Introduction

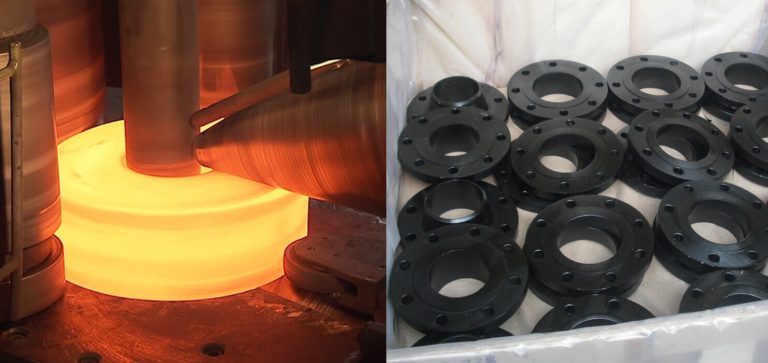

Flanges are essential components in piping systems that connect pipes and valves, allowing for efficient fluid transportation. Flanges are used extensively in various industries, such as oil and gas, chemical, and water treatment. As one of the largest producers of flanges in the world, China’s flange industry has been growing rapidly over the past decades. This article aims to explore the importance of supporting Chinese flange manufacturers and enterprises, highlighting their advantages and contributions to the global market.

Contributions of Chinese Flange Manufacturers and Enterprises to the Global Market

Chinese flange manufacturers and enterprises have made significant contributions to the global market. Here are some of the notable contributions:

- Competitive Pricing: Chinese flange manufacturers offer quality products at competitive prices, enabling customers to reduce costs without compromising on quality.

- Innovation: Chinese flange manufacturers have been investing in research and development, striving to develop new products and technologies. For example, some manufacturers are developing new materials for flange production to enhance product performance and durability.

- Job Creation: The growth of the flange industry in China has created job opportunities and contributed to the local economy. Yanhao, for instance, has eight pipe-fitting production lines and five flange production lines, with an annual production capacity of over 80,000 tons, creating numerous job opportunities for the local community.

The Advantages of Choosing Chinese Flange Manufacturers and Enterprises

Chinese flange manufacturers and enterprises offer many advantages over their competitors in other countries. Some of the benefits of choosing Chinese flange manufacturers include:

- Cost-effective: Chinese flange manufacturers offer cost-effective solutions due to lower labor costs, lower raw material costs, and favorable government policies that encourage foreign investment.

- Wide range of products: Chinese flange manufacturers produce a wide range of products, including standard and non-standard flanges, pipe fittings, and valves. They also offer customization services to meet the specific needs of their clients.

- High-quality products: Chinese flange manufacturers have invested heavily in quality control systems to ensure that their products meet the highest international standards. They use advanced testing equipment, such as X-ray machines, ultrasonic testing machines, and spectral analyzers to ensure that their products are of the highest quality.

- Quick delivery: Chinese flange manufacturers have a well-established supply chain that allows them to deliver products quickly and efficiently. They have established partnerships with logistics companies that specialize in international shipping, which ensures that products are delivered on time and in good condition.

- Rich experience: Many Chinese flange manufacturers have been in the industry for decades and have accumulated rich experience in the manufacturing of flanges and related products. They have a deep understanding of the needs of their clients and can provide valuable advice on product design and development.

Conclusion

In recent years, Chinese flange manufacturers and enterprises have been making great strides in the global market. With the help of advanced technology, improved quality control measures, and highly skilled labor, these companies are producing flanges that meet or exceed international standards. As a result, the demand for Chinese flanges has been steadily increasing around the world.

However, despite the impressive progress made by Chinese flange manufacturers and enterprises, there are still many challenges that must be overcome in order to further promote and support this industry. For example, there is still a lack of awareness about the quality and reliability of Chinese-made flanges among some international buyers, which can limit their willingness to purchase these products. Additionally, there are still some concerns about the environmental impact of manufacturing processes used in China, which can create barriers to entry for Chinese manufacturers in some markets.

To address these challenges, it is important to support Chinese flange manufacturers and enterprises by promoting their products and highlighting their advantages. One key advantage of Chinese flanges is their cost competitiveness. With lower labor costs, lower raw material costs, and strong government support for the industry, Chinese flange manufacturers are able to offer high-quality products at competitive prices. Additionally, Chinese flange manufacturers are increasingly investing in research and development, which is leading to new innovations and improved product quality.

Another advantage of Chinese flange manufacturers and enterprises is their ability to customize products to meet the unique needs of customers. With a range of advanced equipment and highly skilled labor, Chinese manufacturers can produce a wide variety of flanges in different sizes, materials, and designs. This flexibility allows Chinese manufacturers to provide tailored solutions for customers, which can help them win contracts and gain a competitive edge in the global market.

In order to further support Chinese flange manufacturers and enterprises, it is important to promote greater collaboration and knowledge-sharing between Chinese and international companies. By working together, Chinese and international companies can share expertise, technology, and best practices, which can help to improve the quality and reliability of Chinese-made flanges. Additionally, greater collaboration can help to build trust and understanding between Chinese and international companies, which can help to overcome some of the concerns and biases that still exist in the global market.

In conclusion, supporting Chinese flange manufacturers and enterprises is essential for promoting the growth and development of this industry. By highlighting the advantages of Chinese-made flanges, promoting collaboration and knowledge-sharing, and addressing concerns about quality and reliability, we can help to build a stronger, more competitive, and more sustainable global flange industry. As such, it is crucial that we continue to support and invest in this important sector.

Sources:

- “China Flange Market Size and Forecast by Type and Application” – MarketsandMarkets™

- “China flange industry, 2020” – ResearchInChina

- “Flange Manufacturing in China” – ThomasNet

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.