Introduction

API flanges play a crucial role in numerous industries, facilitating the secure connection of piping systems and ensuring the safe and efficient transportation of fluids and gases. In this comprehensive guide, we will delve into the world of API flanges, exploring their definition, importance, and various applications.

At YANHAO, we take great pride in our expertise and dedication to manufacturing high-quality API flanges. As a China flange manufacturer, YANHAO (Hebei Yanhao Pipeline Equipment Co., Ltd.) has built a reputation for delivering reliable and innovative flange solutions to our clients.

In this guide, we aim to provide you with a comprehensive understanding of API flanges, their industry standards, and specifications, as well as the significance of proper flange sizing. We will also highlight YANHAO’s commitment to producing top-notch API flanges that meet or exceed industry standards.

By the end of this guide, you will be equipped with the knowledge and insights necessary to make informed decisions when it comes to API flanges. Choose YANHAO for all your flange needs and experience the exceptional quality and customer satisfaction we strive to deliver.

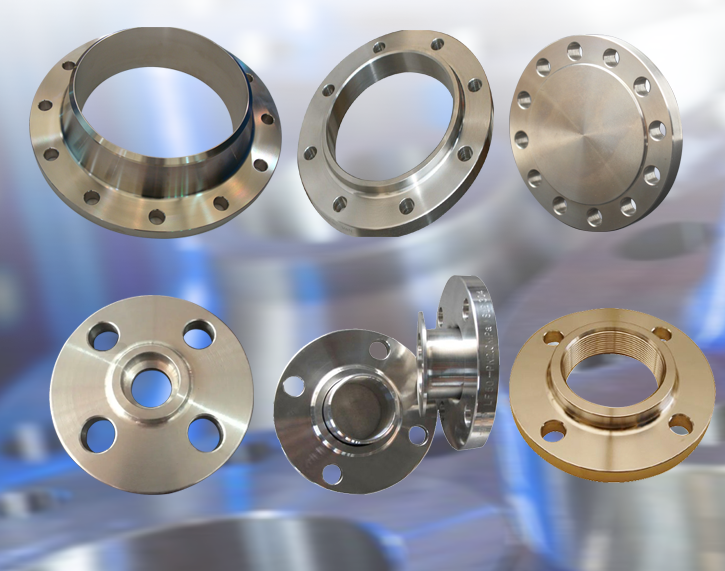

API Flange Types and Functions

A. Slip-On Flanges:

Slip-on flanges feature a slightly larger diameter than the pipe and are slipped over the end of the pipe before being welded in place. They are best suited for low-pressure and non-critical applications.

B. Weld Neck Flanges:

Weld neck flanges have a long tapered hub and are ideal for high-pressure and high-temperature applications. The long hub provides reinforcement and reduces stress concentration at the base of the flange.

C. Blind Flanges:

Blind flanges are used to close the end of a pipeline or vessel. They are solid discs with no center hole, making them effective in isolating a section of the piping system.

D. Threaded Flanges:

Threaded flanges have internal threads that allow them to be screwed onto the pipe. They are commonly used in low-pressure applications and can be easily installed and removed without welding.

E. Socket Weld Flanges:

Socket weld flanges have a socket for the pipe to fit into, allowing for a smooth flow path. They are well-suited for small-diameter piping systems and high-pressure applications.

F. Lap Joint Flanges:

Lap joint flanges consist of two parts – a stub end and a backing flange. The stub end is welded to the pipe, and the backing flange is left loose. They are used in systems that require rotational alignment or easy assembly and disassembly.

G. Orifice Flanges:

Orifice flanges are used in flow measurement applications. They have a concentric hole or an eccentric hole to accommodate an orifice plate, which can measure the flow rate of the fluid passing through the pipeline.

H. Spectacle Blind Flanges:

Spectacle blind flanges are a combination of a blind flange and a spacer ring. They are used to temporarily or permanently block off sections of a pipeline.

These are some of the commonly used API flanges. Each type has its unique design and function, and it is important to choose the right flange based on the specific requirements of the application.

API Flange Standards and Specifications

API (American Petroleum Institute) sets industry standards and specifications for various aspects of the oil and gas industry, including API flanges. Here are some of the important API standards and specifications related to API flanges:

- API 6A: API 6A provides specifications for wellhead and Christmas tree equipment, including flanges used in this equipment. It covers the design, testing, and performance requirements for flanges used in high-pressure and high-temperature applications.

- API 16A: API 16A covers the specifications for drilling and production of wellhead equipment, including flanges. It outlines the design, dimensions, material requirements, and testing procedures for these flanges. API 16A flanges are designed for critical applications that require high-pressure and high-temperature resistance.

- API 17D: API 17D provides specifications for subsea production systems, including flanges used in these systems. It covers the design, dimensions, material requirements, and testing procedures for subsea flanges. API 17D flanges are designed to withstand the demanding conditions of subsea operations, such as deepwater oil and gas extraction.

These API standards ensure that the flanges manufactured and used in the oil and gas industry meet specific requirements for performance, safety, and reliability. It is essential to comply with these standards to ensure compatibility, interchangeability, and consistent quality of API flanges across the industry.

API Flange Sizing

API flanges come in a range of sizes to accommodate different piping systems. The sizing of API flanges is typically specified using a nominal pipe size (NPS) and a pressure rating class.

The nominal pipe size refers to the approximate inner diameter of the pipe that the flange will be used with. Common NPS sizes for API flanges include 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″, 5″, 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 24″, and larger.

The pressure rating class indicates the maximum pressure the flange can withstand. API flanges commonly come in pressure rating classes such as 150, 300, 600, 900, 1500, and 2500. The pressure rating class is typically determined based on the material, design, and intended application of the flange.

It’s important to note that API flanges are designed to be used in accordance with industry standards such as API 6A or API 16A. These standards provide detailed specifications for the design, materials, and testing of flanges used in oil and gas applications. When selecting an API flange, it is crucial to ensure that it meets the required specifications for your specific piping system and operating conditions.

Benefits and Application of API Flanges

API flanges offer several benefits and find wide applications in the oil and gas industry. Here are some of the key benefits and applications of API flanges:

Benefits:

- High Pressure and Temperature Capabilities: API flanges are designed to handle high-pressure and high-temperature applications, making them suitable for critical operations in the oil and gas industry. They provide reliable sealing and prevent leakage under demanding operating conditions.

- Industry Standardization: API flanges adhere to specific standards and specifications set by the American Petroleum Institute, ensuring compatibility and interchangeability across different manufacturers and projects. This standardization facilitates efficient procurement, installation, and maintenance processes.

- Robust Construction: API flanges are manufactured using high-quality materials and undergo rigorous testing to ensure their strength, durability, and performance. They are designed to withstand harsh operating conditions, including corrosive environments, abrasive media, and extreme temperatures.

- Wide Range of Flange Types: API standards cover various flange types, including slip-on, weld neck, blind, threaded, socket weld, lap joint, orifice, and spectacle blind. This variety allows for flexibility in selecting the most suitable flange type for the specific application.

Applications:

- Oil and Gas Exploration and Production: API flanges are extensively used in wellhead and Christmas tree equipment, subsea production systems, drilling rigs, and other applications related to oil and gas extraction. They provide a secure connection between various components and piping systems, allowing for a smooth flow of fluids and gases.

- Pipeline Systems: API flanges play a crucial role in pipeline systems, facilitating connection, disconnection, and maintenance activities. They provide a reliable and leak-proof joint between pipeline sections and are used at key points, such as pump stations, valve stations, and metering stations.

- Refining and Petrochemical Industry: API flanges are commonly used in refineries, petrochemical plants, and chemical processing facilities. They are employed in equipment such as reactors, heat exchangers, separators, and storage tanks, ensuring the safe and efficient operation of these industrial units.

- Offshore and Subsea Applications: API flanges designed for subsea environments are used in offshore drilling rigs, floating production units, subsea pipelines, and other underwater installations. These flanges withstand the challenging conditions of deepwater operations, including high pressures, corrosive seawater, and extreme temperatures.

Overall, API flanges are crucial components in the oil and gas industry, providing a reliable and standardized means of connecting, sealing, and supporting various equipment and piping systems.

YANHAO’s Competitive Advantages in API Flange Production

YANHAO possesses several competitive advantages that distinguish it in the field of API flange production:

- Expertise and Experience: YANHAO has a team of highly skilled engineers and technicians with extensive knowledge and experience in API flange production. This expertise allows the company to consistently deliver high-quality products that meet industry standards and customer requirements.

- State-of-the-Art Facilities: YANHAO has invested in modern manufacturing facilities with advanced equipment and technologies. These facilities enable efficient and precise production processes, resulting in superior-quality API flanges.

- Quality Materials: YANHAO sources materials from trusted suppliers and conducts thorough inspections to ensure their quality and suitability for API flange production. The use of high-grade materials contributes to the durability and reliability of YANHAO’s API flanges.

- Customization Capabilities: YANHAO understands that different applications may require specific flange designs and specifications. With its flexible manufacturing capabilities, YANHAO can provide customized API flanges tailored to meet unique customer needs.

- Competitive Pricing: Despite its commitment to quality, YANHAO offers competitive pricing for its API flanges. The company aims to deliver value to customers by combining high-quality products with affordable pricing.

YANHAO stands out as a reliable and customer-focused API flange manufacturer. Our dedication to quality, customer satisfaction, and competitive advantages in production make us a strong choice for those in need of API flanges. By choosing YANHAO, customers can be assured of receiving high-quality products, excellent service, and customized solutions that meet their specific requirements.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.