Introduction:

Welcome to our blog post on the topic “How do Chinese flange prices compare to those of other countries?” In this article, we will delve into the world of flange manufacturing and explore the competitive pricing offered by Chinese manufacturers. As Hebei Yanhao Pipeline Equipment Co., Ltd., a leading company in the field of pipeline equipment, we aim to provide you with valuable insights into the flange industry, while highlighting our expertise and commitment to quality.

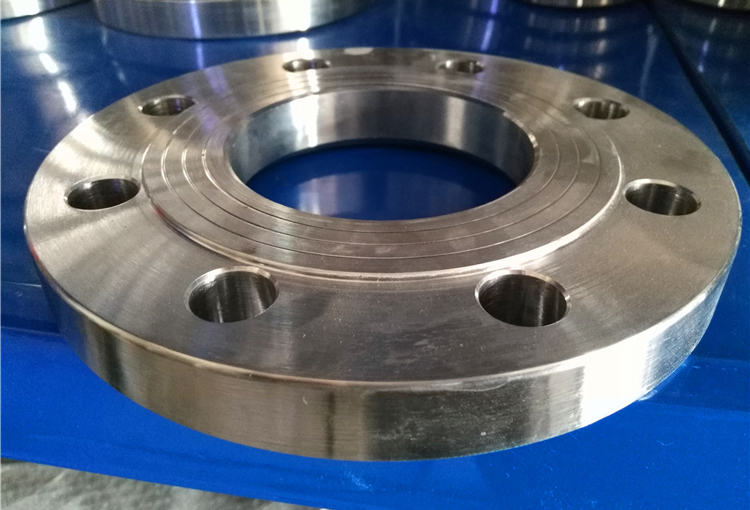

Flanges are essential components in various industries, including oil and gas, chemical, shipbuilding, pharmaceuticals, power generation, and paper manufacturing. They play a crucial role in connecting pipes and ensuring the smooth flow of fluids or gases. As such, it is imperative to source flanges that meet international quality standards while keeping costs reasonable.

China has emerged as a dominant force in the flange manufacturing industry, offering competitive prices without compromising on quality. In this article, we will explore the reasons behind the affordability of Chinese flanges and compare them with those of other countries, particularly the United States, Germany, and Japan.

Additionally, we will address any concerns regarding the quality and compliance of Chinese flanges, showcasing our dedication to upholding strict quality control procedures and meeting international standards. Our commitment to expertise, integrity, and customer satisfaction has garnered widespread acclaim, making us the preferred choice for numerous industries.

So, join us as we uncover the advantages of Chinese flange pricing, the strengths of Hebei Yanhao Pipeline Equipment Co., Ltd., and our vision to expand globally, particularly in the European and American markets. Discover how our competitively priced flanges can elevate your pipeline projects, without compromising on quality or reliability.

Let’s dive in and explore the intriguing world of flange pricing, comparing China’s offerings with the rest of the world.

Overview of the Chinese Flange Industry

China’s flange industry holds significant importance in the global market due to its vast production capabilities and reputation as a major player in the flange manufacturing sector. Chinese manufacturers have become renowned for their ability to produce high-quality flanges at competitive prices, making them an attractive choice for industries worldwide.

One of the key advantages of Chinese flange manufacturers is their lower production costs. China benefits from economies of scale, allowing for efficient mass production and reduced manufacturing expenses. This cost advantage is particularly beneficial for larger orders, where customers can enjoy substantial savings compared to other countries.

Furthermore, the extensive supply chain in China contributes to the competitiveness of its flange manufacturers. The country has a robust network of raw material suppliers, making it easier for manufacturers to source high-quality materials at competitive prices. This ensures consistent access to the necessary resources for flange production, further driving down costs.

Chinese manufacturers also have access to renowned steel suppliers. China is home to some of the world’s largest steel producers, allowing flange manufacturers to procure high-quality steel at favorable rates. The availability of quality steel contributes to the durability and reliability of Chinese flanges, making them a preferred choice in various industries.

Additionally, China’s flange industry benefits from continuous technological advancements and innovation. Manufacturers invest heavily in research and development to improve production processes, enhance product quality, and meet international standards. This commitment to innovation has further solidified China’s position as a prominent player in the global flange market.

In conclusion, China’s flange industry holds great significance due to its production capabilities, competitive pricing, and commitment to quality. The lower production costs, extensive supply chain, and access to renowned steel suppliers contribute to the advantages of Chinese flange manufacturers. These factors make Chinese flanges a compelling choice for industries worldwide, cementing China’s reputation as a major player in the global market.

Comparative Analysis of Flange Prices

When comparing Chinese flange prices with those of other major manufacturing countries like the United States, Germany, and Japan, it becomes evident that China offers competitive pricing advantages. Several cost factors contribute to the affordability of Chinese flanges, including favorable production conditions, lower labor costs, and efficient supply chain management.

In terms of production conditions, China benefits from economies of scale. The country’s large manufacturing base allows for mass production, resulting in lower production costs per unit. This advantage enables Chinese manufacturers to offer more competitive prices compared to countries with smaller production capacities.

Furthermore, China has a significantly lower labor cost compared to countries like the United States, Germany, and Japan. This wage disparity allows Chinese manufacturers to produce flanges at a lower cost, reducing the overall price for customers. While China has witnessed a gradual increase in labor costs over the years, it still maintains a relative advantage in this aspect.

Efficient supply chain management is another cost factor that contributes to the competitive pricing of Chinese flanges. China boasts a well-developed and integrated supply chain network, allowing manufacturers to source raw materials, such as steel, at competitive prices. The availability and affordability of raw materials directly influence the production costs of flanges. China’s robust supply chain ensures consistent access to high-quality materials at favorable rates, helping to keep prices competitive.

It is important to note that while Chinese flange prices are generally more affordable, quality remains a crucial consideration. Chinese manufacturers, like Hebei Yanhao Pipeline Equipment Co., Ltd., prioritize maintaining strict quality control measures and adhering to international standards. This commitment ensures that customers receive flanges that meet their required specifications, guaranteeing the performance and reliability of the components.

In comparison, flange prices in countries like the United States, Germany, and Japan may be higher due to various factors. These include higher production costs, stricter labor regulations, and higher overhead expenses. While these countries have their own advantages in terms of technological advancements and reputation for precision engineering, the higher costs associated with production and labor can translate into higher prices for flanges.

In conclusion, Chinese flange prices are frequently more competitive compared to those of other major manufacturing countries. Factors such as favorable production conditions, lower labor costs, and efficient supply chain management contribute to the affordability of Chinese flanges. However, it is essential to consider quality assurance when evaluating pricing differences, as reliable performance and adherence to international standards remain crucial in the flange industry.

Quality Assurance and Compliance

Concerns regarding the quality of Chinese flanges and adherence to international standards are important considerations for customers. However, it is crucial to note that many Chinese flange manufacturers, including our company, place a strong emphasis on maintaining strict quality control procedures and ensuring compliance with international standards.

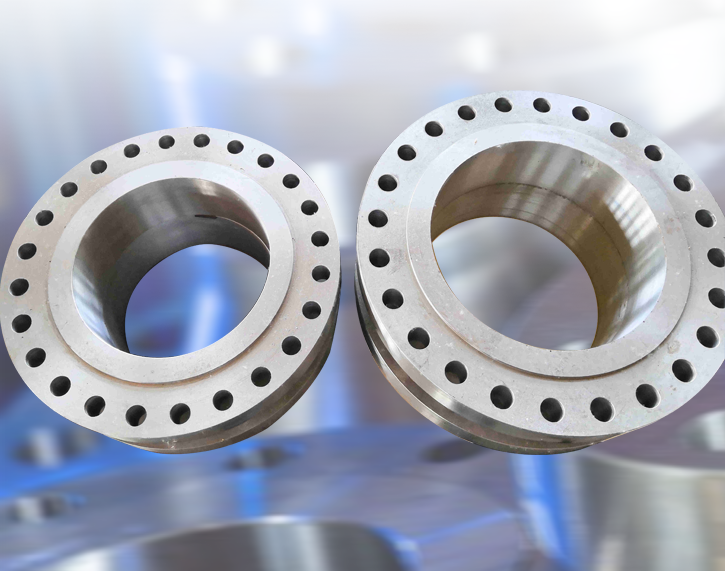

Firstly, our company is committed to implementing robust quality control measures at every stage of the manufacturing process. This begins with careful selection and inspection of raw materials, ensuring that only high-quality materials are used in the production of flanges. Our quality control team conducts rigorous inspections and tests throughout the manufacturing process to ensure that all products meet the required specifications.

In terms of standards compliance, our company adheres to internationally recognized standards such as ASTM (American Society for Testing and Materials), ASME (American Society of Mechanical Engineers), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). We are fully aware of the importance of meeting these standards to ensure the performance, safety, and reliability of our flange products.

To guarantee the quality and accuracy of our flanges, we utilize state-of-the-art testing equipment. This includes advanced non-destructive testing methods such as ultrasonic testing and magnetic particle inspection, as well as dimensional measurement equipment. These testing procedures enable us to detect any potential defects or irregularities in the flanges and ensure that they meet or surpass industry standards.

Furthermore, our commitment to quality is demonstrated by our investment in research and development. We continuously strive to improve our manufacturing processes, explore new technologies, and enhance the performance of our flanges. This dedication allows us to stay updated with the latest advancements in the industry and ensures that our products consistently meet the evolving needs and requirements of our customers.

We understand the significance of quality assurance and compliance in the flange industry. Therefore, our company places the utmost importance on maintaining strict quality control procedures, adhering to international standards, and investing in state-of-the-art testing equipment. These efforts are aimed at delivering flanges of exceptional quality, reliability, and performance to our customers, ensuring their satisfaction and trust in our products.

Expertise and Trustworthiness

As a leading flange manufacturer, our company takes pride in our extensive expertise and experience in the industry. With years of operation and a dedicated team of professionals, we have established ourselves as a trusted and reliable provider of flanges for diverse industries.

One of our key strengths lies in our ability to serve a wide range of industries. Our flanges have been utilized in industries such as oil and gas, petrochemicals, power generation, water treatment, construction, and more. This diverse experience has honed our skills and knowledge in understanding the specific requirements and challenges of each industry. We continuously strive to provide tailored solutions that meet the unique needs of our customers.

Our commitment to honesty, integrity, and customer satisfaction is at the core of our business values. We firmly believe in building long-term partnerships with our customers, and this trust and loyalty are reflected in the repeat business we receive. Many of our customers have been relying on our flanges for years, benefiting from their exceptional quality, durability, and performance.

Furthermore, our company takes great care in fulfilling our promises to customers. We understand that deadlines and project timelines are crucial in many industries, and we strive to meet our commitments without compromising quality or reliability. Our dedicated customer service team ensures smooth communication, prompt responses, and efficient order processing, further enhancing our customers’ experience with us.

To solidify our expertise and trustworthiness, we have also earned widespread acclaim in the industry. Our flanges have received positive feedback and recognition from clients around the globe. This acknowledgment is a testament to our commitment to delivering top-notch products and exceptional service.

In conclusion, our company’s expertise and experience in the flange industry, along with our commitment to honesty, integrity, and customer satisfaction, set us apart from our competitors. We have served diverse industries, earned long-term partnerships, and received widespread acclaim. We continue to build on our strengths and strive to exceed the expectations of our customers, solidifying our position as a trusted and reliable provider of high-quality flanges.

Conclusion:

As a Chinese flange manufacturer, we recognize the significant advantage of Chinese flanges in terms of affordability and competitive pricing. Our products offer relative affordability without compromising on quality, catering to the market’s capacity to bear costs. This enables us to meet customers’ demands for high-quality products while maintaining competitive pricing.

Our company is dedicated to providing outstanding products and services. We rigorously control the quality of our products, adhering to international standards and ensuring performance and reliability through advanced testing equipment. We continually invest in research and development to enhance manufacturing processes and technological capabilities, ensuring our customers receive the best possible flange products.

We aspire to expand our global footprint and deliver exceptional value to customers in the European and American markets. We welcome interested customers to contact us via email to further discuss partnerships and solutions.

We sincerely look forward to collaborating with you and providing you with high-quality Chinese flange products and services. Whether you have requirements in any industry or region, we are ready to be your preferred partner. Contact us and let us create a brighter future together.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.