I. Introduction

Welcome to the YANHAO (盐浩) blog! As a professional flange manufacturer based in Cangzhou, Hebei, China, we take pride in offering a wide range of flange fittings, including standard flanges compliant with ANSI, DIN, and JIS, as well as customized non-standard flanges in stainless steel, alloy steel, and carbon steel materials. Our aim is to expand our product reach to the global market, particularly in Europe and North America.

In this blog post, titled “How to Customize Non-Standard Flanges?”, we will delve into the process of customizing non-standard flange fittings and highlight its significance. Customized flanges are the ideal choice for meeting specific requirements, whether it’s adapting to unique application scenarios or enhancing performance efficiency. We will introduce you to our professional engineering team at YANHAO, our state-of-the-art manufacturing facilities, and our stringent quality control processes to establish our expertise, authoritativeness, and trustworthiness.

In the following sections, we will provide a comprehensive insight into the customization process of non-standard flanges. Starting from initial consultations and discussions, we will closely collaborate with you to understand your project requirements and specifications. Our engineering team will utilize advanced software and tools for design and modeling to ensure precise custom designs. In terms of material selection, we will discuss the characteristics and suitability of different materials to meet your performance demands.

We will also unveil the various manufacturing techniques employed by YANHAO during the production of non-standard flanges, emphasizing our comprehensive quality control measures. Rigorous testing and inspection processes after production will guarantee product reliability and performance. Furthermore, through case studies, we will showcase the successful application of customized non-standard flanges in diverse industries, solving unique challenges.

Through this blog post, we aim to provide you with insights into YANHAO’s commitment as a trusted flange manufacturer, dedicated to delivering tailored solutions to our customers. Our goal is to offer exceptional product quality and a seamless customer experience, backed by our expertise, authoritativeness, and trustworthiness. Please continue reading to explore the boundless possibilities of customizing non-standard flange fittings.

II. Understanding Non-Standard Flanges

A. Definition of non-standard flanges and their significance in specialized applications:

When it comes to non-standard flanges, I find them truly fascinating. These flanges are unique and deviate from standard specifications in terms of size, shape, material, or functionality. Their significance lies in their ability to address the diverse and specialized needs of various industries. For instance, in the oil and gas sector, where extreme temperatures and pressures are commonplace, non-standard flanges ensure a secure and reliable connection between pipelines, preventing leakage and maintaining operational integrity. Similarly, in the aerospace industry, non-standard flanges play a crucial role in ensuring the structural integrity and seamless functioning of complex aircraft systems. These examples highlight the vital role that non-standard flanges play in specialized applications, enabling industries to overcome unique challenges and achieve optimal performance.

B. The advantages and benefits of customizing flanges to meet specific requirements:

Having worked closely with clients on numerous projects, I have witnessed firsthand the advantages and benefits of customizing flanges to meet specific requirements. Let me share some of these benefits with you:

- Tailored Solutions: Customizing flanges allows us to provide tailored solutions that precisely meet the requirements of our client’s projects. By taking into account factors such as size, shape, and material, we ensure that the flanges seamlessly integrate into the existing infrastructure, enhancing overall system efficiency.

- Enhanced Compatibility: One of the major advantages of customization is the ability to ensure compatibility with existing equipment and structures. We understand that every project has unique dimensions and configurations, and by customizing flanges, we can ensure a perfect fit, eliminating the need for costly modifications or replacements.

- Optimal Performance: Customized flanges are designed to optimize system performance. Whether it’s improving flow characteristics, reducing pressure drops, or enhancing structural stability, we carefully engineer the flanges to meet the specific demands of the application. This results in improved efficiency, reliability, and safety.

- Cost Efficiency: While customization may seem like an additional investment, it often leads to long-term cost savings. By providing flanges that precisely meet the project requirements, we minimize downtime, maintenance costs, and potential operational disruptions. This cost-efficiency contributes to the overall success of the project.

C. The importance of precision and accuracy in non-standard flange production:

In the realm of non-standard flange production, precision, and accuracy are of paramount importance. As an expert in the field, I understand the critical role these factors play in delivering high-quality flanges. The unique nature of non-standard flanges demands meticulous attention to detail at every stage of the production process.

At YANHAO, we utilize advanced manufacturing techniques and cutting-edge technologies to ensure exceptional precision and accuracy. Our team of skilled professionals meticulously controls dimensions, tolerances, surface finishes, and material selection. We leave no room for compromise, ensuring that each flange meets the precise specifications of the client and complies with stringent industry standards and quality assurance protocols.

III. Customization Process

A. Initial Consultation

As a manufacturer specializing in non-standard flanges, I recognize the utmost importance of establishing effective communication with our customers from the very beginning. Through open and transparent dialogue, we can ensure a successful customization process that meets their unique requirements.

- Emphasizing Effective Communication:

Effective communication serves as the foundation for a fruitful collaboration. We actively listen to our customers, encouraging them to share their vision, project requirements, and expectations. By fostering a strong rapport, we can better understand their needs and work together to achieve their desired outcomes. Regular and clear communication channels enable us to address any concerns, clarify uncertainties, and provide timely updates throughout the customization process.

- Understanding Project Requirements:

During the initial consultation, we delve into the project requirements in detail. We take the time to comprehensively understand the specifications and technical aspects involved. By gathering thorough information about the desired flange characteristics, such as size, pressure rating, temperature range, and compatibility with specific media, we can tailor our approach to meet these specific demands.

Furthermore, understanding the intended application of the non-standard flanges is vital. Whether it is for a specialized industry, such as oil and gas, chemical, or manufacturing, or for a specific equipment or system, such as pipelines or pressure vessels, we take into account the unique environmental conditions and performance expectations. This enables us to develop a clear understanding of how the customized flanges will function within the intended application, ensuring optimal performance and safety.

By investing time and effort in the initial consultation phase, we establish a solid foundation for a successful customization process. Through effective communication and a comprehensive understanding of project requirements, specifications, and intended application, we can proceed to the next stages of engineering, material selection, manufacturing, and testing with confidence and precision.

B. Engineering and Design

At YANHAO, we pride ourselves on the expertise and involvement of our experienced engineers throughout the customization process of non-standard flanges. Our engineering team plays a pivotal role in transforming project requirements into tailored flange designs that meet the highest standards of quality and functionality.

- Involvement of Experienced Engineers:

Our team of engineers brings a wealth of knowledge and expertise to the table. With their deep understanding of flange design principles, materials, and industry standards, they provide invaluable insights and guidance throughout the customization process. Their experience enables them to tackle complex challenges, offer innovative solutions, and ensure the feasibility and practicality of customized flange designs.

- Analyzing Requirements and Developing Tailored Designs:

To develop tailored flange designs, our engineers meticulously analyze the project requirements gathered during the initial consultation phase. They carefully consider factors such as dimensions, pressure ratings, temperature ranges, material compatibility, and structural integrity. By taking these requirements into account, they can develop designs that precisely meet the customer’s specifications and intended application.

Our engineers utilize advanced engineering tools, software, and modeling techniques to assist in the design process. Computer-Aided Design (CAD) software allows them to create detailed 3D models of the flange designs, facilitating visualization and accurate representation. Finite Element Analysis (FEA) tools aid in simulating and assessing the performance, strength, and durability of the customized flanges under different operating conditions. This enables our engineers to optimize the design for reliability, efficiency, and cost-effectiveness.

- Utilization of Advanced Software and Tools:

To ensure precision and accuracy in the design phase, our engineers leverage advanced software and tools. These tools enable them to perform detailed calculations, analyze stress distribution, evaluate performance factors, and verify compliance with industry standards and codes. By leveraging these technologies, we can efficiently develop tailored flange designs that meet the customer’s requirements while adhering to rigorous quality and safety standards.

Through the expertise of our experienced engineers, the careful analysis of project requirements, and the utilization of advanced software and tools, we can confidently deliver customized flange designs that excel in performance, durability, and efficiency. Our engineering and design capabilities ensure that every non-standard flange we produce meets the highest standards of quality and functionality.

C. Material Selection

When it comes to non-standard flange production, selecting the right material is crucial to ensure optimal performance, durability, and reliability in specific applications. At YANHAO, we offer a diverse range of materials for customization, allowing us to tailor the flanges to meet our customers’ unique requirements. Here’s an overview of the material selection process:

- Range of Materials:

We provide a wide selection of materials suitable for non-standard flange production. This includes various grades of stainless steel, alloy steel, and carbon steel. Each material has distinct properties that make it suitable for specific applications. Stainless steel, for example, offers excellent corrosion resistance and is commonly used in industries such as chemical, pharmaceutical, and food processing. Alloy steel provides enhanced strength and temperature resistance, making it ideal for high-pressure and high-temperature applications. Carbon steel, on the other hand, offers a balance of strength and affordability, making it a versatile choice for various industries.

- Considerations for Material Selection:

The choice of material depends on several factors, including the application and performance requirements of the flange. Here are some key considerations:

a. Corrosion Resistance: If the flange will be exposed to corrosive substances or environments, selecting a material with high corrosion resistance, such as stainless steel, is essential to ensure longevity and reliability.

b. Temperature and Pressure: Consider the operating temperature and pressure conditions the flange will be subjected to. Different materials have varying temperature and pressure ratings, so it’s crucial to choose a material that can withstand the intended conditions without compromising performance or safety.

c. Compatibility: Compatibility with other system components is crucial to avoid galvanic corrosion or chemical reactions. It’s important to assess the compatibility of the selected material with the fluids or gases that will flow through the system.

d. Strength and Mechanical Properties: Evaluate the required strength, stiffness, and mechanical properties based on the application and load requirements. Alloy steel, for example, offers high tensile strength and toughness, making it suitable for heavy-duty applications.

e. Cost Considerations: Budget constraints may also influence material selection. It’s important to strike a balance between performance requirements and cost-effectiveness to ensure the best value for the customer.

At YANHAO, our team of experts assists customers in selecting the most suitable material for their non-standard flanges. By considering the specific application, performance requirements, and industry standards, we ensure that the chosen material aligns with the intended use, providing optimal performance, durability, and reliability.

D. Manufacturing Process

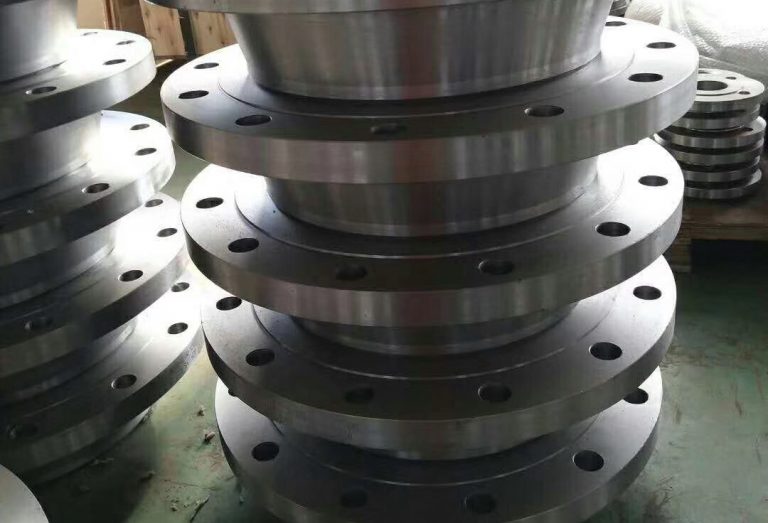

At YANHAO, we take pride in our state-of-the-art production facilities and advanced manufacturing capabilities. Our commitment to quality and precision allows us to deliver exceptional non-standard flanges that meet the exact specifications and requirements of our customers. Here’s an overview of our manufacturing process:

- Production Facilities and Capabilities:

Our manufacturing facilities are equipped with modern machinery, cutting-edge technology, and skilled personnel. We have dedicated areas for different stages of production, including cutting, shaping, machining, and finishing. Our facilities are designed to handle a wide range of flange sizes, materials, and customization requirements.

- Manufacturing Techniques:

To ensure the highest quality and accuracy, we employ various advanced manufacturing techniques for non-standard flanges. These techniques include:

a. Precision Cutting: We utilize advanced cutting methods, such as laser cutting or waterjet cutting, to accurately shape the flange blanks according to the specified dimensions.

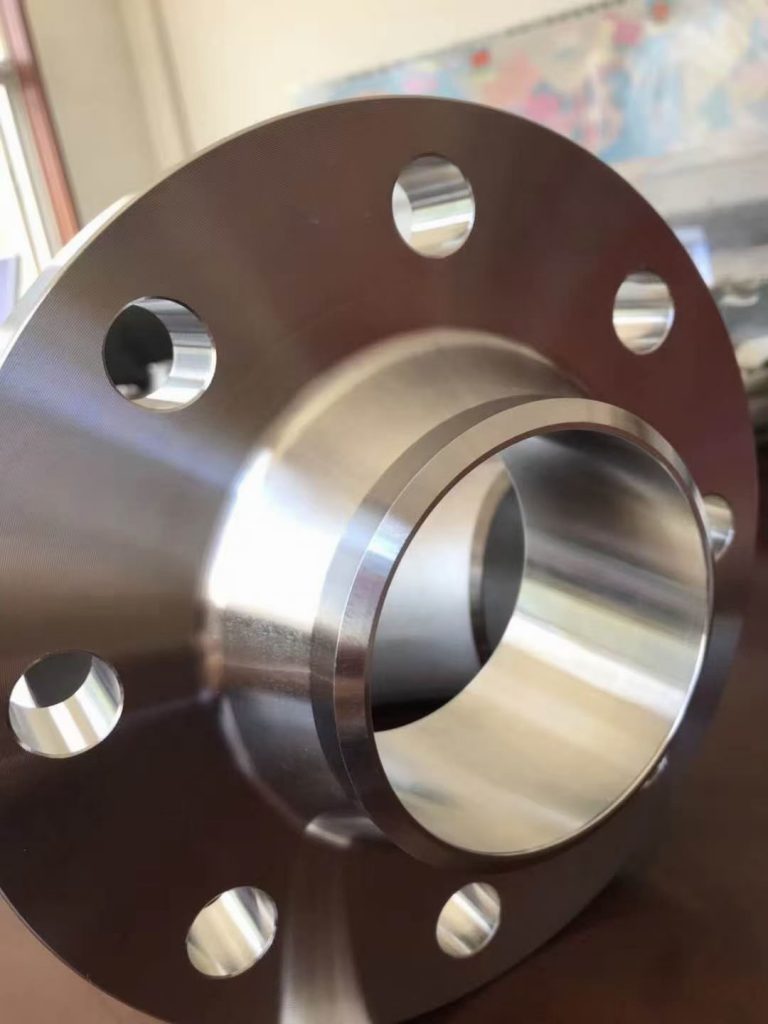

b. Machining: Our skilled technicians use CNC (Computer Numerical Control) machining techniques to precisely create the required features, such as bolt holes, grooves, and flange faces, ensuring proper alignment and compatibility.

c. Forming and Shaping: We employ techniques like forging, rolling, or pressing to shape the flanges, achieving the desired contours and dimensions. These methods ensure the structural integrity and strength of the flanges.

d. Welding and Assembly: When necessary, we perform welding operations using qualified welders and advanced welding techniques to join different components of the flanges securely. Assembly processes are meticulously executed to ensure proper alignment and functionality.

- Quality Control Measures:

Maintaining high-quality standards is paramount throughout our manufacturing process. We have implemented robust quality control measures to ensure that every non-standard flange meets the required specifications and industry standards. Our quality control practices include:

a. Material Inspection: We conduct thorough inspections of incoming materials to verify their compliance with the specified requirements and ensure their suitability for the intended application.

b. Dimensional Accuracy: Precise measurements and dimensional checks are performed at various stages of the manufacturing process to ensure that the flanges conform to the exact specifications.

c. Non-Destructive Testing (NDT): We employ NDT techniques, such as ultrasonic testing or magnetic particle inspection, to detect any internal or surface defects that could compromise the integrity of the flanges.

d. Visual Inspection: Trained inspectors conduct visual examinations to assess the surface finish, weld quality, and overall appearance of the flanges, ensuring they meet the desired standards.

e. Performance Testing: We subject the finished flanges to rigorous performance tests, such as pressure testing or load testing, to verify their strength, leak resistance, and functionality under realistic operating conditions.

By implementing these comprehensive quality control measures, we guarantee that every non-standard flange manufactured at YANHAO meets the highest standards of quality, reliability, and performance.

E. Testing and Inspection

At YANHAO, we understand the critical importance of rigorous testing and inspection procedures in ensuring the quality, reliability, and performance of our non-standard flanges. We are committed to delivering products that meet or exceed the highest industry standards. Here’s how we prioritize testing and inspection throughout our manufacturing process:

- Importance of Rigorous Testing and Inspection Procedures:

Testing and inspection are integral parts of our manufacturing process as they serve multiple crucial purposes. By subjecting our flanges to comprehensive tests and inspections, we can:

a. Verify Quality: Rigorous testing helps us ensure that our flanges meet the specified quality standards and are free from defects or imperfections.

b. Ensure Reliability: Thorough testing allows us to assess the reliability of our flanges, ensuring they can perform under demanding conditions and meet the expected lifespan.

c. Validate Performance: By conducting performance tests, we verify that our flanges can withstand the intended loads, pressures, and temperatures while maintaining their functionality.

d. Enhance Safety: Stringent testing procedures help us identify and address any potential safety risks associated with our flanges, ensuring the protection of personnel and assets.

- Adherence to International Standards and Certifications:

At YANHAO, we adhere to internationally recognized standards and certifications to guarantee the quality and reliability of our non-standard flanges. We closely follow standards such as:

a. ASME (American Society of Mechanical Engineers): We ensure that our flanges conform to the standards set by ASME, including their dimensional requirements, materials, and pressure ratings.

b. ANSI (American National Standards Institute): Our flanges comply with ANSI standards, ensuring compatibility and interchangeability with other ANSI-compliant components.

c. ASTM (American Society for Testing and Materials): We use ASTM standards to guide the selection of materials and perform material testing, ensuring their mechanical and chemical properties meet the required specifications.

d. ISO (International Organization for Standardization): Our manufacturing processes and quality management systems are aligned with ISO standards, providing assurance of consistent quality and customer satisfaction.

By adhering to these international standards and certifications, we demonstrate our commitment to delivering flanges of the highest quality and reliability.

- Use of Advanced Testing Equipment:

To ensure accurate and reliable results, we employ advanced testing equipment and techniques. This includes:

a. Non-Destructive Testing (NDT): We utilize NDT methods such as ultrasonic testing, magnetic particle inspection, and liquid penetrant testing to detect any internal or surface defects without causing damage to the flanges.

b. Pressure Testing: We subject our flanges to hydrostatic or pneumatic pressure tests to verify their strength, leak resistance, and ability to withstand the specified operating conditions.

c. Dimensional Inspection: Precise measurement tools, such as coordinate measuring machines (CMM) and optical measurement systems, are used to verify the dimensional accuracy and alignment of our flanges.

d. Material Testing: We employ advanced techniques, such as spectroscopy and mechanical testing, to analyze the composition, mechanical properties, and performance characteristics of the materials used in our flanges.

By utilizing advanced testing equipment, we ensure that our non-standard flanges undergo a thorough evaluation, providing our customers with the assurance of reliability, performance, and safety.

At YANHAO, we are dedicated to delivering non-standard flanges that have undergone meticulous testing and inspection, meeting the highest quality standards and exceeding customer expectations.

IV. Advantages of Customized Non-Standard Flanges

When it comes to flange solutions, off-the-shelf options may not always meet the unique requirements of different industries and applications. That’s where customized non-standard flanges come into play. At YANHAO, we specialize in providing tailored flange solutions that offer several advantages over standard flanges. Let’s explore the benefits of opting for customized non-standard flanges:

A. Address Specific Needs and Requirements:

Customized non-standard flanges are designed to address the specific needs and requirements of customers across various industries. Whether it’s oil and gas, chemical, power generation, or any other sector, these flanges can be tailored to accommodate specialized applications. By collaborating closely with our customers, we ensure that the flanges we produce are precisely engineered to meet their specific project requirements, including dimensions, pressure ratings, materials, and connection types. This customization enables a perfect fit and seamless integration with existing systems and equipment.

B. Enhanced Functionality and Improved Efficiency:

By customizing flanges, we can enhance functionality and optimize performance. Tailored flanges allow for improved fluid flow, reduced turbulence, and minimized pressure drops, resulting in enhanced system efficiency. Additionally, we can incorporate unique features such as flange faces, sealing surfaces, or special connections to meet specific operational demands. These customizations can enhance the overall performance and reliability of the flange system, leading to improved productivity and reduced downtime.

C. Cost-Effectiveness in the Long Term:

While customized non-standard flanges may require an initial investment, they often prove to be cost-effective in the long term. By precisely addressing the application requirements, these flanges minimize the risk of system failures, leaks, or malfunctions. This, in turn, reduces downtime and maintenance costs associated with repairs and replacements. Customized flanges also offer improved compatibility with existing equipment, reducing the need for costly modifications or adaptors. Moreover, their optimized design and performance can lead to energy savings, further contributing to cost reduction over time.

In conclusion, opting for customized non-standard flanges provides numerous advantages for industries seeking tailored solutions. By addressing specific needs and requirements, these flanges offer enhanced functionality, improved efficiency, and long-term cost-effectiveness. At YANHAO, we specialize in delivering customized flanges that meet the unique demands of our customers, ensuring optimal performance, reliability, and customer satisfaction.

V. Case Studies

A. Real-Life Examples of Successful Non-Standard Flange Customization Projects:

- Oil and Gas Industry: In a recent project for an offshore oil and gas facility, our team at YANHAO collaborated with the client to customize non-standard flanges for subsea pipeline connections. The project required flanges that could withstand high-pressure and corrosive environments. Through careful material selection and engineering analysis, we developed customized flanges using corrosion-resistant alloys with enhanced sealing capabilities. The tailored flanges successfully met the stringent project specifications, ensuring reliable and leak-free connections in challenging offshore conditions.

- Power Generation Sector: YANHAO partnered with a major power plant to provide customized non-standard flanges for their steam turbine system. The project involved replacing outdated flanges with tailored solutions that could withstand high-temperature and high-pressure conditions. Our experienced engineers analyzed the system requirements and designed flanges with improved heat resistance and structural integrity. The custom flanges not only resolved the challenges posed by the demanding operating conditions but also improved the overall efficiency and safety of the steam turbine system.

B. Unique Challenges Solved by Customized Solutions:

- Non-Standard Dimensions: In many cases, standard flanges may not fit the specific dimensions required by a particular application. Customized non-standard flanges address this challenge by being precisely engineered to match the unique dimensions, ensuring a perfect fit and compatibility with existing equipment. This flexibility allows industries to overcome space constraints and maintain the integrity of their systems.

- Aggressive Environments: Certain industries, such as chemical processing or mining, operate in aggressive environments where standard flanges may be prone to corrosion or failure. Customized non-standard flanges offer the advantage of material selection tailored to withstand corrosive chemicals, extreme temperatures, or abrasive substances. By choosing suitable alloys or coatings, these flanges provide long-lasting durability and performance in challenging environments.

- Specialized Applications: Customized non-standard flanges play a crucial role in specialized applications where standard flanges may not have the required features or capabilities. For example, industries utilizing cryogenic processes, high-vacuum systems, or specialized connection requirements rely on custom flanges to ensure proper sealing, maintain pressure integrity, and meet specific safety standards. Customization allows for the integration of features such as cryogenic seals, vacuum-rated flange faces, or unique connection methods tailored to the application’s needs.

These case studies illustrate how customized non-standard flanges have successfully solved unique challenges in various industries. By understanding the specific requirements and collaborating closely with our clients, we can develop tailored solutions that address complex applications, overcome limitations, and ensure optimal performance and reliability. Customization allows industries to find the perfect balance between functionality, efficiency, and safety, ultimately driving their success.

VI. Conclusion

In this blog post, we have explored the world of customized non-standard flanges and their significance in specialized applications. We discussed the advantages of customizing flanges to meet specific requirements, highlighting the importance of precision and accuracy in the production process. Throughout the customization journey, several key stages were addressed, including initial consultation, engineering, and design, material selection, manufacturing, testing and inspection. We also presented real-life case studies that demonstrate the successful implementation of customized flanges to solve unique challenges across different industries.

At YANHAO, we take pride in our expertise and commitment to delivering high-quality customized flanges. Our experienced engineers collaborate closely with customers to understand their project requirements, ensuring effective communication and tailored solutions. We utilize advanced software and tools for engineering and design, enabling us to develop precise and optimized flange designs. With state-of-the-art production facilities, we employ various manufacturing techniques and implement stringent quality control measures to guarantee the reliability and performance of our products.

If you are seeking flange solutions that address your specific needs and requirements, we encourage you to consider the possibilities of customization. Non-standard flanges offer a range of benefits, including enhanced functionality, improved efficiency, and long-term cost-effectiveness by minimizing downtime and maintenance. By partnering with YANHAO, you can leverage our expertise and experience in delivering customized flanges that meet your unique application challenges. Contact us today to discuss your project and explore the vast potential of customized flange solutions.

Remember, when it comes to non-standard flanges, customization is the key to unlocking optimized performance and ensuring a perfect fit for your applications. Trust YANHAO to be your reliable partner in delivering tailor-made flange solutions that exceed your expectations and drive your success.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.