Introduction

Flanges are integral components in a wide range of industries, playing a crucial role in connecting pipes, valves, and other equipment. As a leading manufacturer, YANHAO takes pride in its expertise and commitment to producing high-quality flanges. In this comprehensive guide, we will delve into the importance of understanding the outside diameter (OD) and inside diameter (ID) for flanges and how they contribute to secure and leak-free connections.

Flanges act as connectors, allowing for the joining of piping systems with utmost precision and reliability. The OD and ID measurements are vital to ensure compatibility between different components and create a tight seal. By exploring these dimensions in detail, we can gain a deeper understanding of their significance and the expertise that sets YANHAO apart in the flange manufacturing industry. Let us now dive into the realm of OD and ID and their impact on flange performance.

I. Understanding the Outside Diameter (OD) for Flanges

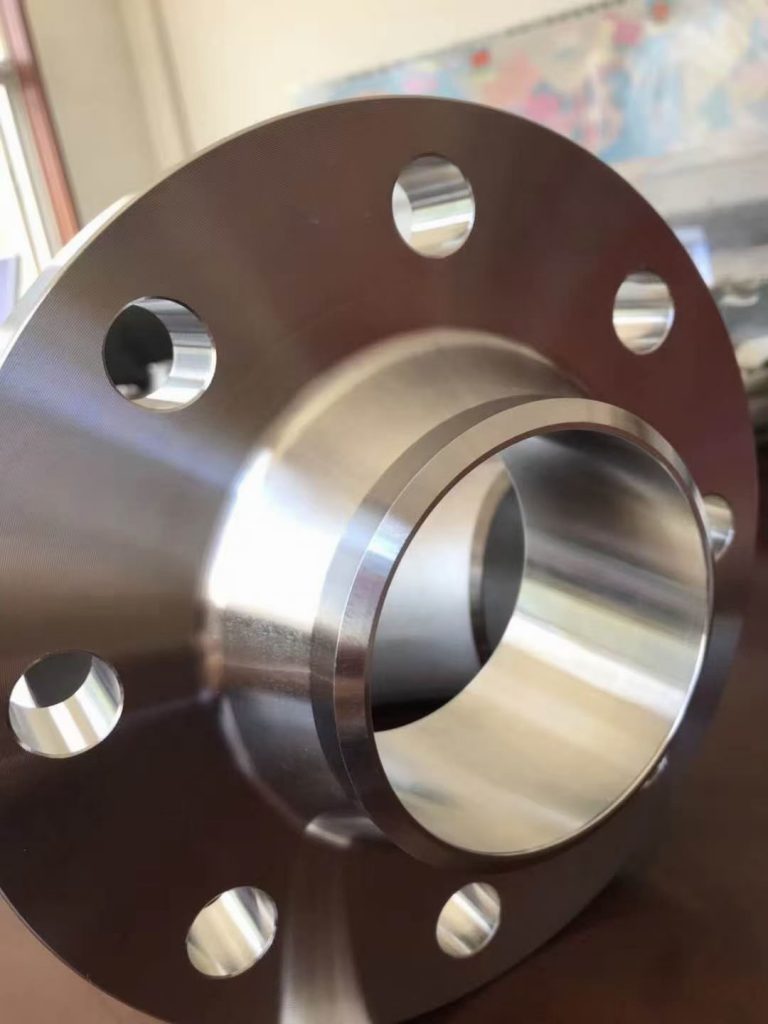

The outside diameter (OD) of a flange refers to the measurement of the outermost edge of the flange. It plays a pivotal role in determining the flange’s size and compatibility with other components. Measurement techniques like calipers or tape measures are typically used to accurately assess the OD of a flange.

The OD is crucial in ensuring that the flange fits precisely with the mating components in a piping system. It must match the outside diameter of the pipe to maintain a secure connection and prevent leakage. Additionally, the OD is a key factor in determining the overall dimensions of the flange, helping engineers select the appropriate size for their applications.

At YANHAO, we take pride in offering a wide range of flanges with precise OD measurements. Our state-of-the-art manufacturing facilities employ advanced techniques to ensure the accurate machining and finishing of flanges. With precise OD measurements, our flanges guarantee compatibility with various pipe sizes and facilitate seamless integration into different systems, enhancing efficiency and performance across diverse applications.

II. Exploring the Inside Diameter (ID) for Flanges

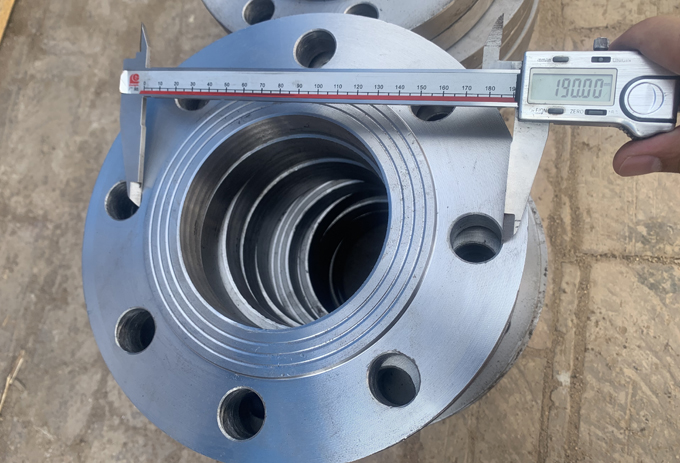

The inside diameter (ID) of a flange refers to the measurement of the innermost edge or bore of the flange. It is a critical dimension that determines the sealing area and ensures a proper connection within a piping system. The ID must correspond to the outside diameter of the pipe to create an appropriate sealing surface for gaskets or other sealing materials.

Different methods can be used to measure the ID of a flange, including specialized measuring tools like bore gauges or internal micrometers. Factors such as the flange material, manufacturing processes, and any surface finishes can influence the accuracy of the ID measurement.

YANHAO’s expertise lies in manufacturing flanges with optimal ID measurements, guaranteeing efficient sealing and reduced leakage. Our skilled technicians and advanced machinery ensure precise machining and finishing of the flanges to achieve the required ID dimensions. By paying meticulous attention to detail, we create flanges that provide a secure and leak-free connection, enhancing the integrity and functionality of piping systems in various industries.

III. OD and ID Relationship in Flanges

The relationship between the outside diameter (OD) and inside diameter (ID) of a flange is essential in determining the overall dimensions and compatibility of the flange with piping systems. While the OD represents the outermost edge of the flange, the ID represents the innermost bore.

These two dimensions work in conjunction to create a secure and leak-free connection. The OD must match the outside diameter of the pipe, ensuring proper alignment and compatibility. Meanwhile, the ID must correspond to the inside diameter of the pipe to provide an appropriate sealing area for gaskets or other sealing materials.

YANHAO acknowledges the criticality of precise OD and ID measurements in flange manufacturing. Our steadfast dedication to providing flanges with accurate dimensions reduces the likelihood of installation errors and guarantees compatibility with various piping systems. By maintaining strict quality control measures, we ensure that our flanges consistently meet the required OD and ID specifications, resulting in smooth operations and optimal performance in a wide range of industries.

IV. The Importance of Accurate OD and ID in Flanges

Accurate outside diameter (OD) and inside diameter (ID) measurements are crucial in flange manufacturing, as they directly impact the prevention of leakage, maintenance of system integrity, and overall safety. Here, we will delve into the significance of precise OD and ID measurements and how YANHAO’s flanges exemplify exceptional reliability and longevity for critical applications.

- Leakage Prevention: Flanges with accurate OD and ID measurements ensure a proper fit between mating components, promoting a secure connection and minimizing the risk of leakage. A tight seal created by matching OD and ID dimensions prevents the escape of fluids or gases, maintaining system efficiency and productivity.

- System Integrity: Flanges serve as critical components in various industries, including oil and gas, petrochemical, power generation, and water treatment. Accurate OD and ID measurements are fundamental to maintaining the overall integrity of the system. A secure connection eliminates the potential for pipe misalignment, vibration, or premature wear and tear, ensuring smooth operations and minimizing downtime.

- Safety Assurance: Flange connections are often subjected to high-pressure or high-temperature environments. In such conditions, any compromise in the accuracy of OD and ID measurements can pose serious safety risks. By manufacturing flanges with precise OD and ID dimensions, YANHAO prioritizes safety, providing customers with flanges that meet stringent industry standards and guidelines.

YANHAO stands out in the flange manufacturing industry by delivering exceptional reliability and longevity for critical applications. Our commitment to quality craftsmanship ensures that each flange we produce adheres to precise OD and ID measurements. With our flanges, customers can trust in the integrity of their systems, be confident in the prevention of leakage, and be assured of long-term safety and performance.

V. Conclusion

Understanding the importance of outside diameter (OD) and inside diameter (ID) in flanges is crucial for various industries, such as oil and gas, petrochemical, power generation, and water treatment. Accurate OD and ID measurements directly impact leakage prevention, system integrity, and safety. Flanges with precise dimensions ensure a proper fit, create a secure connection, and minimize the risk of fluid or gas leakage, maintaining system efficiency and productivity.

YANHAO, with its expertise in flange manufacturing, is committed to providing high-quality flanges with precise OD and ID measurements. By adhering to strict quality control measures, YANHAO ensures that their flanges meet industry standards, reducing installation errors, and guaranteeing compatibility with piping systems. With YANHAO flanges, customers can trust in their reliability, longevity, and safety for critical applications.

We encourage you to explore YANHAO’s comprehensive range of flanges to find the perfect solution for your specific requirements. Whether it is for high-pressure or high-temperature applications, YANHAO’s flanges offer exceptional performance and sealing capabilities for a wide range of industries. Contact YANHAO today to discover how their expertise in flange manufacturing can meet your needs effectively and reliably.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.