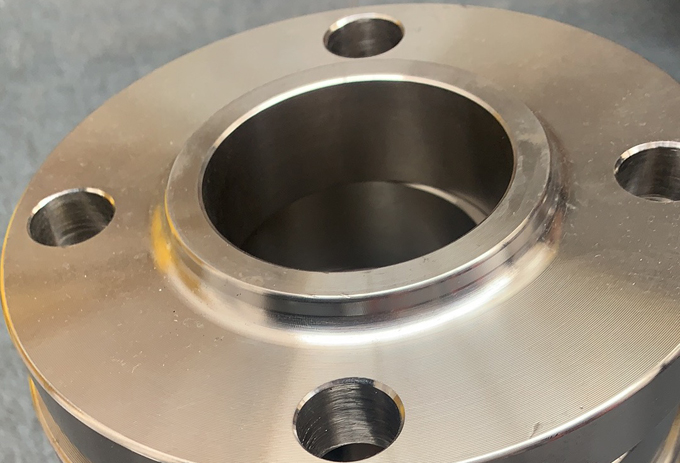

How are two flanges secured together?

This article provides a detailed explanation of the flange connection process, important considerations, and even provides information on the tools needed for flange connection preparation. We hope this is helpful for your flange connections.