I. Introduction

A brief overview of the company and its production capacity

Our company is a flange manufacturer based in Cangzhou, Hebei, China. We have eight production lines for pipe fittings and five production lines for flanges, with an annual production capacity of over 80,000 tons. Our product range includes flanges and pipe fittings in various standards, such as ANSI/ASME, DIN, JIS, and non-standard sizes. We use a variety of materials in our products, including stainless steel flange, alloy steel flange, and carbon steel flange, and we offer customization options to meet our customers’ unique requirements.

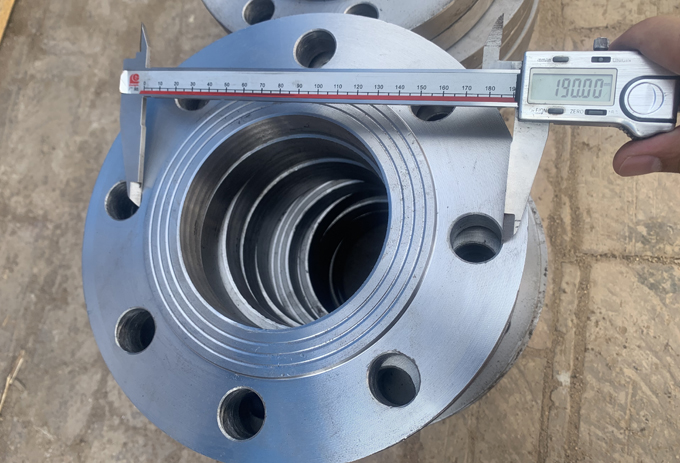

Our production process is carried out with the help of advanced technology and specialized equipment, which ensures high precision and accuracy in our products. We also have a full range of quality assurance measures in place, including physical and chemical testing systems, non-destructive testing, heat treatment, hydrostatic testing, and other product quality inspection methods. Our commitment to quality ensures that our products meet global standards and have a high level of customer satisfaction.

Overall, our company has a strong production capacity and a reputation for producing high-quality flanges and pipe fittings, making us a trusted partner for businesses looking for reliable and customizable solutions in the industry.

Importance of flanges and pipe fittings in the global market

Flanges and pipe fittings are essential components in many industries, including oil and gas, petrochemicals, water treatment, and construction. They are used to connect pipes, valves, pumps, and other equipment, creating a secure and leak-proof system. Without flanges and pipe fittings, it would be impossible to transfer fluids and gases through pipelines and maintain the safety and efficiency of the system.

In the global market, flanges and pipe fittings are in high demand due to the increasing industrialization and infrastructure development in many countries. As a result, the global flanges and pipe fittings market is expected to grow significantly in the coming years.

The importance of flanges and pipe fittings is not only limited to their functional role but also their impact on safety and environmental protection. Poor quality flanges and pipe fittings can lead to equipment failure, spills, and leaks, which can cause serious harm to workers, the environment, and the public. Therefore, it is essential to use high-quality and reliable flanges and pipe fittings in all industrial applications.

As the demand for flanges and pipe fittings continues to grow, the importance of producing high-quality and customizable products at a competitive price becomes even more critical. This is where companies like yours come in, providing reliable and high-quality solutions that meet the needs of industries around the world.

Chinese-made flanges and pipe fittings are gaining popularity in global markets due to their competitive pricing, high quality, and customization options. Chinese manufacturers have invested heavily in advanced technology and equipment, as well as quality assurance measures, to meet the increasing demand for flanges and pipe fittings worldwide. As a result, more and more businesses are turning to Chinese manufacturers for reliable and cost-effective solutions.

II. Quality Assurance Measures

the company’s quality assurance measures

Our quality assurance measures include:

Physical and chemical testing systems: We use advanced equipment to perform various physical and chemical tests on our products to ensure that they meet the required specifications. These tests include chemical composition analysis, mechanical property testing, and metallographic testing.

Non-destructive testing: We also use non-destructive testing methods such as ultrasonic testing, magnetic particle testing, and dye penetrant testing to detect any surface or internal defects in our products.

Heat treatment: Heat treatment is an essential process in the production of high-quality flanges and pipe fittings. We use specialized heat treatment equipment and processes to ensure that our products have the required strength, toughness, and durability.

Hydrostatic testing: We perform hydrostatic testing on our products to ensure that they can withstand the required pressure and are leak-proof.

Other product quality inspection methods: We also have other product quality inspection methods in place, such as visual inspection, dimensional inspection, and surface finish inspection.

By implementing these quality assurance measures, we can ensure that our products meet the highest standards of quality and reliability. We believe that our commitment to quality is one of the reasons why our Chinese-made flanges and pipe fittings are gaining popularity in global markets.

Quality assurance measures are critical in building customer trust and confidence in the products. Customers expect high-quality products that are reliable, safe, and meet their specific requirements. By implementing quality assurance measures, manufacturers can demonstrate their commitment to delivering products that meet these expectations.

When customers trust the quality of a product, they are more likely to make repeat purchases and recommend the product to others. On the other hand, poor-quality products can damage a company’s reputation and lead to lost business.

Quality assurance measures can also help to identify and address potential issues before they become major problems. By detecting defects early, manufacturers can avoid costly recalls, warranty claims, and other negative consequences that can result from defective products.

Furthermore, quality assurance measures can help to ensure compliance with industry regulations and standards. Customers rely on manufacturers to provide products that meet these requirements, and failure to do so can result in legal and financial consequences.

In summary, implementing quality assurance measures is essential for building customer trust and confidence in products. It can lead to increased customer loyalty, a positive brand reputation, and a competitive advantage in the global market.

III. Material Variety and Customization Options

Application of different materials in flange fittings

Flanges and pipe fittings can be made from a variety of materials, each with its own unique properties and characteristics. The following are some of the most commonly used materials in flanges and pipe fittings production:

Stainless steel: Stainless steel is a popular material for flanges and pipe fittings due to its high strength, corrosion resistance, and durability. It is also resistant to high temperatures, making it suitable for use in applications that involve high heat or pressure.

Alloy steel: Alloy steel is a type of steel that has been mixed with other elements to enhance its properties. Alloy steel flanges and pipe fittings offer superior strength, durability, and resistance to corrosion, making them ideal for use in demanding applications such as oil and gas pipelines and chemical processing plants.

Carbon steel: Carbon steel is a type of steel that contains carbon as the main alloying element. It is commonly used in flanges and pipe fittings due to its high tensile strength, low cost, and versatility. Carbon steel flanges and pipe fittings are also highly resistant to shock and vibration, making them suitable for use in industrial applications.

Overall, the choice of material for flanges and pipe fittings production depends on the specific application requirements, such as the type of fluid or gas being transported, the temperature and pressure of the system, and the level of corrosion resistance needed. Manufacturers must carefully select the appropriate material for each application to ensure that the flanges and pipe fittings meet the required performance standards.

Benefits of having a wide range of materials and customization options to meet diverse customer needs

Having a wide range of materials and customization options in flanges and pipe fittings production is essential for meeting diverse customer needs. Some of the benefits of offering a variety of materials and customization options include:

Meeting specific application requirements: Different industries and applications require specific types of materials and configurations for flanges and pipe fittings. Offering a wide range of materials and customization options enables manufacturers to meet these specific requirements and provide tailored solutions for customers.

Improved performance and durability: By selecting the appropriate materials and customization options for each application, manufacturers can ensure that their flanges and pipe fittings offer optimal performance, durability, and reliability. This can lead to increased customer satisfaction and loyalty.

Competitive advantage: Offering a wide range of materials and customization options can provide a competitive advantage in the global market. By providing unique solutions that meet specific customer needs, manufacturers can differentiate themselves from competitors and establish a strong reputation for quality and innovation.

Flexibility and adaptability: Markets and customer needs can change rapidly, and manufacturers must be able to adapt quickly to stay competitive. Having a wide range of materials and customization options enables manufacturers to respond to changing market demands and provide innovative solutions for emerging applications.

Overall, offering a wide range of materials and customization options is essential for meeting diverse customer needs and staying competitive in the global market. Manufacturers must invest in research and development to continue to expand their product offerings and provide tailored solutions that meet the evolving needs of their customers.

Examples of custom flange and pipe fitting designs the company has produced to meet specific customer requirements

Non-standard shapes and sizes: Flanges and pipe fittings may need to be customized to fit unique equipment configurations or to comply with specific industry standards.

Corrosion-resistant coatings: Depending on the application, flanges and pipe fittings may need to be coated with a specific material to protect against corrosion and extend the lifespan of the product.

High-temperature and high-pressure applications: Flanges and pipe fittings designed for use in high-temperature or high-pressure environments may need to be customized to withstand extreme conditions.

Specialized connections and fastenings: Custom designs may include specialized connections and fastenings to ensure a secure and reliable seal.

Unique material requirements: Depending on the fluid or gas being transported, flanges and pipe fittings may need to be made from specific materials that meet certain chemical or mechanical requirements.

By producing custom designs, manufacturers can provide tailored solutions that meet the specific needs of their customers. This can lead to increased customer satisfaction, improved performance, and a competitive advantage in the global market.

IV. Competitive Pricing

YanHao is able to offer competitive prices without sacrificing quality

As a flange and pipe fitting manufacturer based in China, YANHAO has a significant advantage in terms of production cost due to China’s lower manufacturing costs. This allows us to offer competitive pricing while maintaining high-quality products. In addition, we are located in Hebei province, which is a major production base for flanges in China. This gives us access to a wide range of high-quality raw materials at a lower cost.

Furthermore, our strong production capacity and efficient management system enable us to optimize production processes, reduce costs, and maintain consistent quality. We constantly upgrade our equipment and adopt advanced technologies to improve efficiency and reduce costs.

At YANHAO, we also have a strong R&D team and technical support team that can provide customized product designs and manufacturing to meet the unique needs of our customers. We are committed to delivering high-quality products at competitive prices without compromising quality.

The advantage of China’s lower production costs compared to other countries

China has long been known for its lower production costs compared to other countries, particularly in the manufacturing sector. There are several reasons why China has this advantage:

Labor costs: China has a large labor force, and labor costs are generally lower than in many other countries. This is due in part to the large population and the availability of skilled and unskilled workers.

Raw material costs: China is a major producer of raw materials such as steel, copper, and aluminum. This gives Chinese manufacturers easier and more affordable access to these materials, which can significantly lower production costs.

Infrastructure: China has invested heavily in its infrastructure, including roads, ports, and other transportation facilities. This makes it easier and more affordable to move raw materials and finished products around the country and to export them to other countries.

Government support: The Chinese government provides support to manufacturers in various forms, including tax breaks, subsidies, and access to loans. This helps to reduce production costs and increase competitiveness.

All of these factors give Chinese manufacturers a significant advantage in terms of lower production costs, which can lead to more competitive pricing and increased market share. However, it is important to note that lower costs must not come at the expense of quality or safety, and manufacturers must ensure that their products meet the necessary standards and regulations.

V. Expertise and Experience

YANHAO’s professional knowledge and experience in the flange and pipe fittings industry

YANHAO has extensive professional knowledge and experience in the flange and pipe fittings industry, having been in the business for many years. The company is located in Cangzhou, Hebei Province, which is known as the “hometown of flanges” in China, and is a major production base for flanges and pipe fittings in the country.

YANHAO has a team of experienced engineers and technicians who are knowledgeable in the design, production, and quality control of flanges and pipe fittings. The company’s production facilities include eight pipe-fitting production lines and five flange production lines, with an annual production capacity of over 80,000 tons. The company produces a wide range of flanges and pipe fittings that conform to various standards, including ANSI, DIN, JIS, BS, and GB.

In addition to its production capabilities, YANHAO has a strong focus on quality control, with a full set of physical and chemical testing equipment, including spectroscopy, ultrasonic testing, heat treatment, hydrostatic testing, and more. The company’s products are subject to rigorous testing to ensure that they meet the highest quality standards, and YANHAO has obtained various certifications, such as ISO9001, PED, AD2000, and TUV.

YANHAO’s professional knowledge and experience in the flange and pipe fittings industry, combined with its strong production and quality control capabilities, enable the company to provide its customers with high-quality products at competitive prices. The company has established long-term relationships with customers both domestically and internationally and has gained a reputation for excellence in the industry.

We have skilled labor and professional production equipment

YANHAO has a team of skilled and experienced workers who are well-trained in the production of flanges and pipe fittings. The company also has a variety of professional production equipment to support its operations.

The production equipment at YANHAO includes a range of machineries such as lathes, CNC machines, forging machines, welding machines, and cutting machines. The company also has a variety of testing equipment, including non-destructive testing equipment, hydrostatic testing equipment, and spectrometers.

The skilled labor and professional production equipment at YANHAO allow the company to produce high-quality flanges and pipe fittings efficiently and effectively. The production process is closely monitored by the company’s experienced technicians to ensure that the products meet the highest quality standards.

In addition, YANHAO is committed to investing in research and development to continuously improve its production processes and products. The company is constantly exploring new technologies and materials to enhance the quality of its products and provide customers with better solutions.

Overall, YANHAO’s skilled labor and professional production equipment are key factors in the company’s ability to produce high-quality flanges and pipe fittings that meet the needs of its customers. The company’s commitment to quality and continuous improvement ensures that it remains a leading supplier in the industry.

Years of experience allow us to produce high-quality flanges to global standards

YANHAO has been in the flange and pipe fittings industry for many years and has accumulated a wealth of experience in the production and testing of flanges. This experience has allowed the company to develop a deep understanding of the requirements and standards for flanges in various industries and markets around the world.

YANHAO has a team of experienced engineers and technicians who oversee every stage of the production process, from the selection of raw materials to the final inspection of finished products. The company uses advanced production technologies and testing equipment to ensure that its flanges meet or exceed the quality standards required by customers.

In addition, YANHAO has a strong focus on quality control and continuous improvement. The company has established a strict quality management system that covers all aspects of production, from raw materials and processing to packaging and delivery. This system ensures that the products produced by YANHAO are of consistently high quality and meet customer requirements.

To further ensure the quality of its flanges, YANHAO also conducts regular tests and inspections on its products. These include non-destructive testing, hydrostatic testing, and chemical composition analysis. This allows the company to identify and rectify any defects or issues before the products are shipped to customers.

Overall, YANHAO’s years of experience in the industry, combined with its commitment to quality control and continuous improvement, enable the company to produce high-quality flanges that meet global standards. The company’s expertise and dedication to excellence have earned it a reputation as a trusted and reliable supplier of flanges and pipe fittings.

VI. Conclusion

In summary, Chinese-made flanges and pipe fittings are gaining popularity in global markets for several reasons. Firstly, the implementation of quality assurance measures, including physical and chemical testing, helps to build customer trust and confidence in the products. Secondly, the availability of a wide range of materials such as stainless steel, alloy steel, and carbon steel, as well as customization options, enables companies to meet diverse customer needs. Additionally, Chinese manufacturing benefits from lower production costs due to the country’s production and labor advantages. Finally, companies like YANHAO have years of experience and professional expertise in the flange and pipe fitting industry, allowing them to produce high-quality products to global standards. These factors all contribute to the growing demand for Chinese-made flanges and pipe fittings in global markets.

In today’s globalized economy, promoting Chinese-made products to the world is essential for businesses to grow and thrive. As China continues to improve its manufacturing capabilities and quality control measures, Chinese-made products, including flanges and pipe fittings, are becoming increasingly competitive in the global market. Companies like YANHAO are committed to maintaining high-quality standards to meet the demands of customers worldwide. By providing high-quality products at competitive prices, YANHAO is well-positioned to continue to expand its market share and become a leader in the flange and pipe fitting industry. With a strong commitment to quality and customer satisfaction, YANHAO is poised to meet the needs of customers both now and in the future.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.