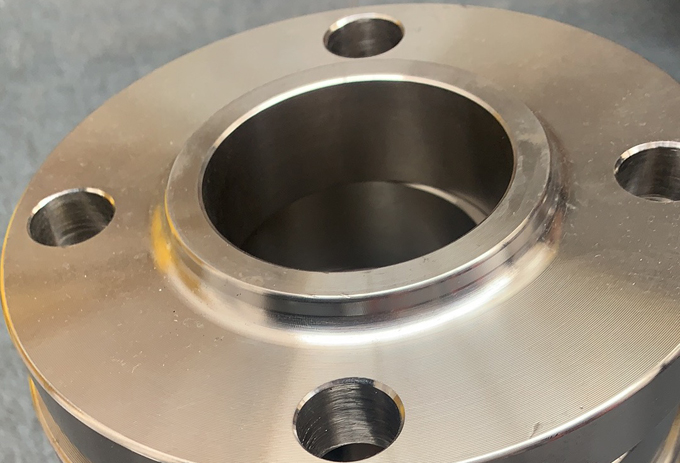

Flanges are used to connect pipes, valves, pumps, and other equipment together in a piping system. They provide a secure, leak-proof connection and allow for easy separation and maintenance of the components. Flanges are commonly used in industries such as oil and gas, chemical processing, water treatment, and power generation. They come in various sizes, materials, and types to suit different application requirements.

The application industries of flanges

Flanges are mainly used in the following industries:

- Oil and gas industry: Flanges are used to connect pipes, valves, pumps, and other equipment in drilling, production, and transportation processes to ensure the safe operation and transfer of fluids.

- Chemical industry: In chemical processes where handling and transportation of various chemicals and liquids are involved, flanges are used to connect pipelines and equipment to ensure the reliability and safety of fluid transfer and processing.

- Power generation industry: In power plants, substations, and transmission lines, flanges are used to connect pipelines and equipment such as boilers, steam turbines, and cooling systems for the transmission and control of medium flow.

- Water treatment industry: In water treatment facilities, flanges are used to connect various treatment units, filters, pumping stations, and valves to ensure the supply, treatment, and distribution of water.

- Pharmaceutical industry: In the pharmaceutical processes, flanges are required to connect and separate various equipment, reactors, and pipelines, providing a reliable connection method to ensure the quality and sanitary safety of drug production.

- Food and beverage industry: In food and beverage processing, flanges are used to connect processing equipment, storage tanks, conveying pipelines, etc., ensuring the hygienic standards of fluid processing, transport, and storage.

In addition to these industries, flanges are widely used in sectors such as shipbuilding, construction, heating and ventilation, wastewater treatment, and metallurgy to meet the specific requirements of different industrial fields.

The benefits of using flanges

There are several benefits of using flanges in various industrial applications. Some of the key benefits include:

- Reliable and Leak-proof Connections: Flanges provide a secure and leak-proof connection between pipes, valves, and other equipment. This ensures the integrity of the piping system and prevents any fluid or gas leakage, minimizing the risk of accidents or environmental damage.

- Easy Assembly and Disassembly: Flanges allow for easy assembly and disassembly of components in a piping system, making maintenance, repairs, and modifications more convenient. This facilitates faster turnaround times during maintenance and reduces downtime for industrial processes.

- Versatility and Flexibility: Flanges come in different sizes, materials, and types to suit various application requirements. They can be customized to meet specific needs and can be easily adapted for changes in the system or expansion of the piping network.

- Resistant to High Pressure and Temperature: Flanges are designed to withstand high pressure and temperature conditions, making them suitable for demanding industrial environments. They ensure the safe and efficient transfer of fluids, gases, and steam.

- Compatibility and Interchangeability: Flanges comply with industry standards and specifications, ensuring compatibility and interchangeability with other components and equipment. They can be easily connected to different types of flanges, valves, pumps, and fittings from various manufacturers.

- Enhanced System Integrity: Flanges provide stability and structural support to the piping system, reducing stress and vibration. This improves the overall system integrity, reliability, and longevity.

- Cost-Effective: Flanges offer a cost-effective solution for connecting and maintaining pipes and equipment. They require minimal welding and can be reused, reducing installation, replacement, and maintenance costs over time.

Overall, the use of flanges provides a range of benefits including secure connections, ease of maintenance, adaptability, durability, and cost-effectiveness, making them a preferred choice in many industrial applications.

Examples of Flange Applications

Here are some more detailed examples highlighting the specific applications of flanges in different industries, the before-and-after comparisons, and customer testimonials:

- Oil and gas industry:

At a petroleum extraction company, they were using standard flanges to connect oil well pipes and oil transmission pipelines. However, these flanges were prone to leakage under high pressure, causing production disruptions and safety hazards. After collaborating with their supplier, they switched to specially designed high-pressure flanges. Over the course of a year, they experienced zero leakages, greatly enhancing productivity and safety. The customer testimonial stated, “The new high-pressure flanges have solved our leakage issues, making our production line more reliable and efficient.” - Chemical industry:

At a chemical company, they were using standard flanges that were susceptible to corrosion in highly acidic and alkaline environments. This led to system damage and production downtime. By replacing the standard flanges with acid and alkali-resistant flanges, they were able to avoid corrosion issues, improving the stability and durability of their production line. The customer testimonial affirmed, “The acid and alkali-resistant flanges have enhanced the durability and reliability of our system, significantly reducing production line shutdowns for maintenance.” - Power industry:

At a power plant, they were using standard flanges to connect boilers and steam pipelines. However, these flanges were unable to provide optimal sealing performance in high-temperature and high-pressure environments, leading to energy waste and routine maintenance work. After switching to high-temperature and high-pressure flanges, the sealing effect improved significantly, reducing energy consumption and minimizing maintenance tasks. The customer testimonial remarked, “The new high-temperature and high-pressure flanges ensure the safe operation of our boilers and steam pipelines, greatly enhancing energy utilization efficiency.”

Conclusion

The above examples demonstrate the wide-ranging applications and importance of flanges in various industries. As a reputable flange manufacturer in China, YANHAO is dedicated to providing customers with a wide range of standard flanges, as well as customized solutions. We pride ourselves on delivering high-quality products, excellent post-sales support, and competitive pricing, which have earned us the trust and praise of our customers.

Whether you are in the petroleum, chemical, power, or other industries, we can provide tailored flange solutions to meet your specific needs. We prioritize product quality by using high-grade materials and employing advanced manufacturing processes to ensure reliable sealing performance and durability for every flange. Our dedicated customer service team is always available to provide assistance and guidance, ensuring your satisfaction.

If you are seeking a reliable flange supplier, YANHAO is your preferred partner. We invite you to get in touch with us to discuss your project requirements and specifications. We look forward to establishing a long-term collaboration, providing you with top-quality flange products and services.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.