Chinese flanges play a significant role in the global market due to their widespread use in various industries, including oil, chemical, shipbuilding, pharmaceuticals, and more. As the world’s largest manufacturing hub, China’s flange industry has a considerable production capacity and market share. Understanding the factors that affect Chinese flange prices is crucial for businesses and buyers looking for cost-effective and reliable suppliers. In this blog, we will explore the key factors influencing Chinese flange prices, providing valuable insights into the dynamics of this market.

Overview of the Chinese Flange Industry

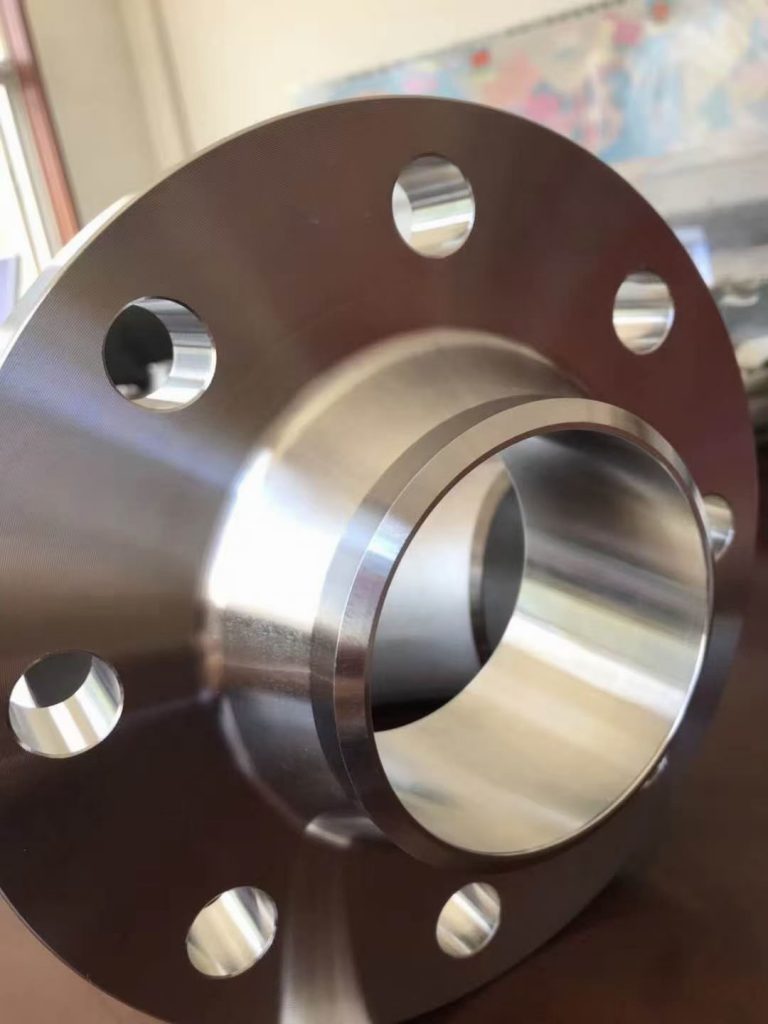

The Chinese flange industry is a prominent sector within the country’s manufacturing landscape. With its vast production capacity and strong market presence, China is one of the leading producers and exporters of flanges worldwide.

Flanges hold immense importance in various sectors, serving as essential components in critical piping systems. In the oil and gas industry, flanges are used to connect pipelines and facilitate fluid transfer. In the chemical industry, they play a crucial role in ensuring the safe transportation of corrosive substances. Flanges are also extensively utilized in shipbuilding, pharmaceuticals, power generation, water treatment, and many other sectors.

China’s flange industry benefits from a robust manufacturing infrastructure and skilled workforce. The country’s production capacity allows for the efficient and cost-effective production of flanges in large quantities. This, in turn, contributes to China’s significant market share in the global flange trade.

With a diverse range of flange types and specifications, Chinese manufacturers are equipped to meet the specific requirements of different industries. Whether it is standard flanges or custom-designed ones, China’s flange industry has the capability to produce high-quality products that comply with international standards and technical specifications.

The reliability and performance of Chinese flanges have gained recognition and trust from global buyers. This has resulted in strong market demand for Chinese flanges, further solidifying China’s position as a major player in the international flange industry.

Factors Influencing Chinese Flange Prices

a. Raw Material Costs:

Raw material costs are one of the most significant factors influencing Chinese flange prices. Flanges are typically made from materials like stainless steel, alloy steel, and carbon steel, and the prices of these raw materials can fluctuate based on market conditions.

Fluctuations in stainless steel prices, for example, can significantly impact the overall cost of manufacturing flanges. Stainless steel is a common material used for flanges due to its corrosion-resistant properties, making it particularly important in industries like oil, chemical, and pharmaceuticals. Changes in the price of stainless steel can directly affect the cost of producing flanges, thereby influencing their selling prices.

Similarly, the prices of alloy steel and carbon steel, which are also commonly used in flanges, can have a significant impact on overall manufacturing costs. The availability and cost of these materials are affected by global supply and demand dynamics, geopolitical factors, and trade policies.

China, being a major steel-producing nation, plays a crucial role in the global steel market. The country’s prominent steel suppliers, such as Baosteel Group, Shougang Group, and Tianjin Steel Mill, have significant influence and hold a substantial market share. These steel suppliers provide raw materials to the Chinese flange industry, and any fluctuations in their pricing or availability can directly impact the production costs and ultimately the prices of Chinese flanges. It is essential to monitor the activities of these key steel suppliers and keep an eye on the market conditions to understand the potential impact on flange prices.

b. Manufacturing and Labor Costs:

One of the key advantages of China’s flange industry is its low manufacturing and labor costs. China has a vast manufacturing infrastructure, with a well-established supply chain and efficient production processes. This allows Chinese manufacturers to benefit from economies of scale, reducing production costs.

Low manufacturing costs in China are primarily a result of the country’s abundant resources, strong supplier networks, and advanced production technologies. These factors enable Chinese flange manufacturers to source materials and components at competitive prices, optimize production processes, and minimize wastage. As a result, they can offer cost-effective solutions to customers in the global market.

Furthermore, China’s labor costs are relatively low compared to many other countries. The availability of a vast pool of skilled and semi-skilled labor in China allows manufacturers to keep labor costs under control. This, combined with efficient production methods and machinery, helps to minimize overall production expenses.

The advantage of low manufacturing and labor costs contributes to the competitive pricing of Chinese flanges. Chinese manufacturers can offer competitive prices while maintaining high-quality standards, attracting customers from various industries worldwide. The ability to produce flanges at a lower cost allows them to meet the price expectations of buyers without compromising on product quality or performance.

Additionally, the cost advantages enable Chinese manufacturers to cater to both mass-market demand and customer requirements. The economic benefits derived from cost-efficiency can be passed on to customers in the form of competitive pricing, providing them with cost-effective solutions for their flange needs.

However, it is essential to note that while China’s low manufacturing and labor costs provide a competitive edge, the quality of products and compliance with international standards should also be considered when evaluating Chinese flanges.

c. Supply and Demand Dynamics:

Supply and demand dynamics play a crucial role in determining flange prices. When there is a high demand for flanges and a limited supply, prices tend to rise. Conversely, when the supply exceeds the demand, prices may decrease.

Flange demand is influenced by various factors, including the growth and expansion of industries that rely on flanges, such as oil, chemical, and shipbuilding. Economic development, infrastructure projects, and investment in energy and construction sectors also contribute to the demand for flanges. Changes in these factors can significantly impact flange demand, which, in turn, affects prices.

On the supply side, the production capacity of flanges, both domestically and internationally, influences the availability of flanges in the market. The capacity utilization of flange manufacturers, their ability to meet orders, and their production efficiency determine the supply levels. Any disruptions in the supply chain, such as raw material shortages, logistics challenges, or production issues, can result in supply imbalances and affect prices.

Global market conditions and geopolitical factors also play a vital role in shaping the supply and demand dynamics of flanges. For instance, trade policies, tariffs, and import/export regulations imposed by different countries can influence the flow of flanges across borders, impacting supply and prices. Geopolitical tensions, conflicts, or political instability in regions where flange production is concentrated can also disrupt supply chains and lead to fluctuations in prices.

Furthermore, changes in global oil prices and energy markets can have a significant impact on flange demand. Oil and gas projects, exploration activities, and investments in the energy sector drive the demand for flanges. Therefore, any fluctuations in these markets can directly affect the demand for flanges and subsequently impact their prices.

It is crucial for businesses in the flange industry to closely monitor global market conditions, industry trends, and geopolitical factors to anticipate changes in supply and demand dynamics. This awareness can help them make informed decisions regarding sourcing, production planning, and pricing strategies.

d. Quality and Technical Standards:

Adherence to international quality and technical standards is of utmost importance in the flange industry. Meeting these standards ensures that flanges are safe, reliable, and perform according to specifications. It also offers assurance to customers that they are purchasing high-quality products that have undergone rigorous testing and meet recognized industry benchmarks.

Compliance with international standards has several benefits for manufacturers and customers alike. Firstly, it ensures consistency and uniformity in the manufacturing process, helping to maintain product quality and performance across different batches and suppliers. Standards provide guidelines for material selection, design, manufacturing processes, and testing, ensuring that flanges are produced to the highest quality standards.

Secondly, adherence to international standards facilitates market access and facilitates trade. Many countries have regulations in place that require flanges to meet certain standards before they can be imported or used in specific industries. Compliance with these standards allows manufacturers to enter new markets and expand their customer base.

Compliance with international standards can also impact the pricing of Chinese flanges. Meeting these standards often requires additional investments in quality control measures, advanced manufacturing technologies, and testing facilities. These costs may be reflected in the pricing of the flanges. However, the higher price tag can be justified by the added value of quality, safety, and reliability that compliant flanges offer.

Additionally, compliance with standards enhances the reputation and credibility of Chinese flange manufacturers. Customers are more likely to choose suppliers who consistently adhere to recognized standards, as it demonstrates a commitment to quality and customer satisfaction. This can give Chinese manufacturers a competitive advantage, allowing them to command premium prices for their products.

Moreover, compliance with international standards can help mitigate risks and liabilities for both manufacturers and customers. Non-compliant flanges may suffer from performance issues, safety risks, and increased maintenance costs. By ensuring compliance, manufacturers can avoid potential legal issues and product recalls, protecting their reputation and minimizing financial losses.

In conclusion, adherence to international quality and technical standards is essential for the flange industry. It not only ensures the production of high-quality and safe products but also facilitates market access, increases credibility, and justifies competitive pricing. Chinese flange manufacturers that prioritize compliance with these standards can establish themselves as reliable and preferred suppliers in the global market.

Impact of Government Policies and Regulations

Government policies and regulations related to trade, environmental protection, and labor conditions can have a significant impact on flange prices. Let’s delve into three specific aspects: trade barriers, anti-dumping measures, and compliance with international standards.

- Trade Barriers:

Government-imposed trade barriers, such as tariffs, quotas, and import restrictions, can increase the cost of importing flanges and subsequently drive up prices. Higher import duties make it more expensive for foreign flange manufacturers to enter the domestic market, reducing competition and allowing domestic suppliers to charge higher prices. These barriers may be implemented to protect domestic industries, safeguard jobs, or promote economic growth. However, they can limit consumer choice and increase costs for businesses that rely on imported flanges. - Anti-dumping Measures:

Anti-dumping measures are regulations imposed to offset the impact of unfairly low-priced imported flanges that may harm domestic manufacturers. If foreign flange producers are found to sell their products below fair market value, anti-dumping duties or tariffs may be imposed to level the playing field. These measures aim to protect domestic manufacturers from unfair competition and preserve jobs. However, they can result in higher prices for imported flanges, as the additional duties increase the overall cost for customers. - Compliance with International Standards:

Government regulations often mandate compliance with international standards for flange manufacturers. These standards ensure product quality, safety, performance, and environmental impact. Manufacturers that invest in meeting these standards may experience higher production costs, which can be passed on to customers in the form of slightly higher prices. However, compliance with international standards enhances product quality, increases customer confidence, and expands market access, which can have a positive impact on demand and pricing in the long run.

In summary, government policies and regulations related to trade barriers, anti-dumping measures, and compliance with international standards can influence flange prices. Trade barriers may increase import costs and reduce competition, leading to higher prices. Anti-dumping measures can level the playing field for domestic manufacturers but may raise prices for imported flanges. Compliance with international standards may incur additional costs for manufacturers, which can be reflected in product pricing. Businesses operating in the flange industry need to stay informed about these policies and regulations to manage potential price implications and navigate the market effectively.

Fluctuations in Foreign Exchange Rates

Currency exchange rates have a significant impact on the pricing of Chinese flanges in the global market. Fluctuations in exchange rates can directly influence the cost of production, materials, and labor, ultimately affecting the export prices of Chinese flanges.

- Cost of Production:

Fluctuations in currency exchange rates can alter the cost of production for Chinese flanges. If the value of the Chinese yuan strengthens against other currencies, the cost of raw materials, components, and machinery imported from other countries may decrease. This can lead to lower production costs for Chinese flange manufacturers, enabling them to offer more competitive prices in the global market. Conversely, if the yuan weakens, the cost of imported materials may increase, potentially raising the export prices of Chinese flanges. - Competitive Position:

Currency fluctuations can impact the competitive position of Chinese flanges in the global market. If the Chinese yuan weakens, Chinese flanges may become more affordable compared to flanges produced in countries with stronger currencies. This can give Chinese manufacturers a competitive advantage, as customers in other countries can purchase Chinese flanges at relatively lower prices. On the other hand, if the yuan strengthens, Chinese flanges may become costlier, potentially eroding their competitiveness. - Trading Partner Economics:

Currency fluctuations also depend on the economic conditions of trading partners. If a country with significant import demand for Chinese flanges experiences economic growth, its currency may strengthen against the yuan. This can result in higher export prices for Chinese flanges in that specific market. Conversely, if a trading partner’s economy weakens, its currency may depreciate against the yuan. In this case, Chinese flanges may become relatively cheaper, potentially boosting demand in that market. - Hedging and Risk Management:

To mitigate the impact of currency fluctuations on export prices, Chinese flange manufacturers may engage in hedging and risk management strategies. Hedging involves using financial instruments to protect against adverse currency movements. Manufacturers may enter into contracts, such as forward contracts or currency options, to lock in exchange rates for future transactions. These strategies help in managing the uncertainty associated with currency fluctuations and stabilize export prices.

In summary, currency exchange rate fluctuations can significantly impact the pricing of Chinese flanges in the global market. Changes in exchange rates can influence production costs, competitive positioning, and demand for Chinese flanges. To manage currency risk, Chinese manufacturers often employ hedging strategies to stabilize export prices. Staying vigilant about currency movements and implementing effective risk management practices is crucial for Chinese flange manufacturers to adapt to changing market conditions and maintain competitiveness.

Conclusion

In conclusion, several key factors influence Chinese flange prices, including government policies and regulations related to trade, environmental protection, and labor conditions. Trade barriers and anti-dumping measures can impact import costs and competition, potentially leading to higher prices. Compliance with international standards may result in slightly higher production costs but can enhance product quality and market access in the long run.

Additionally, fluctuations in currency exchange rates play a significant role in determining the pricing of Chinese flanges in the global market. Changes in exchange rates can affect the cost of production, competitive positioning, and demand for Chinese flanges. Implementing hedging and risk management strategies can help mitigate the impact of currency fluctuations on export prices.

Considering these factors is crucial for global buyers and businesses seeking cost-effective and reliable flange suppliers in China. By understanding the impact of government policies, currency fluctuations, and regulatory compliance on pricing, buyers can make informed decisions and ensure they are working with reputable suppliers that meet their quality and cost requirements.

Furthermore, Yanhao is highlighted as an example of a low-priced and high-quality Chinese flange manufacturer. Buyers are encouraged to learn more and consult with Yanhao for their flange needs.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.