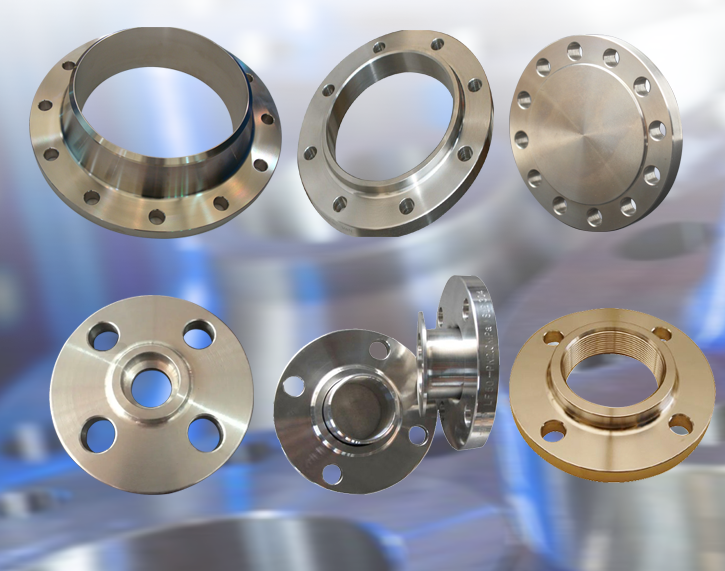

In today’s blog, we will delve into the types of flanges and their uses in different industries. This blog will introduce various common types of flanges, including weld neck flanges, slip-on flanges, socket weld flanges, lap joint flanges, blind flanges, and threaded flanges. We will also focus on the versatility of flanges and their applications in industries such as oil and gas, chemical, shipbuilding, pharmaceutical, power generation, and paper manufacturing. Let’s dive in and explore the diverse uses of flanges in these industries.

Weld Neck Flanges

Description and physical characteristics

Weld Neck Flanges are a type of flange that has a long tapered hub and a circular neck. The hub provides reinforcement to the flange, while the neck acts as a transition between the flange and the pipe. These flanges are usually butt-welded to the pipe, resulting in a strong and permanent connection.

The physical characteristics of Weld Neck Flanges include:

- Long Tapered Hub: The hub is the thicker portion of the flange and provides strength and support. Its tapered design helps to reduce stress and distribute pressure evenly.

- Circular Neck: The neck of the flange is the part that extends from the hub to connect with the pipe. It has a smaller diameter compared to the hub and helps to reduce turbulence and improve flow characteristics.

- Weld Bevel: Weld Neck Flanges have a machine-beveled end, which allows for better weld preparation. The beveled end ensures a smooth transition and facilitates a strong and reliable weld joint.

- Raised Face: Weld Neck Flanges often feature a raised face around the sealing surface. This raised area helps to create a tight seal when the flange is bolted to another flange or equipment.

- Standard Dimensions: Weld Neck Flanges are manufactured according to recognized standards, such as ASME B16.5 or EN 1092-1. These standards specify the dimensions, materials, and pressure ratings of the flanges, ensuring compatibility and interchangeability.

Overall, Weld Neck Flanges are favored for their strong and secure connection, allowing for efficient flow and withstanding high-pressure and high-temperature conditions. Their physical characteristics make them suitable for various applications in industries such as oil and gas, petrochemical, power generation, and more.

Common uses and applications

Weld Neck Flanges are widely used in various industries due to their strength, reliability, and ability to withstand high pressures and temperatures. Some common uses and applications of Weld Neck Flanges include:

- Oil and Gas Industry: These flanges are commonly used in oil and gas refineries, offshore platforms, and pipeline systems. They provide a secure and leak-proof connection for high-pressure and high-temperature applications, such as fluid transport and processing.

- Petrochemical Industry: Weld Neck Flanges are extensively used in petrochemical plants for their ability to handle corrosive fluids and withstand high pressures. They are crucial for connecting pipes and equipment in processing units, chemical reactors, and storage tanks.

- Power Generation: Weld Neck Flanges play a vital role in power plants. They are used in steam lines, gas turbine systems, and other high-pressure systems for reliable connections that can withstand the demanding conditions of power generation.

- Chemical Industry: Due to their resistance to corrosion and durability, Weld Neck Flanges are ideal for the chemical industry. They are used in the transportation and processing of corrosive chemicals, ensuring safe and leak-free operations.

- Shipbuilding: Weld Neck Flanges find extensive applications in the shipbuilding industry. They are used to connect pipes, equipment, and structures on ships and offshore platforms, providing secure and robust connections that can withstand harsh marine environments.

- Water Treatment: Weld Neck Flanges are used in water treatment plants for their ability to handle high pressures and maintain leak-free connections. They are commonly used in water transmission and distribution systems, as well as in wastewater treatment facilities.

- Construction: These flanges are also used in construction projects, such as building infrastructure, bridges, and tunnels. They provide secure connections for plumbing systems, HVAC systems, and other piping applications.

In summary, Weld Neck Flanges are versatile and widely used in industries that require reliable and durable connections for high-pressure and high-temperature applications. Their applications range from oil and gas to petrochemicals, power generation, shipbuilding, water treatment, and construction.

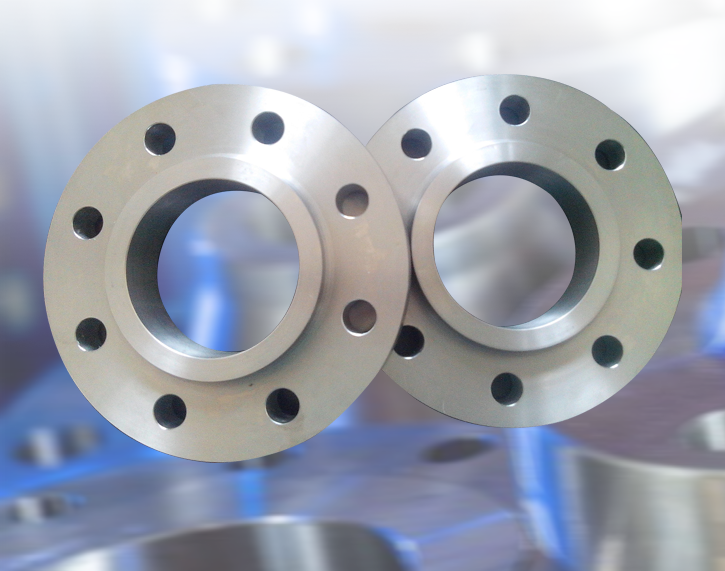

Slip-On Flanges

Description and physical characteristics

Slip-On Flanges are a type of flange that is slipped over the end of a pipe or fitting and then welded in place. They have a flat face and a raised collar or hub for easy alignment and installation. Slip-On Flanges are designed to allow for easy sliding onto the pipe and provide a strong, leak-proof connection when welded properly.

The physical characteristics of Slip-On Flanges include:

- Flat Face: Slip-On Flanges have a flat sealing face, which allows for full contact with the gasket or mating flange. The flat face provides a large sealing surface area, ensuring a secure and reliable seal.

- Raised Collar or Hub: Slip-On Flanges feature a raised collar or hub on the inner diameter. This collar provides additional thickness and strength to the flange, as well as a surface for easy alignment during installation.

- Slip-On Design: Slip-On Flanges are designed to slide over the pipe end and then be welded in place. The slip-on design facilitates quick and easy installation, making them a popular choice for applications that require frequent disassembly.

- Welding Bevel: Slip-On Flanges have a welding bevel on the inside diameter, which allows for better weld penetration and a stronger connection. The bevel also ensures a smooth transition and reduces the risk of stress concentration.

- Standard Dimensions: Slip-On Flanges are typically manufactured in accordance with recognized standards, such as ASME B16.5 or EN 1092-1. These standards specify the dimensions, materials, and pressure ratings of the flanges, ensuring compatibility and interchangeability.

- Corrosion Resistance: Slip-On Flanges are available in various materials, including carbon steel, stainless steel, and alloy steel, which offer excellent corrosion resistance. The material selection depends on the specific application and the medium being transported.

Overall, Slip-On Flanges are widely used in industries where easy installation, cost-effectiveness, and frequent disassembly are required. They are commonly utilized in low-pressure and low-temperature applications, such as water supply systems, fire protection systems, and general plumbing applications.

Common uses and applications

Slip-On Flanges are commonly used in various industries and applications. Some of the common uses and applications of Slip-On Flanges include:

- Water and Wastewater Treatment: Slip-On Flanges are commonly used in water and wastewater treatment plants for connecting pipes and equipment. They provide a secure and leak-proof connection, making them suitable for water supply systems, treatment processes, and distribution networks.

- HVAC Systems: Slip-On Flanges are widely used in heating, ventilation, and air conditioning (HVAC) systems. They are used to connect ducts, pipes, and other components in HVAC installations, ensuring a reliable and airtight connection.

- Oil and Gas Industry: Slip-On Flanges find applications in the oil and gas industry, particularly in low-pressure and non-critical systems. They are used in pipelines, storage tanks, and other equipment where easy installation and maintenance are required.

- Chemical and Petrochemical Industry: Slip-On Flanges are used in various chemical and petrochemical processing plants. They are suitable for connecting pipes, valves, and other equipment in corrosive environments where leak-proof connections are essential.

- Food and Beverage Industry: Slip-On Flanges are used in food and beverage processing plants for connecting pipes and equipment. They comply with hygiene standards and provide a secure connection for transporting food and beverage products.

- Construction and Building Services: Slip-On Flanges are commonly used in construction projects for plumbing systems, fire protection systems, and water supply networks in residential, commercial, and industrial buildings.

- Power Generation: Slip-On Flanges find applications in power plants, including thermal power plants and renewable energy facilities. They are used in low-pressure systems, such as water and steam piping, that require easy installation and maintenance.

- Shipbuilding and Marine Applications: Slip-On Flanges are used in the shipbuilding industry for connecting pipes, fittings, and equipment on ships and offshore structures. They offer ease of installation and help ensure a tight and secure connection in marine environments.

These are just a few examples of the common uses and applications of Slip-On Flanges. Due to their versatility and easy installation, they are widely utilized in various industries that require reliable and leak-proof connections for low-pressure systems.

Socket Weld Flanges

Description and physical characteristics

Socket Weld Flanges are a type of flange that is designed to be welded directly to the pipe end by inserting the pipe into the socket of the flange. They have a socket or bore that provides a smooth inner surface for inserting the pipe and a flat sealing face for creating a secure connection.

The physical characteristics of Socket Weld Flanges include:

- Socket or Bore: Socket Weld Flanges have a socket or bore on the inner diameter, which is designed to fit the outer diameter of the pipe. The socket provides a secure fit for the pipe and allows for easy alignment during welding.

- Flat Face: Socket Weld Flanges have a flat sealing face on the outside diameter. The flat face provides a large surface area for mating with the gasket or another flange, ensuring a tight and leak-proof connection.

- Counterbored Socket: Socket Weld Flanges often have a counterbored socket, which means that the socket is slightly larger in diameter than the actual pipe. This allows for a fillet weld to be made on the inside of the flange, providing additional strength and reinforcement.

- Raised Face: Some Socket Weld Flanges may have a raised face on the sealing surface. The raised face helps in centering the gasket and provides additional sealing surface area, enhancing the leak resistance of the connection.

- Welding Preparation: Socket Weld Flanges have a beveled end on the socket, which aids in achieving proper weld penetration. The beveled end allows for a full penetration weld, creating a strong joint between the flange and the pipe.

- Material and Pressure Ratings: Socket Weld Flanges are available in various materials such as carbon steel, stainless steel, and alloy steel. The material selection depends on the specific requirements of the application. They are manufactured to meet specific pressure ratings, ensuring suitability for different pressure environments.

- Size Range: Socket Weld Flanges are available in a range of sizes, typically from ½ inch to 24 inches in diameter. They are commonly used in smaller pipe sizes and low-pressure applications.

Socket Weld Flanges are commonly used in industries where high strength and reliability are required. They are widely used in applications such as petrochemical plants, oil and gas refineries, power generation, and other industrial processes. The socket weld connection allows for easy installation and maintenance, making Socket Weld Flanges suitable for systems that require frequent disassembly and reassembly.

Common uses and applications

Socket Weld Flanges have various common uses and applications across different industries. Some of the common uses and applications of Socket Weld Flanges include:

- Process Piping: Socket Weld Flanges are commonly used in process piping systems where there is a need for a reliable and leak-proof connection. They are suitable for connecting pipes in industries such as oil and gas, chemical processing, pharmaceuticals, and food and beverage.

- Power Generation: Socket Weld Flanges find applications in power generation plants, including thermal power plants and nuclear power plants. They are used to connect pipes in steam lines, water treatment systems, and other power generation equipment.

- Petrochemical Industry: Socket Weld Flanges are widely used in the petrochemical industry for connecting pipelines that transport various chemicals, gases, and liquids. They are suitable for applications that require high strength and resistance to corrosive environments.

- Oil and Gas Industry: Socket Weld Flanges are used in the oil and gas industry for connecting pipelines, fittings, and valves. They are commonly used in upstream, midstream, and downstream operations, including drilling, production, transportation, and refining processes.

- Pharmaceutical and Biotechnology: Socket Weld Flanges are used in pharmaceutical and biotechnology industries, where hygiene and cleanability are critical. They are suitable for connecting pipes in production areas, cleanrooms, and sterile processing facilities.

- Shipbuilding and Marine Applications: Socket Weld Flanges find applications in shipbuilding and marine industries. They are commonly used for connecting pipes on ships, offshore platforms, and other marine structures, providing a reliable and strong connection in harsh marine environments.

- HVAC and Plumbing Systems: Socket Weld Flanges are used in heating, ventilation, air conditioning (HVAC), and plumbing systems. They are suitable for connecting pipes, fittings, and equipment in residential, commercial, and industrial buildings.

- Water and Wastewater Treatment: Socket Weld Flanges are commonly used in water and wastewater treatment plants for connecting pipelines and equipment. They provide a tight and durable connection, ensuring efficient water treatment processes.

These are just a few examples of the common uses and applications of Socket Weld Flanges. Due to their reliable and leak-proof connection, Socket Weld Flanges are widely utilized in various industries that require strong and secure connections for pipelines and equipment.

Blind Flanges

Description and physical characteristics

Blind Flanges are a type of flange that is used to seal the end of a pipe or vessel. They are called “blind” because they have no opening or bore and effectively close off the end of a system. Blind Flanges are typically used in applications where future connections or inspections are not required.

The physical characteristics of Blind Flanges include:

- Faced or Flat Surface: Blind Flanges have a flat surface on the sealing face. This surface provides a large contact area for creating a tight seal when the flange is bolted or fastened onto the pipe or vessel.

- Thickness: Blind Flanges are usually thicker compared to other types of flanges as they need to withstand the internal pressure within the system. The thickness of the flange is determined based on the expected pressure and temperature of the system.

- Bolt Holes: Blind Flanges have bolt holes around the circumference to allow for the fastening of the flange onto the pipe or vessel. The number and size of the bolt holes depend on the flange size and pressure rating.

- Gasket Surfaces: Blind Flanges have gasket surfaces that are machined or finished to provide a smooth and even surface for the placement of a gasket. The gasket helps create a sealed connection when the flange is bolted down.

- Material and Pressure Ratings: Blind Flanges are available in a variety of materials, including carbon steel, stainless steel, and alloy steel, to suit different applications and corrosion resistance requirements. They are manufactured to meet specific pressure ratings, ensuring their suitability for different pressure environments.

- Size Range: Blind Flanges are available in a range of sizes, typically from ½ inch to 24 inches in diameter. They are commonly used in larger pipe sizes and high-pressure applications.

- Facing Types: Blind Flanges can have different face types, such as flat face (FF), raised face (RF), and ring-type joint (RTJ). The facing type is selected based on the requirements of the application, including the type of gasket used and the desired level of sealing.

Blind Flanges are commonly used in various industries and applications, including oil and gas, chemical processing, water treatment, and power generation. They are used to seal the end of pipelines, pressure vessels, tanks, and other equipment, providing a secure and watertight seal. Blind Flanges can also be used for temporary closures during maintenance or repair activities, allowing for safe isolation of the system.

Common uses and applications

Blind flanges have several common uses and applications across various industries. Some of the common uses and applications of blind flanges include:

- Isolation and Shut-off: Blind flanges are often used to isolate or shut off sections of a pipeline or vessel. They provide a solid closure, preventing the flow of fluid or gas through the system. This is useful during maintenance, repair, or inspection activities when a specific section needs to be isolated.

- Pressure Testing: Blind flanges are utilized in pressure testing procedures to check the integrity and strength of a pipeline or vessel. By closing off one end of the system with a blind flange, pressure can be applied to the other end, allowing technicians to monitor for leaks or weaknesses.

- Protection of Piping Systems: Blind flanges are used to protect the ends of piping systems from debris, dirt, or contamination. They can be installed on open-ended pipes or vessels that are temporarily out of service or awaiting connection to another system.

- Pipeline Integrity: Blind flanges are employed in pipelines to ensure the safe and secure closure of open ends. They help maintain the integrity of the pipeline by preventing leaks, reducing the risk of accidents, and protecting against environmental contamination.

- Hydrostatic Testing: Blind flanges are commonly used in hydrostatic testing of pipelines and vessels. They allow the section being tested to be sealed off, enabling the application of hydraulic pressure to assess the system’s strength and identify any potential weaknesses.

- Flange Covers: Blind flanges can be used as protective covers for flange joints. They can be installed on open flanges to provide a barrier against weathering, corrosion, or physical damage, helping to prolong the lifespan of the flange connection.

- Flow Control and Diverter Applications: Blind flanges can be employed in flow control or diverter applications where the direction of flow needs to be changed within a pipeline or vessel. By closing off one outlet or inlet using a blind flange, the flow can be redirected to another direction.

- Temporary Closure: Blind flanges are often used for temporary closures in various industries, including oil and gas, chemical processing, and power generation. They can be installed when equipment or pipelines are temporarily taken out of service for maintenance or repair.

These are some of the common uses and applications of blind flanges. Their versatility, strong sealing capabilities, and ability to provide a solid closure make them a valuable component in different industries where the closure or isolation of pipelines or vessels is required.

Threaded Flanges

Description and physical characteristics

Threaded flanges are a type of flange that have internal threads. They are designed to be connected to pipes or fittings with external threads, creating a threaded joint. Threaded flanges provide a strong and secure connection, allowing for easy installation and disassembly without the need for welding.

Here are the physical characteristics and description of threaded flanges:

- Threading: Threaded flanges have internal threads that match the external threads of pipes or fittings. The threads are typically NPT (National Pipe Thread) or BSP (British Standard Pipe) types, depending on the region or specifications.

- Raised Face (RF) or Flat Face (FF): Threaded flanges can have a raised face or a flat face sealing surface. The raised face provides a small contact area, while the flat face offers a larger surface for improved sealing.

- Bolt Holes: Threaded flanges do not have bolt holes like other flanges. Instead, they rely on the threads to create a tight seal and secure connection. The threads of the flange and pipe are tightened together using threaded couplings, typically in the form of unions or nipples.

- Material: Threaded flanges are available in various materials to suit different applications and corrosion resistance requirements. Common materials used for threaded flanges include carbon steel, stainless steel, and alloy steel.

- Size Range: Threaded flanges are available in a wide range of sizes, typically from ½ inch to 12 inches in diameter. The size of a threaded flange is determined by the pipe or fitting it is intended to connect with.

- Pressure Ratings: Threaded flanges are manufactured to meet specific pressure ratings. The pressure rating of a threaded flange depends on the material, size, and design standards. It is essential to select a threaded flange that can withstand the pressure and temperature of the intended application.

- Applications: Threaded flanges are commonly used in low-pressure and low-temperature applications. They are widely used in plumbing systems, water treatment plants, HVAC systems, and other industrial sectors where easy assembly and disassembly are required.

- Sealing: Threaded flanges rely on the threads and mating surfaces to create a seal. Thread sealants, such as PTFE tape or pipe dope, are generally applied to the threads before installation to enhance sealing and prevent leaks.

It is important to note that threaded flanges have limitations regarding pressure and temperature compared to other types of flanges, such as slip-on or weld neck flanges. They are typically used in applications where the pressure is not too high and the temperature extremes are within the material’s limitations.

Common uses and applications

Threaded flanges have several common uses and applications across various industries. Some of the common uses and applications of threaded flanges include:

- Plumbing and Pipelines: Threaded flanges are widely used in plumbing systems for connecting pipes, fittings, and valves. They provide a secure and leak-proof joint, making them suitable for residential, commercial, and industrial plumbing applications.

- HVAC Systems: Threaded flanges are commonly used in heating, ventilation, and air conditioning (HVAC) systems. They are used to connect air ducts, vents, and other components, ensuring a tight and reliable connection.

- Water Treatment Plants: Threaded flanges are utilized in water treatment plants for connecting pipes, valves, pumps, and other equipment. They provide a convenient and easy-to-install joint that can withstand the water pressure and chemical exposure typical in water treatment processes.

- Process Industries: Threaded flanges find application in various process industries, such as chemical, pharmaceutical, food and beverage, and petrochemical industries. They are used for connecting process pipes, tanks, and vessels, providing a reliable joint that can withstand the specific requirements of each industry.

- Irrigation Systems: Threaded flanges are commonly used in irrigation systems, connecting pipes, sprinklers, valves, and other irrigation components. They allow for easy installation and removal of irrigation equipment, making maintenance and repairs more convenient.

- Marine and Offshore: Threaded flanges are used in marine and offshore environments for connecting pipes and fittings in shipbuilding, offshore oil and gas platforms, and other marine applications. They offer a reliable and sturdy joint that can withstand harsh conditions and corrosive environments.

- Fire Protection Systems: Threaded flanges are employed in fire protection systems, working together with fire hydrants, fire sprinklers, valves, and pipes. They provide a secure connection that ensures the effectiveness and reliability of fire protection systems.

- General Industrial Applications: Threaded flanges are widely used in various general industrial applications where a secure and leak-proof pipe connection is required. They are found in industries such as manufacturing, power generation, mining, and more.

These are some of the commonly observed uses and applications of threaded flanges. Their versatility, ease of installation, and reliability make them suitable for a wide range of industries and applications where threaded connections are preferred or required.

Lap Joint Flanges

Description and physical characteristics

Lap joint flanges, also known as loose flanges or Van Stone flanges, are a type of flange that is used to connect pipes or fittings together. Unlike other flanges, lap joint flanges do not have a raised face or a sealing surface. Instead, they rely on a combination of a stub-end and a lap joint flange to create a joint.

Here are the physical characteristics and description of lap joint flanges:

- Stub-End: Lap joint flanges consist of two main components: the lap joint flange and the stub-end. The stub end is a short piece of pipe with a flared-out end. It is equipped with a lap joint flange on one end and a plain, unflanged end on the other.

- Backing Flange: The lap joint flange is a flat, circular disc with a tapered inside edge and bolt holes. It does not have a raised face or a contact surface. It is commonly made from materials such as carbon steel, stainless steel, or alloy steel.

- Stub-End Length: The length of the stub-end can vary depending on the application. Short stub-ends are typically used for low-pressure applications, while long stub-ends are used for higher-pressure applications or when thermal expansion needs to be accommodated.

- Alignment: Lap joint flanges are designed to allow pipe misalignment. The stub-end can rotate within the lap joint flange, providing flexibility in aligning the pipes before tightening the bolts.

- Bolt Holes: Lap joint flanges have bolt holes around the circumference, which are used to secure the flange to the pipeline or equipment using bolts. The number and size of the bolt holes depend on the flange size and pressure rating.

- Gasket: Lap joint flanges require the use of a separate gasket to provide a seal. The gasket is placed between the stub end and the mating flange face, creating a seal when the bolts are tightened.

- Floating Flange: The lap joint flange is considered a floating flange because it is not permanently attached to the pipe or equipment. It can be easily slid onto the pipe or equipment and removed when needed.

- Non-Pressure Containing: Lap joint flanges are not designed to contain pressure by themselves. They are commonly used in low-pressure applications, where the primary purpose is to allow easy disassembly and maintenance of a pipeline.

Lap joint flanges are commonly used in applications where frequent maintenance or disassembly is required, such as in piping systems that require periodic inspection or cleaning. They are also suitable for applications where there is a need to accommodate thermal expansion or alignment adjustments. Lap joint flanges are commonly used in industries such as oil and gas, chemical processing, water treatment, and food processing.

Common uses and applications

Lap joint flanges have several common uses and applications across various industries. Some of the common uses and applications of lap joint flanges include:

- Low-Pressure Systems: Lap joint flanges are commonly used in low-pressure systems where frequent disassembly and reassembly are required. They allow for easy removal and replacement of pipes or equipment without disturbing the rest of the system.

- Piping Systems with Misalignment: Lap joint flanges are used in piping systems where there may be misalignment or rotation of the pipes. The flexibility of the stub-end allows for slight movement and adjustment to align the pipes properly.

- High-Temperature Applications: Lap joint flanges are suitable for high-temperature applications where thermal expansion is a concern. The loose fit between the lap joint flange and the stub end accommodates thermal expansion, reducing the risk of leaks or damage.

- Corrosive Environments: Lap joint flanges are often used in corrosive environments, such as chemical processing plants or offshore applications, as they can be easily disassembled and replaced for maintenance or repairs.

- Swivel Joints: Lap joint flanges are used in swivel joints, which allow for rotation or movement in piping systems. They are commonly used in applications such as loading arms, hoses, or flexible connections.

- Water Treatment Plants: Lap joint flanges are frequently used in water treatment plants for connecting pipes, valves, and fittings. They allow for easy access and disassembly, enabling maintenance and repairs without disrupting the entire system.

- Exhaust Systems: Lap joint flanges are used in exhaust systems, particularly in automotive and industrial applications. They provide a secure connection that can withstand the high temperatures and vibrations associated with exhaust gases.

- Shipbuilding and Maritime Applications: Lap joint flanges are commonly used in shipbuilding and maritime applications, such as connecting pipes and fittings in pipelines, ballast systems, and fuel transfer systems. The ease of assembly and disassembly is beneficial for maintenance and repair operations.

- Food and Beverage Industry: Lap joint flanges are suitable for the food and beverage industry, where hygienic connections are necessary. They are often used in processing equipment, pipelines, or tanks.

- Petrochemical and Oil Refining: Lap joint flanges are used in the petrochemical and oil refining industries for connecting pipes and equipment. They are commonly found in storage tanks, pump systems, and processing units.

These are some of the commonly observed uses and applications of lap joint flanges. Their ability to allow for easy disassembly, alignment flexibility, and resistance to high temperatures and corrosive environments make them a preferred choice in various industries and systems.

Spectacle Blind Flanges

Description and physical characteristics

Spectacle blind flanges, also known as figure-8 blinds, are special types of flanges used in piping systems to temporarily or permanently isolate a section of the pipeline. They consist of a combination of a solid plate and a ring or spacer.

Here are the physical characteristics and description of spectacle blind flanges:

- Solid Plate: The spectacle blind flange has a solid plate in the shape of a figure-8 or an hourglass. This plate is typically made of the same material as the pipeline, ensuring compatibility and maintaining the integrity of the system.

- Ring or Spacer: The spectacle blind flange also includes a ring or spacer, which is used to hold the solid plate in place. It is a flat circular disc with holes for bolt fastening. This ring or spacer is made from materials such as carbon steel, stainless steel, or alloy steel.

- Bolt Holes: Spectacle blind flanges have bolt holes located around the circumference of the ring or spacer. These holes are used to fasten the ring or spacer to the pipeline or equipment by using bolts and nuts.

- Blinding Position: The solid plate of the spectacle blind flange can be rotated to two different positions. In one position, the solid plate aligns with the ring or spacer, allowing the flow of fluid through the pipeline. In the other position, the solid plate blocks the flow, isolating the section of the pipeline.

- Handle or Lifting Lug: Spectacle blind flanges often have a handle or a lifting lug attached to the solid plate. This allows for easy installation, removal, and rotation of the plate, particularly in larger-sized and heavier blinds.

- Pressure Rating: Spectacle blind flanges are available in various pressure ratings to suit different piping system requirements. The materials, thickness, and design of the blind should be selected based on the system’s pressure and temperature.

- Size Range: Spectacle blind flanges are available in a wide range of sizes, from small diameters to large diameters, to cater to different pipe sizes and system requirements.

- Temporary or Permanent Isolation: Spectacle blind flanges can be used for temporary or permanent isolation of sections of the pipeline. Temporary isolation may be required during maintenance, repairs, or testing, while permanent isolation may be needed to divert the flow or close off a portion of the system.

Spectacle blind flanges are commonly used in industries such as oil and gas, chemical processing, power plants, and water treatment facilities. Their ability to provide secure, leak-proof isolation of the piping system makes them valuable in situations where sectioning off a flow is necessary for safety, maintenance, or operational reasons.

Common uses and applications

Spectacle blind flanges have a wide range of uses and applications across various industries. Some of the common uses and applications of spectacle blind flanges include:

- Piping System Maintenance: Spectacle blind flanges are commonly used during maintenance or repair activities on piping systems. They allow for the temporary isolation of a section of the pipeline, preventing the flow of fluids or gases while work is being carried out.

- Pressure Testing: Spectacle blind flanges are used in the pressure testing of pipelines. By installing a spectacle blind flange in the pipeline, pressure can be applied to test the integrity and strength of the system.

- System Cleaning: Spectacle blind flanges are used to isolate a section of the pipeline during cleaning operations. This allows for the efficient cleaning of equipment, pipes, or tanks without affecting the rest of the system.

- Hydrostatic Testing: Spectacle blind flanges are used in hydrostatic testing, which involves filling the pipeline with water or another liquid to test for leaks or structural integrity. By installing a spectacle blind flange, the section to be tested can be isolated, ensuring accurate testing results.

- System Modification: Spectacle blind flanges are used when modifications or extensions are required in the piping system. By isolating a specific section with a spectacle blind flange, new connections, valves, or equipment can be easily installed without interrupting the entire system.

- Emergency Isolation: Spectacle blind flanges can be used for emergency isolation in case of leaks, ruptures, or equipment failure. By quickly closing off a section of the pipeline, operators can prevent further damage or minimize the impact on the overall system.

- Flow Diversion: Spectacle blind flanges are used to divert the flow of fluids or gases in a pipeline. By rotating the solid plate of the spectacle blind flange, the flow can be redirected to an alternate path, enabling maintenance, repairs, or system adjustments while keeping the rest of the system operational.

- Safety Applications: Spectacle blind flanges are used in safety applications where the isolation of equipment or processes is critical. This includes isolating hazardous materials, toxic substances, or high-pressure systems.

- Oil and Gas Industry: Spectacle blind flanges are extensively used in the oil and gas industry for operations such as well testing, production, and transportation. They play a vital role in wellhead connections, manifold systems, and pipeline maintenance activities.

- Chemical Processing: In chemical processing plants, spectacle blind flanges are used to isolate specific sections of pipelines during the mixing, blending, or reaction processes. This allows for greater control, flexibility, and safety in handling corrosive or hazardous materials.

These are some of the commonly observed uses and applications of spectacle blind flanges. Their versatility, ability to provide temporary or permanent isolation, and compatibility with different types of pipelines make them a preferred choice in various industries and piping systems.

Specialized Flanges (e.g., Orifice Flanges, Swivel Ring Flanges)

Brief description of specialized flanges

- Orifice Flanges: Orifice flanges are specifically designed to facilitate the measurement and control of fluid or gas flow through a pipeline. They feature a concentric or eccentric opening (known as the orifice) that allows for the insertion of an orifice plate or flow meter. The plate creates a restriction, which helps in measuring the flow rate and pressure drop. Orifice flanges are commonly used in industries such as oil and gas, chemical processing, and water treatment.

- Swivel Ring Flanges: Swivel ring flanges, also known as anchor or line blinds, are innovative flange designs that provide flexibility in piping systems. They consist of two separate parts: the hub and the rotating ring. The rotating ring can be loosened and rotated, allowing for the easy alignment of flanges, bolts, and gaskets during installation or maintenance. Swivel ring flanges are often used in offshore and onshore oil and gas applications, as well as in pipeline transportation systems.

- Expander Flanges: Expander flanges are used to connect two different size pipelines or flanges together. They have a larger outer diameter on one side and a smaller outer diameter on the other, allowing for a smooth transition between different pipe sizes. Expander flanges are commonly used in piping systems where there is a need for larger pipe diameters or for connecting flanges that are manufactured to different standards.

- Tongue and Groove Flanges: Tongue and groove flanges feature a male “tongue” and a female “groove” that interlock when the flanges are bolted together. This design provides a secure and leak-proof connection, making tongue and groove flanges ideal for high-pressure and high-temperature applications. They are commonly used in industries such as petroleum refining, chemical processing, and power generation.

- Lap Joint Flanges: Lap joint flanges consist of two main components: a stub-end and a loose or “slip-on” flange. The stub end is typically welded to the pipe, while the loose flange is used to secure the joint. Lap joint flanges allow for easy disassembly and replacement of components without disturbing the rest of the pipeline. They are commonly used in systems that require frequent maintenance or where the alignment of the flanges is critical, such as in seawater systems and offshore platforms.

These specialized flanges offer unique design features and functionality to suit specific requirements in different industries. From facilitating flow measurement to providing ease of installation and maintenance, these flanges contribute to the efficiency and reliability of various piping systems.

Common uses and applications

Here are some common uses and applications of specialized flanges:

1、Orifice Flanges:

- Measurement and control of fluid or gas flow rates

- In oil and gas production, refining, and chemical processing industries for accurate flow measurement

- Monitoring and regulating pressure drop in pipelines

- Used with orifice plates or flow meters for precise flow monitoring and control

2、Swivel Ring Flanges:

- Alignment of flanges, bolts, and gaskets during installation or maintenance

- Frequently used in offshore and onshore oil and gas industries

- Pipeline transportation systems where flexibility is required

- Helps in preventing leaks and ensuring secure connections

3、Expander Flanges:

- Connecting pipelines with different sizes or joining flanges manufactured to different standards

- Commonly used in oil and gas industries, chemical plants, and power generation facilities

- Provides a smooth transition between different pipe sizes

- Allows for easy installation, maintenance, and replacement of components

4、Tongue and Groove Flanges:

- High-pressure and high-temperature applications

- Petroleum refining, chemical processing, and power generation industries

- Offers a secure and leak-proof connection

- Resists movement and ensures a tight seal under extreme conditions

5、Lap Joint Flanges:

- Frequent maintenance or replacement requirements

- Seawater systems, offshore platforms, and other critical applications

- Easy disassembly and replacement without disturbing the rest of the pipeline

- Used when the alignment of the flanges is critical

These specialized flanges serve specific purposes and are designed to meet the demands of different industries and applications. They offer unique features and functionality that contribute to the efficient and reliable operation of piping systems.

Conclusion

In conclusion, we have discussed several types of specialized flanges and their common uses. Orifice flanges are used for flow measurement and control, swivel ring flanges facilitate easy installation and alignment, expander flanges connect different size pipelines, tongue and groove flanges provide a secure and leak-proof connection, and lap joint flanges allow for easy maintenance and replacement.

At YANHAO, we are committed to providing high-quality specialized flanges that cater to the diverse needs of different industries. Our products are designed to meet stringent quality standards and deliver reliable performance. We understand the importance of precision and efficiency in piping systems, and our flanges are engineered to meet those requirements.

If you have any flange requirements or need assistance in selecting the right specialized flanges for your applications, we encourage you to contact YANHAO. Our knowledgeable team will be happy to help and provide you with the best solutions to meet your specific needs.

Choose YANHAO for your specialized flange requirements and experience the reliability and performance that your operations demand.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.