I. Introduction

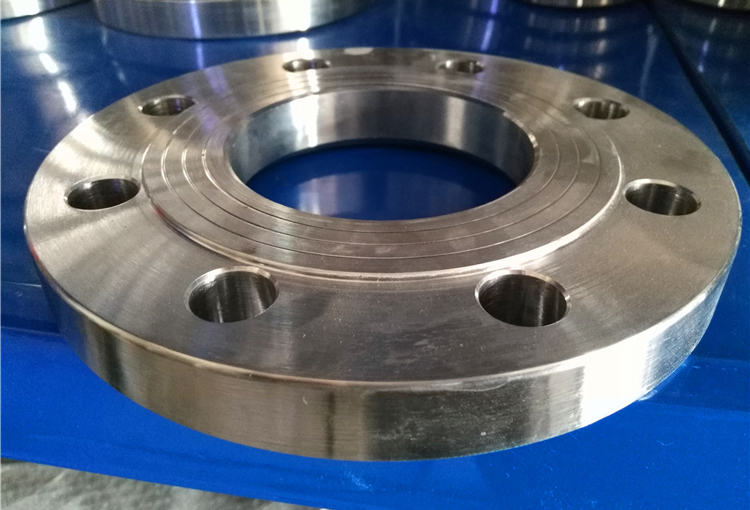

Accurately measuring the ID (inner diameter) of a flange is a critical step in ensuring the proper fit and functionality of piping systems. A flange with an incorrect inner diameter can result in leaks, system failures, and costly repairs. Therefore, it is essential for readers to understand the importance of precise measurements and the relevance of finding a reliable source for high-quality flanges.

At YANHAO, we recognize the significance of accurate flange measurements. As a leading flanges supplier, we prioritize precision and quality in our manufacturing processes. Our flanges undergo rigorous testing and inspection to ensure they meet the required specifications and function flawlessly in piping systems.

II. Understanding Flange Terminology and Components

To accurately measure the inner diameter (ID) of a flange, it is essential to understand the terminology and components associated with flanges. Here is an overview:

- Inner Diameter (ID): The inner diameter refers to the measurement of the circular opening inside the flange. It is one of the key dimensions that determine the compatibility of the flange with other piping components.

- Outer Diameter (OD): The outer diameter is the measurement of the flange’s circular edge. It is typically larger than the inner diameter and helps determine the size of the flange.

- Bolt Circle Diameter (BCD): The bolt circle diameter is the measurement of the circle formed by the centers of the bolt holes on the flange. It determines the spacing and arrangement of bolts used to connect the flange to other components.

- Flange Facing: The flange facing is the smooth area on the flange surface that comes in direct contact with the gasket. It provides a sealing surface for the gasket to prevent leakage.

- Flange Thickness: The flange thickness refers to the measurement of the material’s thickness comprising the flange. It determines the structural strength and compatibility of the flange with the piping system.

A proper understanding of these flange components and their associated terminology is crucial when measuring the ID accurately. By familiarizing yourself with these terms, you will have a better grasp of the necessary measurements and can ensure a seamless fit and functioning of the flange in your piping system.

In the next section, we will explore the various methods used to measure the ID of a flange. Whether you have a standard or custom flange, these techniques will help you achieve precise measurements for optimal performance.

III. Methods for Measuring the ID of a Flange

A. Direct Measurement Methods

When it comes to accurately measuring the inner diameter (ID) of a flange, there are several direct measurement methods that can be employed. Let’s explore two common techniques:

- Calipers: Calipers are versatile tools that can be used to measure the ID of a flange quickly. Here’s how to use calipers effectively:

- Select a pair of digital or vernier calipers appropriate for the flange size.

- Gently open the calipers and position the measuring arms inside the flange.

- Ensure that the calipers are parallel to the flange faces.

- Gradually close the jaws until they make contact with the flange surfaces.

- Take note of the displayed measurement and record the ID. Calipers provide a relatively accurate measurement of the flange ID, although the precision may vary depending on the quality and type of calipers used.

2. Inside Micrometer: Inside micrometers – also known as internal micrometers or bore micrometers – offer a higher level of precision for measuring the ID of a flange. Here’s how to use an inside micrometer:

- Ensure the micrometer is properly calibrated and set to zero.

- Insert the measuring rods into the flange, positioning them opposite each other.

- Gradually increase the tension on the micrometer’s thimble until the measuring rods make contact with the flange surfaces.

- Take note of the measurement displayed on the micrometer’s scale.

- Repeat the process at multiple points to ensure accuracy, especially if the flange’s ID is not completely uniform.

Inside micrometers provide more precise measurements compared to calipers due to their specialized design for measuring internal diameters. They are commonly used in applications that require tight tolerances and accurate dimensional control.

By employing these direct measurement methods, you can ensure precise and reliable measurements of the ID for your flanges. In the next section, we will explore additional techniques for measuring the ID of a flange indirectly.

(Note: It is essential to follow the manufacturer’s guidelines and instructions when using any measurement tools to ensure accurate results.)

B. Indirect Measurement Methods with Tools

In addition to direct measurement methods, there are indirect measurement techniques that can be used to measure the inner diameter (ID) of a flange. Here are a couple of commonly used tools:

- Tape Measure: A tape measure is a simple and commonly available tool that can be used to estimate the ID of a flange. Here’s how to use a tape measure for this purpose:

- Place one end of the tape measure flat against the flange face.

- Wrap the tape measure around the inside circumference of the flange, ensuring it follows the circular path.

- Take note of the measurement where the end of the tape meets the tape itself.

- Divide the measured circumference by π (pi) to calculate the approximate ID. While a tape measure can provide a rough estimate of the flange ID, it may not offer the same level of accuracy as direct measurement methods. The flexibility of the tape and potential variations in user technique can introduce errors and limitations to the measurement. Therefore, it is advisable to use more precise measurement methods whenever possible.

2. Flange Dimension Tables: Flange dimensions for common flange sizes are often standardized and readily available in reference tables. These tables provide the ID, outer diameter, thickness, and other relevant dimensions for various flange types and sizes.

- Identify the flange type and size you are working with.

- Refer to the appropriate dimension table, which can be found in engineering handbooks or flange manufacturer catalogs.

- Locate the corresponding flange size and note the documented ID value. Using standardized dimension tables can be a convenient and reliable method for determining the flange ID, especially for commonly used flange sizes. However, it is crucial to ensure you are using accurate and up-to-date reference tables specific to the flange standards and specifications you are working with.

By utilizing these indirect measurement methods with tools, you can estimate the flange ID when direct measurement techniques are not readily available or practical. However, for precise and critical applications, it is generally recommended to rely on direct measurement methods or seek the assistance of professionals with specialized equipment.

C. Advanced Techniques for Complex Flange Designs

For non-standard or complex flange designs that cannot be easily measured using traditional methods, advanced measurement techniques such as Coordinate Measuring Machines (CMM) and Laser Scanning can provide high accuracy and detailed measurements. Let’s explore these advanced techniques:

- Coordinate Measuring Machines (CMM): CMMs are highly accurate and versatile measurement devices used for dimensional inspection and geometrical analysis. Here’s how CMMs can be used to measure complex flanges:

- The flange is securely mounted on the CMM’s measurement table, ensuring it is positioned accurately.

- The CMM utilizes a combination of contact and non-contact measurement tools, such as touch probes, optical sensors, or laser scanners.

- The CMM systematically moves the measurement tools across the flange surface, collecting numerous data points.

- The collected data is analyzed by specialized software, generating a detailed and precise 3D representation of the flange geometry, including the ID. CMMs provide accurate measurements even for complex flange designs with irregular shapes, internal features, or intricate contours. They can capture a vast amount of data, ensuring comprehensive inspection and evaluation of the flange dimensions.

2. Laser Scanning: Laser scanning technology is a non-contact method that captures detailed 3D measurements of the flange surface using laser beams. The capabilities of laser scanning for measuring intricate flange designs include:

- The laser scanner is positioned at various angles and orientations around the flange, covering its entire surface.

- The laser beam sweeps across the flange, measuring the distance between the scanner and the surface at each point.

- The reflected data is collected and processed by specialized software, generating a highly accurate 3D model of the flange, including the ID. Laser scanning ensures precise measurements of complex flange designs, including flanges with multiple grooves, indentations, or non-uniform shapes. It provides detailed visualizations, facilitating thorough analysis and dimensional verification.

Both CMMs and laser scanning technology offer advanced capabilities for accurately measuring non-standard or complex flange designs. These techniques provide highly detailed and reliable results, making them particularly valuable for critical applications that require stringent dimensional control or when manufacturing unique and customized flange designs.

It is important to note that these advanced techniques may require specialized equipment and expertise. Therefore, engaging professionals with relevant experience or utilizing technical service providers can ensure accurate and effective measurements for complex flange designs.

IV. The Importance of Accurate Flange Measurement and Quality Assurance

Accurate flange measurement is of utmost importance in ensuring proper fit, alignment, and functionality of flanges in piping systems. Here’s why precise flange measurements are significant:

- Fit and Alignment: Flanges act as connectors between different sections of piping systems, ensuring a secure and leak-free joint. Accurate measurements ensure that flanges are sized correctly and have the necessary dimensional compatibility with adjoining components. Proper fit and alignment of flanges help establish a tight and reliable connection, preventing leakage and maintaining system integrity.

- Sealing Integrity: Flanges rely on gaskets or seals to create a fluid-tight seal between the mating surfaces. Precise flange measurements ensure that the gasket sits correctly within the flange groove and is compressed evenly when the flanges are bolted together. Proper sealing integrity is crucial to prevent leaks, which can lead to loss of fluid, environmental contamination, or even safety hazards.

- System Performance and Efficiency: Accurate flange measurements contribute to the overall performance and efficiency of piping systems. A properly aligned and tightly sealed flange reduces pressure losses, promotes smooth fluid flow, and minimizes energy wastage. It ensures that the system operates as intended, without unnecessary leaks, vibrations, or inefficiencies.

The consequences of using incorrectly measured flanges can be significant and detrimental:

- Leaks and Fluid Loss: Using flanges that do not fit properly or have incorrect dimensions can lead to leaks. Fluid leakage not only results in material wastage but can also cause environmental pollution and safety hazards. Leaks in hazardous or corrosive fluid systems may have severe consequences, including equipment damage, downtime, and increased maintenance costs.

- System Failures: Incorrectly measured flanges can compromise the overall structural integrity and functionality of the piping system. Inadequate fit and alignment can result in stress concentration, leading to premature fatigue, cracks, or even catastrophic failure. System failures can disrupt operations, cause significant damage, and pose safety risks to personnel and surrounding infrastructure.

- Cost Overruns and Repercussions: Inaccurate flange measurements can have financial implications in terms of rework, replacement, and increased maintenance. Rectifying issues arising from incorrect flange measurements may require shutting down operations, replacing flanges, and modifying the system, which can lead to project delays, cost overruns, and customer dissatisfaction.

To mitigate these risks, proper quality assurance measures should be implemented throughout the flange manufacturing, installation, and inspection processes. This includes adherence to industry standards, utilizing accurate measurement techniques, conducting thorough inspections, and employing skilled professionals. Regular maintenance and periodic re-evaluation of flanges are also crucial to ensure ongoing performance, reliability, and safety in piping systems.

In summary, accurate flange measurement is essential for the proper fit, alignment, and functionality of flanges in piping systems. Incorrectly measured flanges can lead to leaks, system failures, increased costs, and safety hazards. Therefore, ensuring precise flange measurements and robust quality assurance practices are vital for the integrity and efficiency of piping systems.

V. Our Expertise in Flange Measurement and Manufacturing

At YANHAO, we pride ourselves on being a trusted and reputable manufacturer of high-quality flanges. With years of experience in the industry, we have established ourselves as experts in producing accurately measured flanges with strict quality control processes.

Our commitment to precision starts with our advanced manufacturing facilities, which are equipped with state-of-the-art machinery and cutting-edge technology. This enables us to consistently produce flanges with precise measurements, ensuring a proper fit and alignment in piping systems.

To maintain the highest standards of quality, we have implemented stringent quality control processes at every stage of production. Our team of skilled engineers and inspectors meticulously inspect each flange, carefully verifying its dimensions and ensuring it meets all necessary specifications. This rigorous quality assurance process guarantees that every flange leaving our facility meets the highest industry standards.

As a reliable source for flanges, we understand the importance of customer satisfaction. Customer needs and requirements are at the forefront of our operations, and we strive to provide flanges that not only meet but exceed their expectations. We work closely with our clients, offering technical support, customized solutions, and timely delivery to ensure a seamless and successful partnership.

Our expertise in flange measurement and manufacturing extends across a wide range of industries, including oil and gas, petrochemicals, power generation, and more. Our track record of delivering high-quality flanges for various applications has established us as a trusted supplier in the market.

If you’re in need of accurately measured flanges for your piping systems, trust YANHAO to provide the highest quality products and an unmatched level of customer service. We are committed to meeting your flange requirements with precision, reliability, and utmost professionalism.

VI. Conclusion

In conclusion, accurate flange measurement is crucial for the proper functioning and efficiency of piping systems across various industries. YANHAO, as a trusted and reputable manufacturer, excels in producing precisely measured flanges with strict quality control processes.

We highlighted our expertise in manufacturing high-quality flanges, emphasizing our commitment to precision and customer satisfaction. Our advanced manufacturing facilities, coupled with stringent quality control processes, ensure that every flange meets the highest industry standards.

By choosing YANHAO as your supplier, you can have confidence in the reliability and precision of our flanges. We are dedicated to meeting your specific requirements and exceeding your expectations. Whether you are in the oil and gas, petrochemical, or power generation industry, we have the expertise to provide you with the highest-quality flanges for your piping systems.

Make YANHAO your trusted partner for accurate flange measurement and manufacturing. Contact us today to discuss your flange needs and experience our unmatched level of professionalism and customer service.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.