Welcome to our blog: “How to choose the correct flange type between ANSI and ASME flanges?” In this blog post, we will guide you on how to make the right choice when it comes to selecting a flange type between ANSI and ASME standards. As a part of Hebei Yanhao Pipeline Equipment Co., Ltd., we bring our expertise and experience to provide you with comprehensive insights into industry standards, application tips, and our company’s product offerings. In this blog, we will delve into the key differences, and factors to consider, and provide you with expert recommendations. Join us on this journey to make informed decisions with the help of our knowledge and expertise.

Explanation of ANSI and ASME standards for flanges

ANSI Standards for Flanges:

The American National Standards Institute (ANSI) sets the standards for flanges in the United States. ANSI standards ensure the uniformity and interchangeability of flanges across different manufacturers. Some key aspects of ANSI standards for flanges include:

- Dimensions: ANSI standards specify the dimensions of flanges, including the outer diameter, inner diameter, bolt hole sizes, and overall thickness. These dimensions ensure compatibility between ANSI flanges produced by different manufacturers.

- Pressure Ratings: ANSI standards define the pressure ratings for flanges based on the material and design. The pressure classes range from 150 to 2500, indicating the maximum allowable pressure the flange can withstand.

- Materials: ANSI standards provide guidelines for the selection of suitable materials for flanges based on the application requirements. Common materials used for ANSI flanges include carbon steel, stainless steel, and alloy steel.

ASME Standards for Flanges:

The American Society of Mechanical Engineers (ASME) establishes standards for various mechanical components, including flanges. ASME standards are more specific and are widely recognized globally. Some key aspects of ASME standards for flanges include:

- Design: ASME standards provide detailed specifications for flange design, ensuring optimal performance and safety. This includes factors such as the flange face, gasket design, and bolting requirements.

- Pressure-Temperature Ratings: ASME standards define the pressure-temperature ratings for flanges, indicating the maximum pressure and temperature combinations that the flange can handle safely.

- Manufacturing and Testing: ASME standards outline the manufacturing practices and testing procedures to ensure the quality and reliability of flanges. This includes processes like heat treatment, dimensional control, and non-destructive testing.

Both ANSI and ASME standards play a crucial role in ensuring the integrity and compatibility of flanges in various applications. It is essential to consider these standards when selecting flanges to ensure proper functionality and adherence to industry regulations. Consulting with industry experts, like YANHAO, can provide guidance on choosing the right flange type based on specific requirements.

Importance of selecting the correct flange type for specific applications

Selecting the correct flange type for specific applications is of utmost importance for several reasons:

- Secure and Reliable Connection: Flanges form a crucial connection between pipes, valves, and other equipment in a piping system. Choosing the correct flange type ensures a secure and reliable connection, preventing leaks, system failures, and potential safety hazards. Proper sealing and alignment provided by the correct flange type contribute to the overall integrity and efficiency of the system.

- Pressure and Temperature Resistance: Different applications require flanges to withstand varying levels of pressure and temperature. Selecting the correct flange type with appropriate pressure and temperature ratings ensures that the system can handle the desired operating conditions without compromising safety or performance. Failure to adhere to the correct flange type specifications can result in catastrophic consequences, such as equipment damage or even accidents.

- Material Compatibility: The choice of flange type should consider compatibility with the materials used in the piping system. Different fluids, chemicals, or gases flowing through the system may have specific requirements in terms of material compatibility. Selecting a flange type made from the appropriate material prevents corrosion, chemical reactions, and potential contamination, ensuring the longevity and reliability of the system.

- Industry Compliance: Industries often have specific standards and regulations that dictate the type of flange to be used in different applications. It is essential to select the correct flange type that complies with industry standards to meet regulatory requirements, maintain safety, and ensure conformity with best practices.

- Installation and Maintenance Ease: Choosing the correct flange type ensures easier installation and maintenance of the piping system. Proper fitment, alignment, and standardization provided by the correct flange type simplify installation procedures, reduce downtime during maintenance, and facilitate future modifications or expansions to the system.

selecting the correct flange type for specific applications is crucial for ensuring a secure and reliable connection, handling pressure and temperature requirements, maintaining material compatibility, complying with industry regulations, and facilitating ease of installation and maintenance. It is important to consider these factors and consult with experts like YANHAO to make informed decisions and optimize the performance of the piping system.

Understanding the Key Differences

Key Differences between ANSI and ASME Flanges

- Standards Organizations: ANSI is the American National Standards Institute, a nonprofit organization that develops and publishes voluntary consensus standards. ASME is the American Society of Mechanical Engineers, a professional association that sets codes and standards for mechanical devices and systems.

- Scope: ANSI standards for flanges focus on ensuring uniformity and interchangeability among flange manufacturers in the United States. ASME standards cover a wider range of mechanical components and are recognized globally.

- Dimensions: ANSI flange dimensions are standardized and typically follow the ASME B16.5 standard. ASME flanges can have variations in dimensions due to the different pressure classes and flange types specified in ASME B16.5 and other ASME standards.

- Pressure Ratings: ANSI flanges have pressure ratings ranging from 150 to 2500. ASME flanges also have various pressure classes, such as 150, 300, 600, 900, 1500, and 2500, indicating the maximum allowable pressure the flange can withstand. The pressure ratings for ASME flanges are usually higher than ANSI flanges.

- Materials: ANSI and ASME flanges can be made from various materials such as carbon steel, stainless steel, and alloy steel. However, ASME standards provide more extensive guidelines on material specifications and selection for flanges based on the specific application requirements.

Impact on Performance and Compatibility

- Interchangeability: ANSI flanges follow standardized dimensions, ensuring interchangeability among different manufacturers. This promotes compatibility and ease of maintenance or replacement in piping systems. ASME flanges may have slight variations in dimensions based on specific applications, which may limit interchangeability to some extent.

- Pressure Handling: ASME flanges generally have higher pressure ratings, allowing them to handle more demanding applications. Selecting the correct flange type with the appropriate pressure rating is crucial to ensure safe and reliable performance.

- Material Compatibility: The variations in material specifications provided by ASME standards enable a better selection of flanges that are compatible with the fluid or gas being transported. This ensures resistance to corrosion, chemical reactions, and potential contamination, enhancing the longevity and performance of the system.

- Global Recognition: ASME standards are widely recognized globally, making ASME flanges more suitable for international projects or applications where compliance with international standards is required.

Understanding these key differences between ANSI and ASME flanges helps in making informed decisions when selecting flanges for specific applications. It ensures compatibility, performance, and adherence to the appropriate industry standards. Consulting with industry experts, such as YANHAO, can provide further guidance on selecting the most suitable flange type based on specific project requirements.

Factors to Consider When Choosing Flange Types

When choosing flange types, there are several important factors to consider:

- Flange Application and Industry Requirements: Consider the specific application and industry in which the flange will be used. Different industries may have specific requirements or standards that need to be met. For example, the oil and gas industry may require flanges that are suitable for high-pressure and high-temperature environments.

- Pressure and Temperature Specifications: Determine the pressure and temperature requirements of your application. Flanges are designed to handle specific pressure ratings and temperature ranges. It is crucial to select a flange that can withstand operating conditions to ensure the safety and integrity of the system.

- Material Compatibility and Corrosiveness: Consider the type of fluid or gas being transported through the piping system and its corrosiveness. Different materials offer various levels of resistance to corrosion and chemical reactions. Select a flange material that is compatible with the fluids or gases to prevent degradation and leaks.

- Size and Configuration Considerations: Determine the size and configuration requirements of the flange. Flanges are available in different sizes and configurations to match the dimensions and specifications of the piping system. Ensure that the flange size and configuration align with the pipe size and flange connection type.

- Standards and Certifications: Check if there are any industry-specific standards or certifications that the flange needs to adhere to. Examples of widely used standards for flanges include ASME B16.5, ANSI B16.5, and API 6A. Compliance with these standards guarantees the flange’s quality, performance, and interchangeability.

- Cost Considerations: Consider the cost of the flange, including the material, manufacturing, and maintenance costs. While it’s important to find a flange that meets the required specifications, it’s also essential to consider the budgetary constraints and the cost-effectiveness of the chosen flange.

By considering these factors, you can select the most suitable flange type for your specific application, ensuring optimal performance, reliability, and safety of the piping system. Consulting with flange manufacturers or industry experts can provide further guidance based on your specific requirements.

Navigating Flange Sizing: Industry Standards and Their Application

Industry standards play a crucial role in determining the sizing of flanges as they provide guidelines and specifications for various aspects of flange design and dimensions. Two widely used standards for flanges are ANSI and ASME.

ANSI (American National Standards Institute) standardizes the dimensions and specifications for various flange types in the United States. ANSI B16.5 is the most commonly used standard for pipe flanges and flanged fittings. It covers dimensions, tolerances, materials, pressure ratings, and facings of flanges for use in a wide range of industries.

ASME (American Society of Mechanical Engineers) sets codes and standards for mechanical devices and systems, including flanges. ASME B16.5 is similar to ANSI B16.5, covering the same aspects of flange design and dimensions. ASME B16.47 covers larger pipe flanges for high-pressure, high-temperature applications.

When comparing ANSI and ASME sizing standards, it is essential to note that they are very similar and have minor differences in terminology and some specification details. The key is to understand the specific requirements of your application and select the appropriate standard accordingly.

Important factors to consider in flange sizing include:

- Bore Diameter: This refers to the inside diameter of the flange that matches the pipe’s outside diameter. Flange sizes typically correspond to pipe sizes, and it is crucial to select the correct bore diameter to ensure a proper fit and efficient flow.

- Bolt Circle: The bolt circle is the diameter of the imaginary circle passing through the centers of the bolt holes in the flange. It determines the spacing and arrangement of the bolts that secure the flange to the mating flange or equipment. The bolt circle dimensions should match the flange size and configuration requirements.

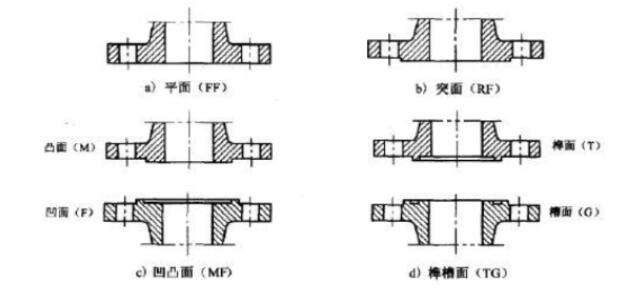

- Flange Face Finish: The flange face finish refers to the contact surface between the flange and gasket. Different flange faces, such as flat faces (FF) and raised faces (RF), have specific finish requirements, such as smoothness and roughness. The flange face finish affects the sealing capability and compatibility with gaskets.

Considering these factors ensures that the flange size and dimensions are suitable for the piping system and meet industry standards. It is also important to consult specific standards, such as ANSI B16.5 or ASME B16.5, for detailed specifications and guidelines on flange sizing and dimensions.

About YANHAO

YANHAO is a renowned company specializing in manufacturing and supplying a wide range of products. we have built a strong reputation in the industry for our commitment to quality, innovation, and customer satisfaction. Here are some key aspects of YANHAO:

- Expertise and Experience: Operating in the “Flange and Pipe Fittings Town,” With years of operation, we have accumulated years of experience and expertise in the field. we have garnered a deep understanding of the market and customer needs. Whether it’s their manufacturing techniques, product development, or industry knowledge, YANHAO is well-equipped to deliver outstanding solutions.

- Diverse Product Portfolio: YANHAO offers a diverse range of products to cater to various industries and applications. From flanges to other related products, we ensure a comprehensive selection to meet their customers’ requirements. our products are known for their durability, precision, and reliability.

- Quality Assurance: YANHAO places great importance on maintaining high-quality standards. we have strict quality control processes in place to ensure that every product leaving their facilities meets industry regulations and customer expectations. YANHAO’s commitment to quality is evident in its satisfied customer base.

- Competitive Pricing: YANHAO’s advantageous location in Mengcun contributes to its ability to offer competitive pricing. offers competitive pricing due to its industrial chain advantage, raw material advantage, and streamlined production processes. The close proximity to raw material suppliers, combined with a well-established industrial chain, allows YANHAO to optimize production costs and offer cost-effective solutions. Additionally, their efficient production processes enable them to minimize waste and maximize resource utilization, further enhancing their price competitiveness, all while maintaining high product quality.

- Customer Focus: YANHAO is dedicated to providing exceptional customer service. we prioritize understanding our customers’ specific needs and strive to offer personalized support and solutions. Our friendly and knowledgeable team is readily available to address any inquiries, provide technical advice, and assist throughout the purchasing process.

- Continuous Improvement: YANHAO believes in continuous improvement and staying at the forefront of their industry. we invest in research and development to enhance their products and manufacturing processes. By embracing innovation, YANHAO ensures they remain competitive and deliver cutting-edge solutions.

Whether you are looking for reliable products, technical expertise, or excellent customer service, YANHAO is well-equipped to meet your requirements. Don’t hesitate to reach out to them for more information or to discuss how they can cater to your specific needs.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.