manufactured with precision, contributing to the overall safety, efficiency, and performance of industrial piping systems.

VI. Conclusion

Accurate flange dimensions are critical for the integrity, safety, and efficiency of industrial piping systems. ASME B 16.5 serves as a widely recognized and authoritative standard for flange dimensions, materials, and design. YANHAO, as a trusted provider of flange dimension calculations, understands the importance of adhering to this standard and ensuring accuracy in their designs.

YANHAO’s commitment to quality control measures, such as rigorous checks and certifications like ISO 9001:2015 and ASME U and S stamps, establishes their expertise and trustworthiness in flange dimension calculations. Customers can rely on YANHAO to deliver precise, compliant, and reliable flanges for their specific applications.

If you are in need of precise and reliable flange dimension calculations, YANHAO is the provider you can rely on. Contact YANHAO today to discuss your specific requirements and benefit from their expertise in ensuring accurate and trustworthy flange dimensions for your industrial piping system.

Remember, choosing a trusted and experienced provider like YANHAO is essential to ensure the safety and performance of your piping systems. Contact YANHAO now for reliable and precise flange dimension calculations.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.