In this blog, we delve deep into the realm of ANSI flange ratings, focusing particularly on the distinctions between the 150 flange and its higher-rated counterpart, the 300 flange.

What Are Flanges and Their Significance

Flanges, often regarded as the unsung heroes of piping systems, serve as integral components that facilitate the seamless functioning of industrial infrastructure. Understanding their definition and primary function is pivotal for anyone navigating the complex landscape of engineering.

Definition of Flanges:

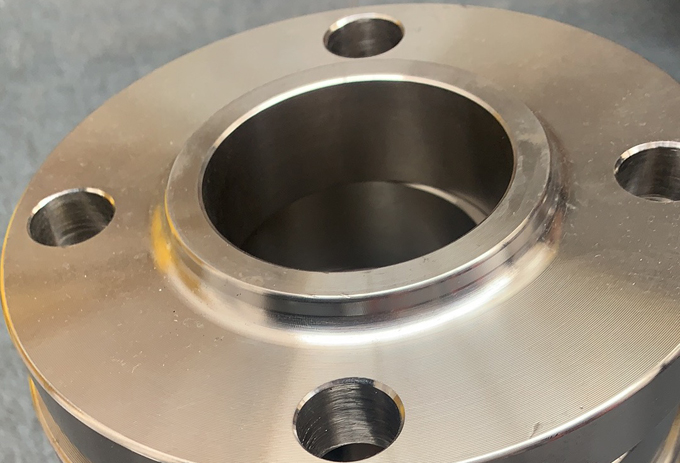

- Flanges are essential connecting components designed to join sections of pipes or connect pipes to various apparatus, valves, or equipment.

- Their versatility extends to applications in diverse industries, including petrochemical, oil and gas, water treatment, and beyond.

Primary Function of Flanges in Piping Systems:

- Connection Integrity: Flanges provide a robust and secure connection point between pipes and other components, ensuring a leak-proof and reliable infrastructure.

- Facilitation of Maintenance: Their design allows for easy disassembly, facilitating maintenance, repairs, or modifications to the piping system without extensive downtime.

- Pressure Containment: Flanges contribute significantly to maintaining pressure integrity within the system, playing a critical role in preventing leaks or structural failures.

Importance of Selecting the Right Flange:

- Optimal Performance: The right flange selection is paramount for achieving optimal performance tailored to the specific requirements of a project.

- Safety Considerations: In the realm of industrial operations, safety is non-negotiable. Choosing the correct flange ensures the overall safety and reliability of the piping system.

- Compliance with Standards: Selecting flanges that align with industry standards and specifications is crucial for compliance, ensuring the longevity and efficiency of the entire system.

In essence, comprehending the role of flanges in connecting, securing, and maintaining the integrity of piping systems lays the foundation for informed decision-making in industrial applications. Yanhao recognizes this significance, and as we delve deeper into the world of flanges, we aim to equip our audience with the knowledge necessary for making strategic and informed choices in their respective fields.

Exploring ANSI Flange Ratings

The backbone of reliability in the world of flanges lies in adherence to standards, and ANSI flange ratings stand tall as a cornerstone in this regard. Let’s embark on a journey to understand the significance of ANSI flange ratings and how they serve as the bedrock of reliability in industrial applications.

Introduction to ANSI Flange Ratings:

- ANSI, the American National Standards Institute, sets the benchmark for consistency and quality in the industry.

- ANSI flange ratings establish a standardized system, ensuring uniformity in the design, dimensions, and performance of flanges across various applications.

Overview of Flange Classification Based on Pressure Ratings:

- Pressure Ratings Defined: Flanges are classified into different pressure ratings to indicate their capacity to withstand internal pressures. ANSI classes, such as 150, 300, 600, etc., signify the pressure-bearing capacity in pounds per square inch (psi).

- Common ANSI Flange Ratings: A brief overview of the most common ANSI flange ratings, including their typical applications and pressure ranges.

- Visual Representation: Understanding the classification through a graphical representation, simplifying the complex landscape of ANSI flange ratings.

By comprehending ANSI flange ratings, engineers and decision-makers gain a roadmap for selecting the appropriate flanges based on the operational demands of their projects. As we venture into this exploration, Yanhao remains dedicated to illuminating the path towards informed decision-making in the realm of flange solutions. Stay tuned as we unravel the specifics of 150 and 300 flanges, guiding you through the maze of industrial standards and ensuring a steadfast foundation for your projects.

Understanding the 150 Flange

Delving into the specifics of the 150 flange is essential for anyone navigating the intricate landscape of industrial piping systems. In this section, we embark on an in-depth exploration, shedding light on the intricacies of the 150 flange, its pressure rating, common applications, and the crucial factors to consider when making this choice.

Pressure Rating and Design:

- Defining ANSI 150: The ANSI 150 flange, with a pressure rating of 150 pounds per square inch (psi), is a standard class known for its versatility and applicability across various industries.

- Working Parameters: Understanding the operational conditions under which the 150 flange excels, including considerations for temperature, fluid type, and system pressure.

Common Applications:

- Petrochemical Industry: The 150 flange finds widespread use in petrochemical plants for connecting pipelines carrying substances like crude oil and natural gas.

- Water Treatment Facilities: Its reliability makes it a preferred choice in water treatment applications, where durability and corrosion resistance are paramount.

Considerations When Choosing a 150 Flange:

- System Requirements: Assessing the specific demands of the piping system, considering factors such as pressure, temperature, and the nature of transported substances.

- Material Selection: Choosing materials compatible with the conveyed substances to ensure longevity and corrosion resistance.

- Cost-Efficiency: Evaluating the cost-effectiveness of the 150 flange for the intended application, factoring in initial costs and long-term maintenance considerations.

As we navigate through the intricacies of the 150 flange, Yanhao underscores the importance of informed decision-making. By understanding its pressure rating, applications, and critical considerations, engineers and project managers can confidently integrate the 150 flange into their systems, ensuring reliability and performance. Stay tuned as we continue our journey into the realm of flange expertise.

Delving into the 300 Flange

In this section, we embark on a detailed exploration of the formidable ANSI 300 flange, unearthing its exceptional characteristics and discerning its optimal applications. We also draw insightful comparisons with its counterpart, the 150 flange, unraveling the distinct scenarios where each excels and acknowledging potential limitations.

Higher Pressure Rating and Performance Excellence:

- Defining ANSI 300 Flange: With a robust pressure rating of 300 pounds per square inch (psi), the 300 flange stands as a stalwart in high-pressure environments.

- Optimal Performance: Emphasizing how the higher pressure rating of the 300 flange makes it a go-to choice for applications demanding resilience against elevated pressures.

Specific Use Cases:

- Oil and Gas Sector: The 300 flange finds its stride in upstream oil and gas operations, where it ensures the integrity of critical pipelines under intense pressures.

- Chemical Processing: Its resilience makes it a preferred choice in chemical processing plants, dealing with corrosive substances and high-pressure conditions.

Comparisons with the 150 Flange:

- Applications: Unveiling scenarios where the 300 flange outshines the 150 flange, particularly in environments with stringent pressure requirements.

- Limitations: Recognizing situations where the 300 flange may be over-specification, leading to increased costs without proportional benefits.

As we navigate through the intricacies of the 300 flange, Yanhao aims to provide a nuanced understanding of its applications, ensuring that engineering decisions align precisely with project requirements. Stay tuned for a comparative analysis that elucidates the strengths and limitations of both the 300 and 150 flanges, facilitating informed choices for your industrial systems.

Key Differences and Decision-Making Criteria

In this pivotal section, we embark on a detailed analysis of the critical distinctions between the 150 and 300 flanges. The aim is to empower decision-makers with insights that will guide the selection process, ensuring that flange choices align seamlessly with the unique demands of individual projects.

- Analyzing Critical Distinctions:

- Pressure Handling: Unveiling the primary divergence in pressure ratings, where the 150 flange is tailored for moderate pressures, while the 300 flange excels in high-pressure environments.

- Material Considerations: Exploring the impact of material specifications on corrosion resistance and durability, highlighting variations that significantly influence the performance of each flange.

- Factors Influencing Flange Choice:

- Project-Specific Requirements: Emphasizing the need to align flange selection with project-specific parameters, including the nature of fluids, operating temperatures, and pressure thresholds.

- Cost-Benefit Analysis: Providing insights into conducting a thorough cost-benefit analysis, ensuring that the selected flange meets performance criteria without unnecessary over-specification, thereby optimizing costs.

- Future Scalability: Considering the scalability of the chosen flange for potential expansions or modifications in the system, ensuring adaptability to future project requirements.

As we dissect the key differences, Yanhao endeavors to offer valuable insights that transcend the technicalities, enabling decision-makers to make judicious choices. Stay tuned for a synthesis of knowledge that will serve as a compass in the decision-making process, guiding you towards optimal flange selections for your industrial endeavors.

Yanhao’s Expertise in Flange Solutions

In this section, we take a moment to shine a spotlight on Yanhao’s unwavering commitment to delivering exceptional flange solutions. Our dedication to quality and expertise sets us apart as a reliable partner for those seeking precision and reliability in their industrial projects.

Commitment to Quality:

- Craftsmanship Excellence: Yanhao prides itself on meticulous craftsmanship, ensuring that every flange produced meets stringent quality standards.

- Material Selection: Our commitment extends to the careful selection of materials, guaranteeing not only compliance with industry norms but also optimal performance in diverse environments.

Expertise and Reputation:

- Industry Recognition: Yanhao has garnered a reputation for excellence within the industry, recognized for providing innovative and reliable flange solutions.

- Diverse Industrial Solutions: With a wealth of experience, Yanhao has demonstrated expertise in catering to the unique needs of various industries, from petrochemicals to water treatment.

Customer-Centric Approach:

- Tailored Solutions: Understanding that every project is unique, Yanhao adopts a customer-centric approach, offering tailored solutions that align precisely with the requirements of our clients.

- Responsive Support: Our commitment doesn’t end with product delivery; we provide ongoing support, ensuring that our clients have a reliable partner throughout their project lifecycle.

As we accentuate Yanhao’s dedication to excellence, we invite you to experience firsthand the reliability and precision that have become synonymous with our brand. In choosing Yanhao, you choose a partner committed to not just meeting but exceeding your expectations in the realm of flange solutions.

Conclusion

In the culmination of our exploration into the realms of 150 and 300 flanges, let’s distill the insights gained and underscore the significance of making informed decisions in the world of industrial flange solutions.

Key Takeaways:

- Pressure Distinctions: The pivotal difference between the 150 and 300 flanges lies in their pressure-handling capabilities, with the 150 suitable for moderate pressures and the 300 excelling in high-pressure environments.

- Application Variances: Understanding the specific applications where each flange thrives, whether in petrochemicals, water treatment, oil and gas exploration, or chemical processing.

- Decision-Making Criteria: Factors such as project requirements, cost-benefit analyses, and considerations for future scalability play crucial roles in selecting the optimal flange.

As you navigate the complex decision-making process in selecting flanges, remember that knowledge is your greatest ally. Make choices that resonate with the unique demands of your projects, and consider Yanhao as your dedicated partner in achieving excellence in industrial flange solutions. Thank you for joining us on this journey of exploration and expertise.

Lewis Liu

Hello, I am Lewis Liu, a professional sales engineer with over ten years of experience in the flange fittings industry. I am highly knowledgeable in flange selection, installation, and maintenance. I am passionate about providing customers with the best solutions to ensure their pipeline systems run smoothly, safely, and reliably.

If you have any questions or concerns regarding flange fittings for your pipelines, whether it’s about selection, material choice, specification requirements, or any other aspect, please feel free to contact me at any time. I am committed to offering professional advice and assistance to help you make informed decisions and meet your needs.