Welcome to our comprehensive guide on flanges and their various types. Flanges play a crucial role in connecting pipes and ensuring the efficiency and safety of pipeline systems. In this blog, we will delve into the different types of flanges and their specific applications. As experts in the field, Hebei Yanhao Pipeline Equipment Co., Ltd. (Yanhao) takes pride in delivering high-quality flange products and exceptional customer service. With our extensive knowledge and expertise, we aim to provide you with a deeper understanding of flanges while highlighting Yanhao as a trusted and reliable China flange manufacturer. Let’s explore the world of flanges together and uncover the excellence that Yanhao brings to the industry.

The Purpose and Function of Flanges

The primary purpose of flanges is to connect pipes and components in a secure and leak-proof manner. Flanges act as a connecting interface between two sections of pipe or between a pipe and a component, such as a valve, pump, or fitting.

Flanges provide several important functions in pipeline connections. Firstly, they serve as a connection point, allowing pipes and components to be joined together. This enables the efficient flow of fluids or gases through the system.

Secondly, flanges create a strong and rigid joint that can withstand high pressure and temperature conditions. The flange connection prevents the pipes from separating or leaking under the stress of fluid or gas flow.

Furthermore, flanges facilitate the disassembly and maintenance of pipeline systems. By using bolts to secure the flanges, the joint can be easily dismantled for inspections, repairs, or component replacements.

In terms of creating a secure and leak-proof joint, flanges employ a gasket between the flange faces. The gasket acts as a sealing material to prevent the escape of fluids or gases and to maintain the integrity of the system. When the flange is bolted together, the compressive force applied to the gasket ensures a tight seal, thus preventing leakage.

The ability of flanges to provide a secure and leak-proof joint is crucial in industries such as oil and gas, petrochemicals, and chemical processing, where the containment and transport of fluids or gases are of utmost importance. Flanges play a significant role in maintaining the reliability and safety of pipeline systems.

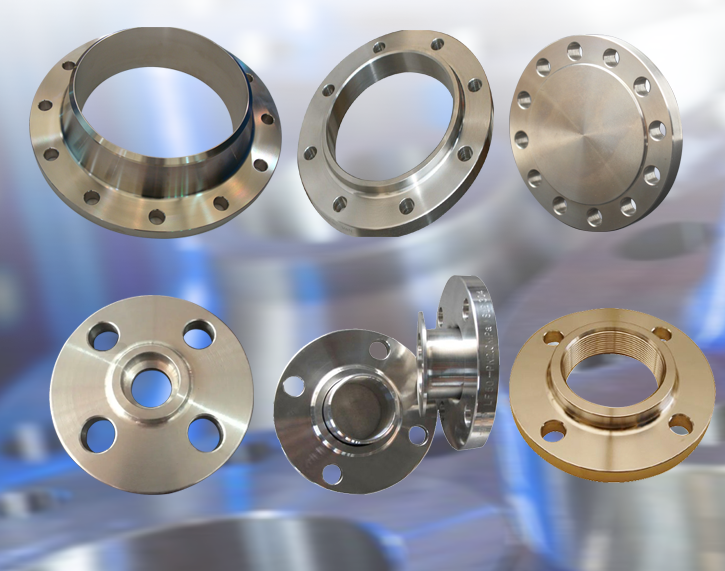

Types of Flanges and Their Applications

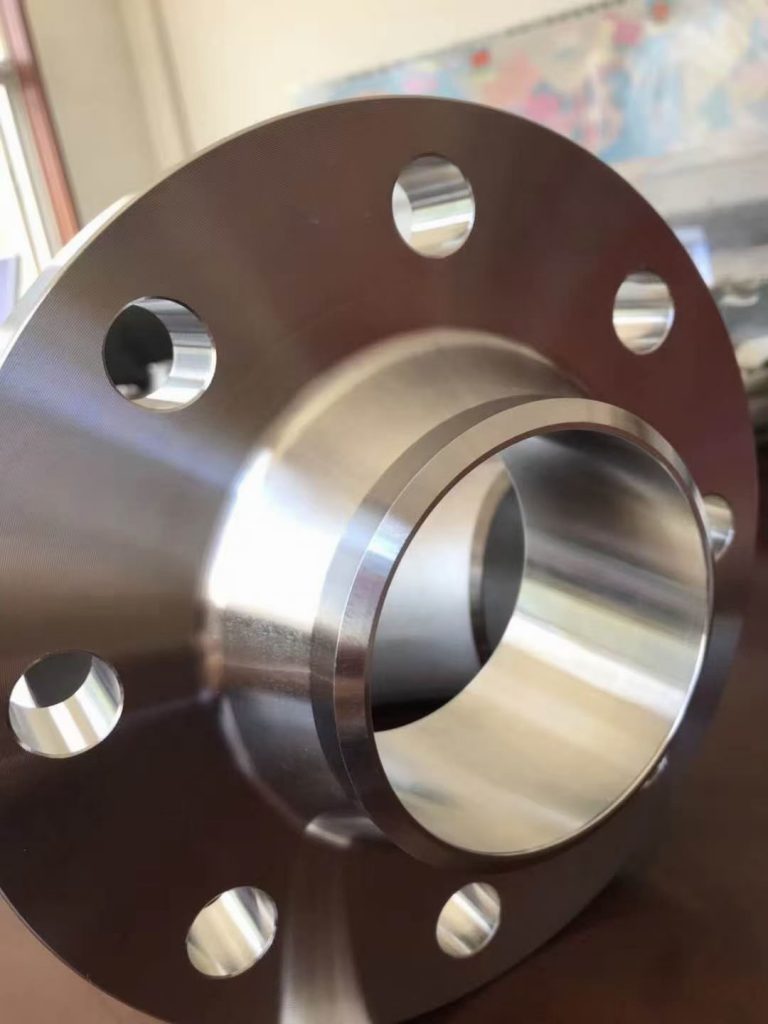

a. Weld Neck Flanges:

- Weld neck flanges have a tapered hub and a long neck that provides reinforcement to the joint. This design reduces stress concentrations and provides a smooth transition from the flange face to the pipe.

- The advantages of weld neck flanges include high durability, excellent resistance to mechanical stresses and vibrations, and superior leak resistance.

- Weld neck flanges are commonly used in critical and high-pressure applications due to their ability to withstand high pressure and provide a strong and secure connection.

- In the oil and gas industry, weld neck flanges are used in pipelines, offshore platforms, and refineries. They are also utilized in the petrochemical industry for high-pressure and high-temperature applications, such as chemical processing plants and power generation facilities.

Weld neck flanges provide reliable and leak-proof connections, making them essential components in industries that require secure and durable flange connections under demanding conditions.

b. Slip-On Flanges:

- Slip-on flanges have a flat face and a slightly larger diameter than the pipe. They are designed for easy installation and alignment.

- One of the main benefits of slip-on flanges is their simplicity and ease of installation. They slide over the pipe and are then welded in place, creating a strong and secure connection.

- Slip-on flanges are commonly used in low-pressure applications where the system does not require the high strength and pressure resistance of other flange types.

- Industries, where slip-on flanges are commonly employed, include water supply systems, HVAC (heating, ventilation, and air conditioning) systems, fire protection systems, and low-pressure fluid handling systems.

- Slip-on flanges provide convenience in applications where frequent maintenance or disassembly is required, as they can be easily removed and reinstalled without damaging the pipe or the flange.

The simplicity and ease of installation of slip-on flanges make them a preferred choice in industries that require efficient and cost-effective connections for low-pressure systems.

c. Socket Weld Flanges:

- Socket weld flanges have a socket or bore that is designed to fit over the pipe end. They have a recessed area where the pipe is inserted, and then it is welded on both the outer and inner sides of the flange.

- The unique feature of socket weld flanges is their ability to provide a smooth flow path, as the socket reduces turbulence and eliminates the need for a separate pipe end preparation.

- Socket weld flanges are commonly used in small bore piping systems, typically with pipes ranging from 1/2″ to 4″ in diameter. They offer an effective connection solution for small-diameter pipes.

- Socket weld flanges are also suitable for high-pressure environments, as the socket and weld joint provide a strong and reliable connection that can withstand elevated pressures.

- Industries that commonly use socket weld flanges include chemical processing, oil and gas, power generation, pharmaceuticals, and food processing. They are often employed in piping systems handling high-pressure fluids, steam, or gases.

Socket weld flanges offer a compact and reliable connection for small bore piping systems, making them an ideal choice for industries that require secure and leak-tight connections in high-pressure environments.

Other Types of Flanges

a. Blind Flanges:

- Blind flanges are solid disks used to close or seal off the end of a pipe or a vessel. They are mainly used when it is necessary to close a pipe or an opening temporarily or permanently.

- Blind flanges play a crucial role in isolating sections of a piping system, preventing the flow of fluids or gases to a particular area.

- They are often used in piping systems where future expansion is anticipated. In such cases, blind flanges are installed at the end of a pipeline to allow for potential future connections or branches to be made without the need for major modifications or shutting down the entire system.

- The blind flanges can be easily removed whenever a connection is required in the future, allowing for convenient access to the pipeline without affecting the overall integrity of the system.

- Industries that frequently use blind flanges include oil and gas, chemical processing, water treatment, and construction. Blind flanges provide a reliable solution for closing off areas in piping systems, facilitating maintenance, repair, and future expansion needs.

b. Lap Joint Flanges:

- Lap joint flanges consist of two components – a flat face flange and a separate stub end. The flange has a flat face while the stub end has a lap joint ring or flared end.

- The unique design of lap joint flanges allows for easy alignment and rotation of pipes during installation or maintenance. The stub end slides into the flange, providing flexibility in the positioning and alignment of the connected pipes.

- Lap joint flanges are often used in systems where frequent dismantling or replacement of pipes is required. They allow for easy disassembly without needing to remove the entire flange, making maintenance or modifications more convenient.

- Lap joint flanges are particularly suitable for applications involving piping systems that require regular cleaning or inspection, as they can be easily disconnected and reassembled without the need for specialized tools.

- Industries that commonly utilize lap joint flanges include food and beverage, pharmaceuticals, chemical processing, and plumbing and irrigation systems.

Lap joint flanges offer flexibility in installation and provide ease of disassembly, making them ideal for industries that require frequent maintenance, cleaning, or modification of piping systems.

c. Threaded Flanges:

- Threaded flanges have internal threads on the bore that allow them to be screwed onto the external threads of pipes or fittings. They create a secure and leak-proof connection through threaded engagement.

- Threaded flanges are commonly used in low-pressure applications where the system does not require high strength or pressure resistance. They are suitable for systems operating at or below 150 psi.

- The installation of threaded flanges is relatively simple and straightforward. They can be easily screwed onto the pipe or fitting using manual tools such as a wrench or pipe wrench.

- Threaded flanges eliminate the need for welding or specialized equipment, which can make them a cost-effective and convenient choice for certain applications.

- Industries, where threaded flanges are commonly employed, include plumbing, irrigation systems, low-pressure fluid handling, and small-scale industrial applications.

- It is important to note that threaded connections may not be as strong as other types of flange connections, so they may not be suitable for high-pressure or critical applications where a stronger and more secure joint is required.

Threaded flanges offer ease of installation, making them a practical option for low-pressure applications. However, they may not be suitable for higher-pressure systems or applications that require a stronger and more reliable connection.

Factors to Consider While Selecting Flanges

A. Pressure rating and temperature requirements:

It is crucial to select flanges that have the appropriate pressure rating and temperature capabilities for the specific application. Flanges should be able to withstand the maximum pressure and temperature conditions of the system without compromising safety or performance.

B. Materials and corrosion resistance:

The material of the flange must be compatible with the fluid or gas being transported and the environment it will be exposed to. Consider factors such as corrosion resistance, chemical resistance, and mechanical properties to ensure the longevity and reliability of the flange.

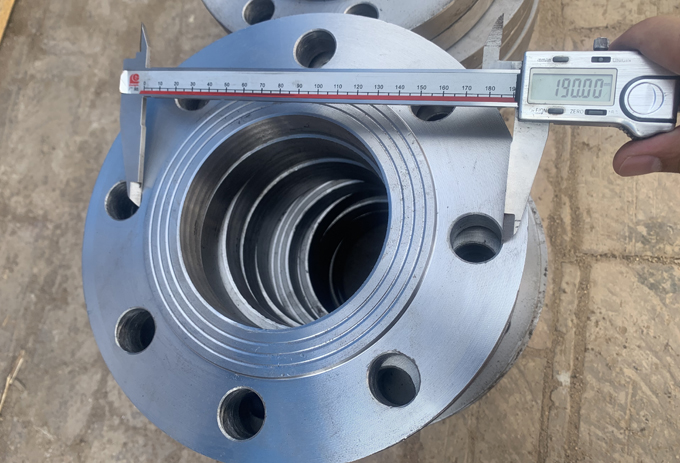

C. Size and dimension considerations:

Flanges should be selected based on the pipe size and dimensions of the piping system. Ensure that the flange size matches the pipe size to achieve a proper fit and connection. Additionally, consider factors such as flange thickness, face-to-face dimensions, and bolt-hole patterns for seamless integration with the system.

D. Compatibility with piping system:

Flanges need to be compatible with the overall piping system, including other components such as valves, fittings, and pumps. Ensure that the flange type, face type, and connecting methods align with the requirements of the system for easy assembly, disassembly, and maintenance.

Other factors to consider may include cost, industry standards, certifications, and any specific requirements or regulations in the application field.

Advantages of Choosing Yanhao Flanges

- Extensive Experience and Expertise: Yanhao Flanges has a wealth of experience and expertise in manufacturing flanges. We have a deep understanding of flange design and manufacturing processes, ensuring that they deliver high-quality products.

- Wide Range of High-Quality and Custom Flange Products: Yanhao offers a comprehensive range of high-quality flange products that cater to various industries and applications. We have the capability to provide custom-designed and manufactured flanges based on specific customer requirements, ensuring optimal performance and fit.

- Commitment to Superior Customer Service: Yanhao Flanges is dedicated to providing excellent customer service. Our professional team excels in order processing, timely delivery, and responsive after-sales support. Customers can rely on them for timely and satisfactory solutions to their needs.

Choosing Yanhao Flanges means selecting a manufacturer with extensive experience, expertise, and commitment to delivering high-quality flange products and superior customer service.

By carefully evaluating these factors, one can choose the most suitable flanges that meet the specific needs of the project, ensure a secure and leak-proof connection, and optimize the overall performance and efficiency of the piping system.

Installation and Maintenance of Flanges

A. Proper Installation Procedures for Flanges:

- Clean the flange and pipe surfaces thoroughly to ensure a proper seal.

- Align the flanges properly before installing and ensure that the bolt holes match up correctly.

- Apply an appropriate gasket material between the flange faces to prevent leakage.

- Tighten the bolts evenly and in a crisscross pattern to distribute the load evenly and achieve a uniform seal.

- Use a torque wrench to tighten the bolts to the recommended torque specified by the flange manufacturer.

- Inspect the installed flange for any signs of leaks or misalignment, and make adjustments as necessary.

B. Maintenance Tips for Flanges:

- Regularly inspect flanges for signs of leaks, corrosion, or damage.

- Clean the flange surfaces and remove any debris or buildup that may affect the sealing performance.

- Replace gaskets periodically or as needed to ensure a proper seal.

- Check the tightness of bolts and retorque if necessary, especially after any system modifications or repairs.

- Lubricate flange bolts to prevent rust and ensure easy removal in the future if needed.

- Train personnel in proper handling and maintenance procedures for flanges to avoid any mishandling that could lead to damage or leaks.

C. Common Issues and Troubleshooting:

- Leaks: Assess the gasket condition and replace it if damaged. Ensure proper tightening of bolts and inspect for any misalignment that could cause leakage.

- Bolt Breakage: Check for over-tightened bolts or incorrect torque values. Replace broken bolts and retorque the flange to the recommended specifications.

- Corrosion: Address any corrosion issues promptly. Clean the affected areas and apply corrosion-resistant coatings or consider using corrosion-resistant materials for future installations.

- Misalignment: Inspect flanges for proper alignment and connection. If misalignment is detected, realign the flanges and ensure a proper seal.

- Warping or Damage: Replace any flanges that are warped or damaged as they may compromise the integrity of the system.

- Vibrations or Loosening: Use lock washers or thread-locking compounds to prevent the loosening of bolts due to vibrations. Regularly check and retighten bolts if necessary.

Regular inspection, proper installation, and timely maintenance are essential to ensure the performance and integrity of flanges in a piping system. Prompt troubleshooting and addressing any issues will help prevent leaks, damage, and system failures.

Conclusion

In summary, this comprehensive guide has provided an overview of what a flange is and its various types. It explained that flanges are mechanical joints used to connect pipes, valves, and other equipment in a piping system. Different designs, such as weld neck, slip-on, socket weld, threaded, and blind flanges, offer specific applications and advantages.

The importance of proper installation and maintenance of flanges for optimal performance was emphasized. Following correct installation procedures, conducting regular maintenance, and promptly addressing common issues is crucial to prevent leaks, corrosion, misalignment, and other problems that can compromise the integrity of the system.

When considering flange options, it is worth exploring Chinese manufacturers like YANHAO that offer high quality, experience, competitive pricing, and manufacturing capabilities. Choosing such manufacturers can provide cost-effective solutions while ensuring high-quality flanges.

In conclusion, this guide serves as a valuable resource for understanding what a flange is, its various types, and key considerations related to their installation and maintenance in a piping system.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.